The International Convention for the Prevention of Pollution from Ships, MARPOL, is a key international marine environmental convention aimed at minimizing pollution of the oceans and seas from ships. This includes pollution from oil, chemicals, garbage, sewage, and air emissions. The MARPOL Convention has evolved through various amendments to address emerging environmental challenges and now consists of several annexes, each targeting different types of pollution.

MARPOL Annex VI, officially known as the “Prevention of Air Pollution from Ships,” is a vital component of this convention. Introduced in 1997 and enforced in 2005, Annex VI sets forth stringent regulations and guidelines to limit harmful emissions from ships, specifically targeting the release of sulfur oxides (SOx), nitrogen oxides (NOx), ozone-depleting substances (ODS), and volatile organic compounds (VOCs).

On January 1, 2020, the International Maritime Organization (IMO) implemented a global sulfur cap of 0.5% m/m (mass by mass) on marine fuels under MARPOL Annex VI, significantly reducing the allowed sulfur content in ship emissions. In Emission Control Areas (ECAs), stricter regulations apply, requiring ships to use fuels with a maximum sulfur content of 0.1% m/m. To comply, ships operating in ECAs typically use Marine Gas Oil (MGO) or Ultra-Low Sulfur Fuel Oil (ULSFO). In non-ECA waters, ships may use Very Low Sulfur Fuel Oil (VLSFO), compliant Marine Fuel Oil (MFO), or install SOx scrubbers to continue using High-Sulfur Fuel Oil (HSFO) while remaining compliant with emission limits.

Understanding SOx Emissions and Regulatory Framework

SOx emissions result from the combustion of fuels containing sulfur. Marine fuel oils, particularly HFO, can contain sulfur levels as high as 3.5%. When burned, this sulfur is released into the atmosphere as sulfur dioxide (SO₂), causing environmental and health problems. To mitigate these effects, the IMO introduced a global sulfur cap of 0.5% m/m (mass by mass) on marine fuels from January 1, 2020. Ships operating in Emission Control Areas (ECAs), such as the Baltic Sea, North Sea, and North American coastlines, face an even stricter limit of 0.1% m/m. Compliance can be achieved by using low-sulfur fuel or installing SOx scrubbers.

How SOx Scrubbers Work

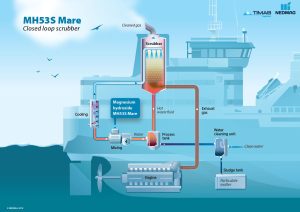

SOx scrubbers are onboard systems designed to clean ship exhaust gases before they are released into the atmosphere. The process involves spraying a liquid, usually seawater or a specific alkaline solution, into the exhaust stream. This liquid reacts with sulfur dioxide, neutralizing it and converting it into less harmful substances such as sulfate or calcium sulfate, which can be safely disposed of.

The scrubbing process typically involves three stages:

- Gas Cooling: The exhaust gas is cooled using a water spray to optimize the chemical reaction.

- Gas Washing: A chemical reaction occurs between the SO₂ in the exhaust gas and the scrubbing liquid.

- Emission Discharge: Cleaned exhaust gases are released into the atmosphere, while the residual wash water is treated to remove harmful components before discharge.

Types of SOx Scrubbers

SOx scrubbers can be classified into three main types based on their operational modes:

- Open-Loop Scrubbers: These systems use seawater as the scrubbing liquid, taking advantage of its natural alkalinity. The used water is discharged back into the sea after treatment, making this type suitable for ships operating in open ocean waters.

- Closed-Loop Scrubbers: These systems use a chemical solution, often sodium hydroxide, in a closed water cycle. The treated water is continuously recirculated, making closed-loop scrubbers ideal for areas with stricter discharge regulations, such as ports and ECAs.

- Hybrid Scrubbers: Combining the features of both open and closed-loop systems, hybrid scrubbers offer operational flexibility. Ships can switch between modes depending on geographic and regulatory requirements.

–

Case Study: MV AIDAprima – Pioneering Green Technologies

The cruise ship MV AIDAprima is a notable example of SOx scrubber implementation. Fitted with a state-of-the-art hybrid scrubber system, the ship can operate efficiently in various environmental conditions. The system has enabled the vessel to reduce sulfur emissions by up to 90% while also lowering particulate matter emissions by 70%. This technology aligns with the ship’s broader sustainability goals, showcasing how modern ships can balance commercial viability with environmental responsibility.

–

Operational Considerations and Challenges

While SOx scrubbers are effective, their installation and operation present several challenges:

– Capital and Installation Costs: The initial investment for scrubber systems can range from $1 million to $5 million, depending on the ship’s size and system complexity.

– Maintenance and Downtime: Scrubbers require regular maintenance, including descaling and water treatment system checks. Maintenance costs can be significant, impacting operational budgets.

– Regulatory Compliance: Ships must comply with a wide range of national and regional environmental regulations, which can sometimes differ from International Maritime Organization (IMO) standards. This complexity requires constant monitoring and administrative oversight to ensure adherence to all applicable rules. Recent updates from the IMO, particularly through resolutions MEPC.259(68) and MEPC.340(77), have introduced specific limits for discharges of certain substances from ships. These regulations aim to minimize the environmental impact of ship operations and ensure the protection of marine ecosystems. Below is a detailed explanation of the key parameters regulated under these resolutions: pH, PAH (Polycyclic Aromatic Hydrocarbons), turbidity, and nitrates:

- pH

pH is a measure of the acidity or alkalinity of a substance, and its regulation is critical to prevent harm to marine life. Discharges with extreme pH levels can disrupt the delicate balance of marine ecosystems, affecting aquatic organisms and water quality. Regulation: Under MEPC.340(77), the minimum pH level for discharges from ships is set at 6.5. This ensures that the discharged water is neither too acidic nor too alkaline, maintaining a neutral to slightly acidic range that is safe for marine environments. The measurement must be taken at the discharge point to ensure compliance.

- PAH (Polycyclic Aromatic Hydrocarbons)

PAHs are a group of organic compounds that are often byproducts of combustion processes. They are highly toxic and persistent in the environment, posing significant risks to marine life and human health. Regulation: MEPC.340(77) introduces a maximum limit of 50 µg/L (micrograms per liter) for PAHs, measured as phenanthrene equivalent. This strict limit aims to reduce the release of these harmful substances into the marine environment, ensuring that ship operations do not contribute to the accumulation of toxic pollutants.

- Turbidity

Turbidity refers to the cloudiness or haziness of water caused by suspended particles. High turbidity can block sunlight, affecting photosynthesis in marine plants and disrupting aquatic habitats. Regulation: MEPC.340(77) sets a limit for turbidity at 25 FNU/NTU (Formazin Nephelometric Units/Nephelometric Turbidity Units) above the inlet levels. This regulation ensures that discharges do not significantly increase the turbidity of surrounding waters, thereby protecting marine ecosystems from the adverse effects of suspended particles.

- Nitrates

Nitrates are compounds that can enter marine environments through various sources, including ship discharges. Excessive nitrate levels can lead to eutrophication, a process that depletes oxygen in water and harms marine life. Regulation: MEPC.340(77) requires ships to achieve a 12% removal of nitrogen oxides (NOx) from exhaust gases to comply with nitrate discharge limits. This regulation is part of broader efforts to reduce the environmental impact of ship emissions and prevent the harmful effects of nitrate pollution on marine ecosystems.

– Environmental Concerns: Open-loop scrubbers have faced criticism due to potential marine pollution from wash water discharge. Some ports and coastal regions have banned their use, prompting operators to adopt closed-loop or hybrid systems. The IMO has been addressing these concerns by discussing regulations on the discharge of wash water from scrubbers, emphasizing the need for compliance with environmental protection standards.

These challenges highlight the need for ship operators to stay informed about evolving regulations while managing operational costs effectively.

Future of SOx Scrubbing Technologies

The maritime industry is continually evolving toward cleaner and more efficient technologies. In the future, SOx scrubbers may become more compact, cost-effective, and environmentally friendly through advancements in material science and engineering. Research is underway to develop alternative systems such as dry scrubbers and exhaust gas recirculation (EGR) technologies. Additionally, shipping companies are exploring zero-emission fuels such as hydrogen, ammonia, and methanol. While these fuels offer long-term solutions, SOx scrubbers remain a critical technology for transitioning the existing global fleet toward cleaner operations.

SOx scrubbers have proven to be a viable solution for reducing sulfur emissions in the maritime sector. They enable ships to comply with stringent international regulations while maintaining operational flexibility. Despite the challenges associated with cost, maintenance, and environmental concerns, scrubbers represent a key step in the industry’s broader sustainability journey. As shipping continues to adapt to environmental demands, the integration of innovative technologies like SOx scrubbers will play a pivotal role in shaping a cleaner, greener future for global maritime transport.