Marine propulsion refers to the system or mechanism used to generate thrust for moving watercraft through water. Although smaller boats still use paddles and sails, modern ships typically rely on mechanical systems that include an electric motor or internal combustion engine powering a propeller, or alternatively, an impeller in pump-jets. The field of marine engineering involves the design process of marine propulsion systems.

Marine propulsion has evolved over time, beginning with human-powered paddles and oars, and later, sails. Rowed galleys, some equipped with sail, played an important role in early human seafaring and warfare. The first advanced mechanical means of marine propulsion was the marine steam engine, which was introduced in the early 19th century. However, during the 20th century, it was replaced by two-stroke or four-stroke diesel engines, outboard motors, and gas turbine engines that were faster. In the 1950s, marine nuclear reactors were developed to produce steam to propel warships and icebreakers, but commercial application failed to gain popularity. In recent years, development of liquefied natural gas (LNG) fueled engines has gained recognition for their low emissions and cost advantages. Stirling engines, which are quieter and run smoother, propel small submarines in order to minimize noise levels, but their design is not used in civilian marine applications due to lower total efficiency compared to internal combustion engines or power turbines. Electric motors using battery packs have been used for propulsion on submarines and electric boats, and have been proposed for energy-efficient propulsion.

Ship propulsion systems are a vital aspect of any marine vessel, and there are several different types of propulsion systems used in ships today. In this article, we will discuss four types of ship propulsion systems: diesel engines, gas turbines, steam turbines, electric motors, and waterjets.

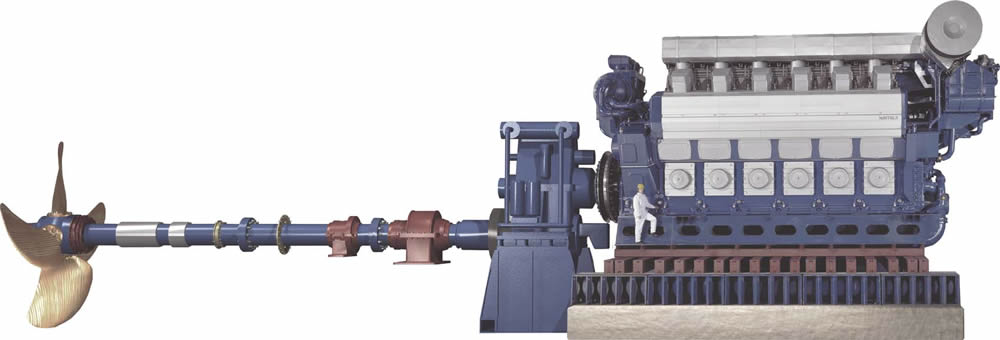

Diesel Engines:

Diesel engines are the most common type of propulsion system used in ships today. They are reliable, efficient, and have a long lifespan. Diesel engines are used in both commercial and military vessels, including cargo ships, tankers, and naval vessels. They work by using compressed air to ignite fuel oil in a combustion chamber. The resulting high-pressure gas is used to drive the engine’s pistons, which turn a crankshaft and ultimately drive the ship’s propeller.

Gas Turbines:

Gas turbines are commonly used in high-speed ships, such as naval vessels and passenger ferries. They provide high power output and are lightweight and compact, making them ideal for use in smaller vessels. Gas turbines work by compressing air and mixing it with fuel, which is then ignited in a combustion chamber. The resulting high-temperature gas is then used to drive the engine’s turbine blades, which turn a shaft and ultimately drive the ship’s propeller.

Steam Turbines:

Steam turbines were once the primary form of propulsion in large ships, but they have been largely replaced by diesel engines. However, steam turbines are still used in some niche applications, such as nuclear-powered vessels. Steam turbines work by heating water to produce steam, which is then used to drive the engine’s turbine blades. The resulting rotary motion is then used to drive the ship’s propeller.

Electric Motors:

Electric motors are used in some vessels, particularly those that require high maneuverability or low noise levels. They are often used in hybrid propulsion systems, which combine diesel engines and electric motors to provide more efficient operation. Electric motors work by using electrical energy to produce a magnetic field, which then causes the motor’s rotor to turn. The resulting rotary motion is then used to drive the ship’s propeller.

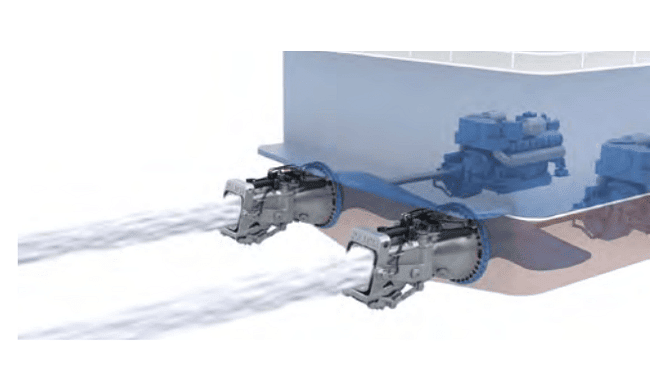

Waterjets:

Waterjets use a high-pressure jet of water to propel the vessel forward. They are commonly used in high-speed boats, such as patrol boats and rescue craft. Waterjets work by using a pump to force water through a nozzle, creating a high-speed jet of water that propels the vessel forward.

There are ship propulsion under development like FuelCell Propulsion, Solar propulsion, Biodiesel Fuel Propulsion, Methanol Propulsions,or Hydrogen Propulsion, however up to 2023 they are not commercialized on a large scale.

Ship propulsion systems are an essential component of any marine vessel, and there are several different types of propulsion systems used in ships today. Each system has its advantages and disadvantages, and the choice of propulsion system will depend on the specific needs and requirements of the vessel. In addition to the type of propulsion system used, other factors that can affect a ship’s speed and maneuverability include the size and shape of the propeller, the number of propellers, and the way in which the vessel is controlled and steered. Overall, ship propulsion systems are critical to the performance and efficiency of all types of marine vessels.

Prepared by MaritimEducation team.