The International Convention for the Prevention of Pollution from Ships, MARPOL, is a key international marine environmental convention aimed at minimizing pollution of the oceans and seas from ships. This includes pollution from oil, chemicals, garbage, sewage, and air emissions.

The MARPOL (International Convention for the Prevention of Pollution from Ships) Convention represents a pivotal piece of international maritime legislation focused on minimizing pollution caused by ships. Among its six annexes, MARPOL Annex I, titled Regulations for the Prevention of Pollution by Oil, is especially critical. This annex provides regulatory guidance on oil pollution prevention and control, addressing both operational discharges and accidental oil spills. Here’s a breakdown of the key aspects of Annex I, tailored for ship cadets, maritime students, and engineers.

Discover how MARPOL Annex I is transforming marine environmental protection. Learn about regulations on oil pollution, onboard systems, enforcement challenges, and innovations in this complete guide.

Why MARPOL Annex I Matters in Modern Maritime Operations

From oil tanker spills to routine bilge discharge, the ocean has borne the consequences of poor waste management. In response to such hazards, the International Maritime Organization (IMO) introduced MARPOL Annex I — the first and one of the most vital annexes of the International Convention for the Prevention of Pollution from Ships (MARPOL).

Since its enforcement in October 1983, Annex I has not only shaped environmental compliance for oil-carrying vessels, but also become a symbol of the maritime sector’s commitment to sustainable operations. It now applies to over 99% of the world’s merchant fleet, regulating everything from oil discharge criteria to pollution prevention equipment.

Evolution and Scope of MARPOL Annex I

MARPOL Annex I originally emerged from growing global concern after disasters like the Torrey Canyon oil spill in 1967 and Exxon Valdez in 1989, both of which shocked the public and exposed the lack of regulatory frameworks. Annex I applies to all ships over 400 gross tonnage, and oil tankers above 150 GT, requiring both types to carry approved equipment and meet strict discharge standards. As of 2025, more than 160 IMO member states have ratified the convention.

Its core objectives include:

- Preventing operational discharge of oil into the sea

- Minimizing risks from accidental spills

- Mandating construction and design features (e.g., double hulls)

- Enforcing record-keeping via the Oil Record Book

Key Regulations and Technical Requirements

Oil Discharge Criteria

1. Discharge of Oily Water from the Engine Room (All Ships)

Oily water in the engine room originates from machinery space bilges, containing oil residues from fuel, lubricating oils, and other machinery operations.

Key Requirements:

✅ Oil Content Limit: The discharged effluent must not exceed 15 parts per million (ppm) of oil.

✅ Oil Filtering Equipment:

- Ships ≥ 400 gross tonnage (GT) must have an approved Oily Water Separator (OWS) or an equivalent system.

- The OWS must include a 15 ppm alarm and an automatic stopping device to prevent excessive discharge.

✅ Discharge Monitoring & Control:

- Ships ≥ 10,000 GT must be fitted with an Oil Discharge Monitoring and Control System (ODMCS) to ensure compliance.

- Ships ≥ 400 GT but <10,000 GT need only an OWS with an oil content meter.

✅ Discharge Conditions:

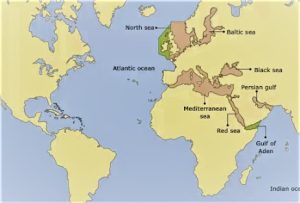

- Prohibited inside special areas (e.g., Mediterranean, Baltic, Black Sea, Red Sea, Antarctic, etc.) unless equipped with an approved ODMCS and outside the special area.

- The ship must be en route (i.e., actively moving) while discharging.

- Discharge must take place through an approved OWS, ensuring oil content does not exceed 15 ppm.

✅ Record Keeping: All discharges must be recorded in the Oil Record Book (Part I).

Prohibited Discharges:

❌ Discharge is NOT allowed if the ship is within a special area (unless exempted).

❌ Discharge is NOT allowed if the ship is not en route (not moving).

2. Discharge of Oily Water from Cargo Tank Cleaning (Tankers)

Oily water from cargo tank cleaning is generated during tank washing operations and may contain residues of oil cargo.

The discharge of such oily water is regulated under MARPOL Annex I, Regulation 34.

Key Requirements:

✅ Oil Content Limit: The discharged effluent must not exceed 15 ppm of oil.

✅ Tanker Location: The tanker must be outside special areas to discharge oily water from cargo tank cleaning.

✅ Tanker Operation (“En Route” Requirement): The tanker must be en route (moving) during discharge.

✅ Instantaneous Discharge Rate: The maximum allowable discharge rate is 30 liters per nautical mile.

✅ Total Quantity of Oil Discharged: The total quantity of oil discharged must not exceed:

- 1/30,000 of the total cargo volume for tankers built on or after December 31, 2015.

- 1/15,000 of the total cargo volume for tankers built before that date.

✅ Oil Discharge Monitoring and Control System (ODMCS): Tankers ≥ 150 GT must be equipped with an Oil Discharge Monitoring and Control System (ODMCS) to ensure compliance.

✅ Record Keeping: All discharges must be recorded in the Oil Record Book (Part II).

Prohibited Discharges:

❌ Discharge is NOT allowed in special areas.

❌ Discharge is NOT allowed if the tanker is not en route.

❌ Discharge is NOT allowed if the oil content exceeds 15 ppm.

Oil Record Book (ORB)

The Oil Record Book is a critical element of compliance under Annex I. It is a document used to record all oil-related operations on board, including loading, discharging, bunkering, and ballast water cleaning. Entries in the ORB provide a comprehensive record of the ship’s operations and are subject to inspection by authorities.

Maintaining an accurate and up-to-date ORB is essential for cadets and engineers alike, as it not only ensures compliance but also serves as a primary document during inspections by port authorities or during investigations into suspected pollution incidents.

Crude Oil Washing (COW) and Tank Cleaning on Tankers

Crude Oil Washing is a method used by oil tankers during cargo discharge to clean the cargo tanks using crude oil itself, under controlled pressure and temperature. Required on tankers above 20,000 DWT under MARPOL Annex I, COW improves tank cleanliness, reduces sludge buildup, and maximizes cargo recovery while limiting the use of water for washing. Following COW, water may be used for final tank cleaning, and all washings must be properly discharged through the slop tank and monitored to ensure environmental compliance.

Slop Tank

Slop tanks are designated for collecting oil-contaminated water from tank washing, ballasting, and other cargo operations. They play a key role in MARPOL Annex I compliance by preventing overboard discharge of oily residues. All mixtures stored in slop tanks must be processed through approved systems like the ODME (Oil Discharge Monitoring Equipment) before any legal discharge. Slop tanks must also be included in the ship’s Oil Record Book, with all operations accurately logged for PSC inspections.

ODME (Oil Discharge Monitoring Equipment) Operation

Oil Discharge Monitoring Equipment (ODME) is a vital MARPOL Annex I system installed on tankers to monitor and control the discharge of oily water mixtures from slop tanks or cargo operations. ODME automatically measures oil content, calculates discharge rates, and ensures compliance with discharge limits (e.g., 30 liters per nautical mile, and not more than 1/15,000th of the total cargo for tankers). If limits are exceeded, the system shuts off discharge automatically. Crew members must be trained to operate and maintain the ODME to ensure lawful discharges and avoid PSC violations.

Special Areas with Strict Standards

Annex I designates specific areas as Special Areas where stricter regulations on oil discharges apply due to the vulnerability of these regions to pollution. These areas include the Mediterranean Sea, the Baltic Sea, the Black Sea, the Red Sea, and the “Persian Gulf Area” among others. Ships operating in these regions are prohibited from discharging any oil or oily mixtures into the sea, regardless of their concentration levels.

Understanding the Special Areas is crucial for maritime students and cadets, as these zones require strict operational discipline and adherence to preventive measures to protect sensitive marine ecosystems.

Segregated Ballast Tanks (SBT)

Segregated Ballast Tanks are dedicated tanks used to carry ballast water that is completely separated from cargo oil tanks and their associated piping systems. Under MARPOL Annex I, oil tankers of 20,000 DWT and above must be equipped with SBTs to prevent contamination of seawater during ballasting and deballasting operations. By physically isolating ballast from oil residues, SBTs significantly reduce the risk of marine pollution and simplify compliance with discharge regulations.

Sludge Tank and International Sludge Shore Connection

Sludge tanks are used to store oily residues (sludge) generated from the purification of fuel and lubricating oils. MARPOL Annex I mandates proper containment and disposal of sludge to prevent illegal discharge into the sea. Ships must also be equipped with a standard International Shore Connection for sludge disposal at port reception facilities. This allows sludge to be transferred ashore safely and in compliance with regulations, minimizing onboard accumulation and the temptation for unlawful disposal.

Oil Pollution Emergency Plan (SOPEP)

All oil tankers of 150 GT and above, and other ships of 400 GT and above, must carry an approved SOPEP. This plan outlines procedures for:

- Notifying authorities

- Containing oil spills

- Coordinating cleanup with Port State Control (PSC)

Many SOPEPs are now digitized and integrated into fleet management systems.

A Shipboard Oil Pollution Emergency Plan (SOPEP) is required for every vessel, designed to prepare the crew for swift and effective responses to oil spills. Cadets and junior officers should familiarize themselves with the SOPEP, as knowing the emergency procedures is critical to managing any accidental oil discharges.

Double Hull Requirements

Following oil spill catastrophes, MARPOL mandated double hulls for tankers — a structural feature that creates a buffer zone between cargo oil tanks and the sea. As of 2015, all new tankers must comply with this design (IMO, Regulation 19 of MARPOL Annex I).

Port State Control (PSC) and MARPOL Annex I Compliance

Port State Control (PSC) inspections are a critical enforcement mechanism for MARPOL Annex I, ensuring ships adhere to international pollution prevention standards. During these inspections, PSC officers check the condition and operation of oil discharge equipment (such as Oily Water Separators and Oil Discharge Monitoring Equipment), examine the Oil Record Book (ORB), and evaluate the crew’s knowledge of procedures related to pollution control.

Failing a PSC inspection can lead to serious consequences—including vessel detention, financial penalties, and even criminal charges—especially in cases involving falsified records or deliberate bypassing of pollution control systems. For example, in 2021, a Greek shipping company was fined $2.7 million in the U.S. for tampering with ORB entries.

PSC enforcement is conducted under regional regimes such as the Paris MoU and Tokyo MoU. In 2023, over 7% of detained ships in Paris MoU ports had deficiencies related to the ORB, underlining the importance of thorough compliance. Some ports have enhanced surveillance capabilities, deploying drones and satellite technology to detect illegal oil discharges, particularly in ecologically sensitive regions like the Baltic Sea and the Great Barrier Reef.

Compliance extends beyond hardware; it requires a well-trained and vigilant crew. Engineers, officers, and cadets must understand operational procedures, participate in regular training and emergency drills, and be familiar with tools like the Shipboard Oil Pollution Emergency Plan (SOPEP). For cadets, active involvement in safety briefings and onboard maintenance enhances their practical grasp of Annex I obligations and PSC expectations.

–

Real-World Cases and Lessons Learned

The Prestige Disaster (2002)

The Prestige oil tanker sank off the coast of Spain, releasing over 63,000 tons of oil. The lack of a double hull and poor international coordination worsened the damage. The disaster accelerated EU regulations and influenced Annex I amendments, particularly on structural integrity.

Voluntary Reporting and Transparency

Many large shipping companies such as Maersk and NYK Line now publish environmental performance reports detailing MARPOL Annex I compliance, often verified by classification societies like DNV or Bureau Veritas.

–

Innovations and Future Outlook

Digital Compliance Systems: Modern vessels are equipped with real-time discharge monitoring, automated record-keeping, and blockchain-based logbooks. These technologies improve transparency and reduce human error.

Bio-Based and Eco-Friendly Lubricants: To minimize oil pollution, some ships are switching to biodegradable lubricants. This aligns with EU Ecolabel criteria and reduces environmental harm in the event of leakage.

Integration with ESG Reporting: Compliance with MARPOL Annex I is becoming a part of broader Environmental, Social, and Governance (ESG) strategies. Investors now monitor environmental performance, increasing the pressure on maritime operators to avoid pollution violations.

–

Frequently Asked Questions (FAQ)

What is the main objective of MARPOL Annex I?

To prevent both accidental and operational oil pollution from ships by enforcing construction, equipment, and discharge regulations.

What is the 15 ppm rule in MARPOL Annex I?

It prohibits discharge of oily water unless oil content is less than 15 parts per million, monitored using approved filtering equipment.

What is the SOPEP manual and who needs it?

A Shipboard Oil Pollution Emergency Plan required for tankers ≥150 GT and other ships ≥400 GT, outlining spill response procedures.

Can ships ever legally discharge oil into the sea?

Yes, but only under strict conditions: <15 ppm oil content, operational filtering system, and distance >12 nautical miles from land.

What are the penalties for violating MARPOL Annex I?

Penalties include heavy fines, vessel detention, and criminal charges depending on the jurisdiction and severity of the offense.

–

Conclusion

MARPOL Annex I is more than just a regulatory framework — it’s a lifeline for the ocean. From the engine room of a cargo ship to the halls of IMO headquarters, it reflects a collective commitment to protecting marine ecosystems.

As technology advances and environmental standards rise, the shipping industry must remain agile, transparent, and responsible. The sea has carried human trade and dreams for millennia. Now, with Annex I, we are learning how to carry that responsibility in return.

–

References

- International Maritime Organization. (2024). MARPOL Consolidated Edition.

- UNCTAD. (2024). Review of Maritime Transport. https://unctad.org

- Marine Pollution Bulletin. https://www.sciencedirect.com/journal/marine-pollution-bulletin

- Paris MoU Annual Report 2023. https://www.parismou.org

- DNV Maritime Environmental Reports. https://www.dnv.com

- Bureau Veritas. MARPOL Services. https://marine-offshore.bureauveritas.com

- Alfa Laval. Oily Water Treatment Systems. https://www.alfalaval.com

- Wärtsilä. Environmental Solutions. https://www.wartsila.com

- Lloyd’s List Intelligence. https://lloydslist.maritimeintelligence.informa.com

- Marine Insight. https://www.marineinsight.com

- U.S. Department of Justice. Maritime Pollution Prosecutions. https://www.justice.gov/enrd/maritime-pollution

–

✅ MULTIPLE CHOICE QUESTIONS

1. What is the primary focus of MARPOL Annex I?

A. Prevention of air pollution from ships

B. Regulation of garbage disposal at sea

C. Prevention of pollution by oil

D. Regulation of sewage discharges

Correct Answer: C. Prevention of pollution by oil

2. According to MARPOL Annex I, what is the maximum oil content allowed in discharged bilge water from the engine room?

A. 30 ppm

B. 10 ppm

C. 20 ppm

D. 15 ppm

Correct Answer: D. 15 ppm

3. Which equipment is mandatory for ships ≥ 400 GT to prevent oil pollution from bilge water?

A. Sewage Treatment Plant

B. Oil Discharge Monitoring Equipment

C. Oily Water Separator (OWS) with 15 ppm alarm

D. Garbage Compactor

Correct Answer: C. Oily Water Separator (OWS) with 15 ppm alarm

4. For tankers built after December 31, 2015, what is the maximum allowed total oil discharge from tank cleaning operations?

A. 1/10,000 of total cargo

B. 1/15,000 of total cargo

C. 1/30,000 of total cargo

D. 1/50,000 of total cargo

Correct Answer: C. 1/30,000 of total cargo

5. What document must all oil discharges be recorded in as per MARPOL Annex I?

A. Logbook of the Chief Engineer

B. Engine Room Log

C. Oil Record Book (Part I or II)

D. MARPOL Compliance Register

Correct Answer: C. Oil Record Book (Part I or II)

6. What is the purpose of a SOPEP (Shipboard Oil Pollution Emergency Plan)?

A. To document crew schedules

B. To coordinate oil spill response procedures

C. To monitor air pollution

D. To report ballast water usage

Correct Answer: B. To coordinate oil spill response procedures

7. Which of the following is a designated Special Area under MARPOL Annex I?

A. Arctic Ocean

B. North Sea

C. Mediterranean Sea

D. Indian Ocean

Correct Answer: C. Mediterranean Sea

8. What is the maximum instantaneous discharge rate allowed for oily water from tank cleaning operations?

A. 20 liters per nautical mile

B. 40 liters per nautical mile

C. 15 liters per nautical mile

D. 30 liters per nautical mile

Correct Answer: D. 30 liters per nautical mile

9. Which ships are required to have an Oil Discharge Monitoring and Control System (ODMCS)?

A. All ships

B. Tankers ≥ 150 GT

C. Fishing vessels

D. Yachts

Correct Answer: B. Tankers ≥ 150 GT

10. What is the role of Port State Control (PSC) with respect to MARPOL Annex I?

A. To collect voyage data

B. To conduct audits of IMO headquarters

C. To inspect vessels for compliance with pollution prevention measures

D. To manage ship crew sign-on procedures

Correct Answer: C. To inspect vessels for compliance with pollution prevention measures

✅ TRUE/FALSE QUESTIONS

1. MARPOL Annex I only applies to oil tankers.

Explanation: It applies to all ships, although some provisions are specific to tankers.

2. Oil discharges are prohibited in Special Areas, regardless of oil concentration.

3. The ship must be en route (moving) while discharging oily water under Regulation 15 and 34.

4. SOPEP is a voluntary guideline and not required on ships.

Explanation: A SOPEP is mandatory under MARPOL Annex I.

5. The Oil Record Book only records accidental oil discharges.

Explanation: It records both operational and accidental discharges, bunkering, loading, tank cleaning, etc.

6. An OWS must shut down automatically if the oil content exceeds 15 ppm.

7. MARPOL Annex I includes regulations for garbage and sewage discharges.

Explanation: Garbage and sewage are covered under different annexes (Annex V and IV, respectively).

8. Tankers built before December 31, 2015, are allowed to discharge more oil than newer tankers.

Explanation: Their limit is 1/15,000 of total cargo, versus 1/30,000 for newer vessels.

9. PSC officers can inspect the Oil Record Book during port inspections.

10. Regular training on OWS, ODMCS, and SOPEP is crucial for MARPOL compliance.