Steering gear is a critical component of a ship’s safety and navigational control system. It ensures that a vessel can change direction efficiently and respond quickly to commands from the bridge. Any failure in the steering system can pose serious risks, especially in congested waterways or during adverse weather conditions. The SOLAS Convention (International Convention for the Safety of Life at Sea), governed by the International Maritime Organization (IMO), sets out detailed regulations for steering gear systems on all seagoing vessels to enhance maritime safety and reduce the risk of steering failure-related accidents.

In this article, we’ll cover:

-

The types of steering gear used on ships

-

Technical specifications and performance criteria

-

SOLAS requirements for redundancy, power, testing, and alarms

-

Periodic testing and survey obligations

-

Key amendments and updates in SOLAS

-

Compliance challenges and inspection tips

Let’s begin by understanding the fundamental components and types of steering gear systems.

Types of Steering Gear Systems on Ships

There are several types of steering gear systems in use today, depending on vessel type, size, and operational requirements:

1. Ram-Type Steering Gear

This system consists of hydraulic rams connected to a tiller or quadrant, which turns the rudder. It’s reliable and commonly used on large commercial ships.

2. Rotary Vane Steering Gear

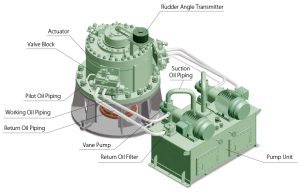

A compact system where hydraulic pressure is applied to vanes inside a housing to turn the rudder stock. It’s efficient, quiet, and space-saving, often used on modern vessels.

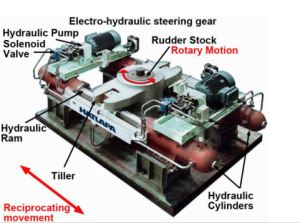

3. Electro-Hydraulic Steering Gear

This type combines electric motors and hydraulic pumps to generate force. The electrical system controls the hydraulic mechanism, offering precise and responsive control.

4. Mechanical Steering Gear

Primarily found on smaller vessels, this system involves direct mechanical linkage (cables, rods) between the steering wheel and rudder.

Understanding these systems helps contextualize the requirements outlined by SOLAS.

Ram Type Steering Gear of Ship, Credit: https://www.merchantnavydecoded.com/steering-gear-system-on-ship/

ROTARY VANE STEERING GEAR, Credit: https://dieselship.com/marine-technical-articles/marine-engineering-knowledge-general/rotary-vane-steering-gear/

Core Functions of Steering Gear as per SOLAS

According to Regulation 29 of SOLAS Chapter II-1, the steering gear system must be capable of:

-

Turning the rudder from 35° on one side to 30° on the other in not more than 28 seconds at maximum service speed.

-

Operating with redundant power sources in case the main source fails.

-

Providing continuous control from the bridge under normal conditions.

-

Quickly switching to emergency steering mode if needed.

Let’s now dive deeper into the SOLAS Convention requirements.

–

SOLAS Regulations for Steering Gear (Chapter II-1, Regulation 29–30)

1. General Requirements (Regulation 29)

SOLAS requires that every ship of 100 gross tons and above, and all passenger ships regardless of tonnage, must have a main and an auxiliary steering gear system. The main gear must:

-

Turn the rudder through the required angles within 28 seconds

-

Operate at maximum ahead service speed

-

Be capable of continuous operation and control from the bridge

2. Auxiliary Steering Gear Requirements

The auxiliary steering gear must:

-

Be independent of the main system

-

Be capable of steering the ship at navigable speeds (not necessarily full service speed)

-

Operate from a secondary control position if the main bridge controls fail

SOLAS requires that the auxiliary gear must be brought into operation in no more than 45 seconds after a failure of the main gear.

3. Power Systems and Redundancy

-

Steering gear must be powered by at least two independent power sources.

-

If the main power fails, the ship should not lose steering capability.

-

Each system must have automatic changeover features where applicable.

-

Passenger ships must have two completely independent steering systems.

Hydraulic Steering Gear Requirements

Key SOLAS Provisions for Hydraulic Systems:

-

Hydraulic power units (HPUs) must include two independent pumps, each capable of operating the gear.

-

Hydraulic fluid reservoirs must be sufficient for one complete operation cycle plus reserve.

-

Systems must include emergency hand pumps or manual overrides if power fails.

-

Isolation valves must allow separation of main and auxiliary systems without draining fluid.

Control and Alarm Systems

Bridge Control Requirements:

-

All vessels must have remote control from the bridge.

-

The control must be fail-safe, with audible and visual alarms on failure.

-

A rudder angle indicator must be installed and clearly visible.

-

Any failure in the power unit, control system, or hydraulic pressure must trigger alarms both in the engine control room and on the bridge.

Emergency Steering Arrangements

SOLAS emphasizes that emergency steering systems must be:

-

Located outside the machinery space (often in the steering gear room)

-

Operable by a local manual control

-

Provided with communication systems between bridge and steering position

-

Capable of rudder position feedback

Emergency drills must be conducted regularly to ensure crew competency in switching to emergency steering.

Read more here: https://maritimeducation.com/emergency-steering-gear-drill-on-ships-a-lifesaving-routine-explained/

Periodic Testing Requirements Under SOLAS

To ensure reliability, SOLAS mandates regular testing of all steering systems.

Monthly Testing (SOLAS Regulation 26.3.2):

-

Testing of main and auxiliary systems

-

Bridge steering gear controls

-

Emergency power supply

-

Communication systems

-

Verification of alarm indicators

Pre-departure Checks (SOLAS Regulation 26.3.1):

Before leaving port, the following must be verified:

-

Steering gear power supply

-

Operation of remote control systems

-

Emergency steering arrangements

-

Operation of rudder angle indicators

Annual Surveys:

Flag State or Classification Society inspectors verify:

-

Full compliance with SOLAS design criteria

-

Operational capability under loaded conditions

-

Redundancy and control features

-

Hydraulic system integrity and fluid levels

-

Logbooks for testing and maintenance records

Amendments and Notable Changes to SOLAS Steering Gear Rules

Several IMO amendments over the years have updated steering gear standards, including:

1. IMO Resolution MSC.137(76):

-

Introduced stricter testing procedures and documentation requirements.

2. Amendments in SOLAS 2000 and 2004:

-

Emphasized automatic isolation of failed components.

-

Required rudder order indicators on the bridge and control rooms.

3. SOLAS 2020 Updates:

-

New requirements for electrically-propelled steering systems.

-

Enhanced monitoring features with sensor diagnostics for early detection of failure.

Keeping up with these changes is critical for shipowners and operators to ensure compliance and avoid PSC detentions.

Classification Society Rules and Integration with SOLAS

In addition to SOLAS, classification societies like DNV, Lloyd’s Register, and ABS enforce their own steering gear design and performance standards, which often exceed minimum SOLAS requirements.

These include:

-

Load calculations for rudder torque

-

Detailed failure mode analysis

-

Endurance and shock testing for military vessels

-

Integration with Dynamic Positioning (DP) systems in offshore ships

Compliance with both SOLAS and class rules is essential for vessel certification.

Challenges in Compliance and Common PSC Deficiencies

Failure to comply with SOLAS steering gear requirements is one of the most common Port State Control (PSC) deficiencies. Common issues include:

-

Inoperative alarms or rudder indicators

-

Leaking hydraulic lines

-

Inadequate testing records or incomplete logbooks

-

Crew unfamiliarity with emergency procedures

-

Delayed response in switching to auxiliary power

To mitigate these risks, ship operators should implement:

-

A structured Preventive Maintenance System (PMS)

-

Crew training and drills on manual and emergency steering

-

Daily checks on fluid levels, alarms, and system response

Best Practices for Compliance and Safety

To ensure both SOLAS compliance and operational safety, adopt the following best practices:

-

Log all monthly and pre-departure tests in the engine and bridge logbooks.

-

Train deck and engine officers in emergency procedures.

-

Conduct joint drills between bridge and steering gear room teams.

-

Inspect and replace hydraulic oil filters regularly.

-

Use condition monitoring sensors to detect anomalies early.

-

Follow class-approved maintenance schedules and inspection routines.

-

Keep manual override instructions posted in the steering gear compartment.

Future Trends in Steering Gear Technology

With advancements in automation and ship digitization, steering gear systems are becoming smarter and more integrated.

Key trends include:

-

Condition-based maintenance (CBM) using IoT sensors

-

AI-driven diagnostics for predictive alerts

-

Digital twins for steering gear simulation and fault modeling

-

Integration with autonomous ship navigation systems

-

Adoption of green hydraulic fluids for eco-compliance

These technologies aim to reduce downtime, improve responsiveness, and enhance overall safety at sea.

Conclusion

The steering gear is not just a mechanical component—it’s a vital safety system governed by strict international regulations under the SOLAS Convention. SOLAS regulations ensure that vessels are equipped with robust, redundant, and responsive steering systems capable of operating under various conditions, including emergency situations. Shipowners, engineers, and navigational officers must thoroughly understand and implement these standards to protect crew, cargo, and the marine environment.

By maintaining high levels of compliance, conducting regular testing, and embracing modern technology, the maritime industry can continue to minimize steering gear failures—one of the most critical risks in vessel navigation.

Emergency Steering Gear Drill on Ships: A Lifesaving Routine Explained

thank you

Hi there everyone, it’s my first pay a quick visit at this

website, and post is in fact fruitful in support of me, keep up posting these types of content.

Hi mates, how is everything, and what you want to say concerning this article, in my view

its really awesome designed for me.

My partner and I stumbled over here from a different page and thought I may as well check things out.

I like what I see so i am just following you. Look forward to checking out your web page again.

you are in point of fact a good webmaster. The web site loading

speed is amazing. It kind of feels that you are doing any distinctive trick.

Also, The contents are masterwork. you have done

a excellent process in this matter!

Hello! I could have sworn I’ve been to your blog before but after looking at a few of

the posts I realized it’s new to me. Nonetheless, I’m definitely delighted I discovered it and I’ll be bookmarking it and checking back frequently!

I am not sure where you are getting your information, but

great topic. I needs to spend some time learning more or

understanding more. Thanks for wonderful info I was looking for this info

for my mission.

It is perfect time to make some plans for the

future and it is time to be happy. I have read this post and if I could I want to suggest you some interesting things

or tips. Perhaps you could write next articles referring to this article.

I wish to read even more things about it!

Every weekend i used to go to see this site, as i wish for enjoyment, since this this web site conations in fact nice funny

material too.

This is a topic which is near to my heart… Many thanks!

Exactly where are your contact details though?

What’s up everyone, it’s my first visit at this web page, and post is actually fruitful for me, keep up posting

these posts.

Hi there, I discovered your website by means of Google whilst searching for a

similar subject, your website came up, it seems great. I have bookmarked it in my google

bookmarks.

Hello there, simply became alert to your weblog thru Google, and found that it’s truly informative.

I am going to watch out for brussels. I’ll appreciate when you continue this in future.

Many people shall be benefited out of your writing. Cheers!

Good day! This post couldn’t be written any better! Reading this post reminds me of my previous room mate! He always kept talking about this. I will forward this post to him. Fairly certain he will have a good read. Thank you for sharing!

Thank you for some other informative web site. Where else may just I get that type of

info written in such an ideal method? I’ve a mission that I am

simply now running on, and I have been at the look out for such info.

If you are going for best contents like me, simply pay a visit this site daily as it provides quality contents, thanks

Hello to all, for the reason that I am really eager of reading

this web site’s post to be updated on a regular basis.

It consists of nice data.

I was wondering if you ever thought of changing the structure of your blog?

Its very well written; I love what youve got to say. But maybe you could a little more in the

way of content so people could connect with it better.

Youve got an awful lot of text for only having one or 2 pictures.

Maybe you could space it out better?

Hi there, yeah this piece of writing is genuinely good and I have learned lot of

things from it concerning blogging. thanks.

My brother recommended I may like this web site. He used

to be totally right. This publish actually made my day.

You cann’t imagine simply how much time I had spent for this information! Thank you!

you’re in reality a just right webmaster. The web site loading pace is incredible.

It seems that you’re doing any unique trick.

Moreover, The contents are masterwork. you have done a excellent activity on this topic!

Thanks very nice blog!

I used to be able to find good info from your articles.

Simply desire to say your article is as astounding. The clearness for your publish is just excellent and i

could think you’re an expert in this subject. Well with your permission allow

me to clutch your RSS feed to keep updated with imminent post.

Thank you one million and please continue the gratifying work.

Attractive section of content. I just stumbled upon your

web site and in accession capital to assert that I acquire actually enjoyed account your blog posts.

Any way I will be subscribing to your augment and even I achievement you access consistently rapidly.

Hi there, I enjoy reading through your article. I wanted to write a little comment to support you.

Quality posts is the secret to invite the visitors to visit the web site, that’s

what this web site is providing.

This page really has all the information and facts I needed about this subject and didn’t know who to ask.

Very nice article. I certainly appreciate this site. Keep it up!

Your way of explaining everything in this article

is actually fastidious, all can effortlessly be aware of it, Thanks a lot.

It’s really a cool and helpful piece of information. I’m happy

that you just shared this helpful information with us.

Please stay us informed like this. Thank you for sharing.

I read this piece of writing completely regarding the resemblance of most recent and preceding

technologies, it’s awesome article.