Navigational safety is paramount in maritime operations, with steering gear systems being the helm of maneuverability for vessels. Steering gear systems, sophisticated in design and critical in function, are integral to the course and stability of a ship. Despite rigorous safety standards and periodic maintenance, these systems can encounter an array of problems, leading to operational inefficiencies or severe maritime accidents.

Incidents and Implications of Steering Gear Failures

Maritime history is replete with incidents attributable to steering gear failures. A notable instance involved a vessel that, while under pilotage, experienced a critical failure in its steering gear system. Despite manual inputs, the rudder failed to respond, leading to the grounding of the ship at a significant speed. Such failures underscore the susceptibility of ships to grave risks, emphasizing the damage potential to the vessel, crew safety, and the environment.

Common Steering Gear System Issues

Despite the stringent policies against leakages, such as those enforced by port state controls, steering gear systems are prone to several recurrent issues, eight of which are particularly common:

- Oil Leakages: One of the most frequent problems arises from oil leakages due to worn seals or gaskets, requiring immediate attention to prevent environmental pollution and penalties.

- Mismatched Rudder Angles: Discrepancies between the commanded and actual rudder angles, often stemming from improper adjustments of control mechanisms, need precise recalibration.

- Unsatisfactory Steering Performance: Subpar steering operations can lead to increased fuel consumption and travel delays, frequently caused by malfunctioning valves or control levers.

- Excessive Noise and Vibrations: Such symptoms usually indicate air entrapment in the system, necessitating venting procedures and checks on oil supply tank valves.

- Elevated Oil Temperatures: High temperatures can thin hydraulic oil, compromising system efficiency. This issue often relates to low oil levels, highlighting the need for functional alarms and regular replenishment.

- Rudder Angle Limitations: Deviations from the specified rudder angle range, as mandated by SOLAS, may result from faulty limit switches, which require timely repair or adjustment.

- Remote Control Failures: For circumstances where remote steering becomes unresponsive, backup hydraulic systems or control pathways must be readily activatable.

- Linkage Disconnections: Rare but critical failures, such as the detachment of linkages between tillers and rudder angle transmitters, necessitate routine inspections to prevent loss of rudder indicator input.

Regulatory Requirements and Testing Procedures

Recognizing the critical role of steering gears, regulations from international bodies and classification societies have established comprehensive requirements:

- Dual steering gear systems are mandated to ensure operational redundancy.

- Main steering gears must showcase the capability of rapid rudder movement within specific degrees and time frames.

- Auxiliary steering gears should be quickly deployable, with performance standards defined for various scenarios.

- Steering gear power units must be bridge-operable, featuring alarms and automatic restart functions upon power restoration.

- Regular operational checks, including emergency power supply tests and steering drills, are to be conducted to maintain readiness and functional integrity.

Steering Gear Types and Designs

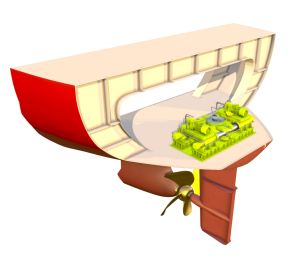

Steering gear systems on ships are vital for maneuvering and directing the course of a vessel.

Ship Rotary Vane Steering Gears

There are several types of steering gear systems, each with its own mechanism and application:

- Hydraulic Steering Gears: The most common type, utilizing hydraulic pressure to move the rudder. These systems can be further classified into:

- Ram-Type Steering Gears: Have one or more hydraulic rams directly connected to the rudder stock.

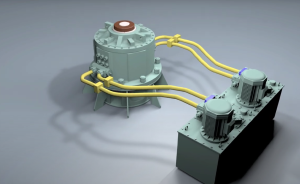

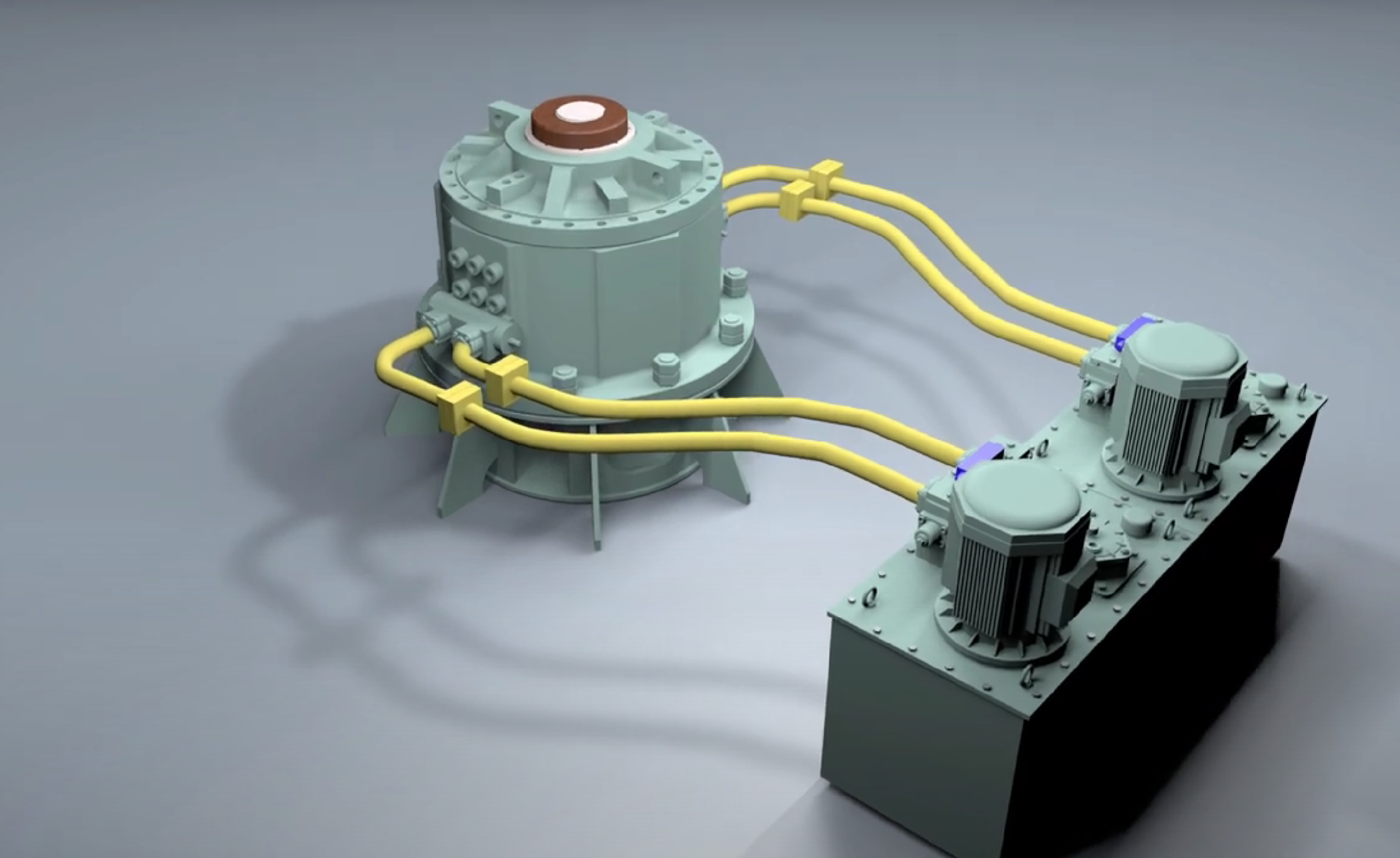

- Rotary Vane Steering Gears: Use a rotor in a cycloidal cam to convert hydraulic pressure into rotational motion of the rudder stock.

- Electro-Hydraulic Steering Gears: Combine electrical power with hydraulic systems to steer the ship. They offer finer control and are efficient in power consumption.

- Electric Steering Gears: Use electric motors to turn the rudder. These are less common and typically used on smaller ships or as auxiliary steering systems.

- Manual Steering Gears: Operated by hand, these systems are typically found on very small vessels or as backup systems in case of failure of the primary steering gear.

- Pneumatic Steering Gears: Utilize compressed air to actuate the rudder movement, but are not commonly used due to the high energy requirement.

Each system has its own maintenance needs, response times, and operational complexities, and the choice of steering gear system will depend on ship size, type, and operational requirements.

In conclusion, the efficient operation and diligent maintenance of ship steering gear systems are non-negotiable aspects of maritime safety. While common problems persist, adherence to regulatory requirements, routine checks, and a robust understanding of steering gear mechanisms serve as the bulwarks against potential failures, safeguarding vessels on their voyages across the global seas.

hello

thank you, that`s great