Environmental Performance Evaluation (EPE) is a structured and systematic approach used to assess, monitor, and improve the environmental performance of organizations, including shipping companies. The maritime industry, as a significant contributor to global trade, faces increasing pressure to minimize its environmental footprint. EPE facilitates compliance with international regulations, enhances sustainability efforts, and optimizes operational efficiency by measuring key environmental indicators.

Concept of Environmental Performance Evaluation(EPE)

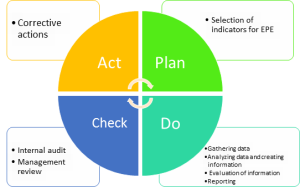

Environmental Performance Evaluation (EPE) is an ongoing and dynamic process that integrates environmental monitoring, assessment, and improvement strategies into organizational practices. It follows a structured approach, often aligned with the Plan-Do-Check-Act (PDCA) cycle, to ensure continuous improvement and compliance with environmental standards. Below is a refined explanation of the EPE process, aligned with the attached image:

1. Plan

- Establish Environmental Objectives: The process begins with setting clear, quantifiable, and strategic environmental objectives. These objectives are tailored to mitigate environmental impacts, such as reducing greenhouse gas (GHG) emissions, minimizing hazardous waste, and preventing marine pollution.

- Selection of Indicators for EPE: Key performance indicators (KPIs) are selected to measure progress toward these objectives. Examples include fuel consumption rates, emissions levels, and waste management metrics.

2. Do

- Gathering Data: This stage involves the systematic collection of environmental data based on the selected indicators. Data may include fuel usage, emissions, waste generation, and compliance with regulatory standards.

- Implementation of Actions: Organizations execute planned actions, such as adopting energy-efficient technologies, optimizing operational processes, and training staff on environmental best practices.

3. Check

- Analyzing Data and Creating Information: The collected data is analyzed to evaluate performance against predefined objectives, industry benchmarks, and regulatory requirements. This analysis helps identify trends, discrepancies, and areas for improvement.

- Internal Audit: Regular internal audits are conducted to verify compliance with environmental policies and assess the effectiveness of implemented measures.

- Evaluation of Information: The analyzed data is evaluated to determine the success of current strategies and identify gaps or opportunities for enhancement.

4. Act

- Corrective Actions: Based on the evaluation, corrective actions are implemented to address identified shortcomings. This may involve revising policies, improving operational practices, or investing in new technologies.

- Management Review: Senior management reviews the findings and approves necessary changes to ensure alignment with organizational goals and regulatory requirements.

- Reporting: Comprehensive reports are prepared and shared with stakeholders, including regulatory bodies, investors, customers, and the public. Effective reporting ensures transparency, accountability, and stakeholder confidence.

The EPE process is iterative, with a focus on continuous improvement. Organizations refine their environmental policies, adopt best practices, and integrate innovative technologies to reduce emissions, waste, and other environmental impacts. This ensures that environmental performance is consistently optimized, reinforcing long-term sustainability goals and strengthening compliance with international regulations.

The EPE process aligns seamlessly with the PDCA cycle as depicted in the below image:

- Plan: Setting objectives and selecting indicators.

- Do: Gathering data and implementing actions.

- Check: Analyzing data, conducting internal audits, and evaluating information.

- Act: Taking corrective actions, conducting management reviews, and reporting.

The EPE process, when aligned with the PDCA cycle, provides a robust framework for shipping companies to monitor, assess, and improve their environmental performance. By following this structured approach, organizations can achieve regulatory compliance, reduce operational costs, enhance their reputation, and contribute to global sustainability efforts. Continuous improvement ensures that environmental performance remains a priority, driving innovation and long-term success in the maritime industry.

Main Definitions

Understanding key terminologies associated with EPE is essential for its effective implementation in the maritime industry:

- Environmental Indicator: A quantifiable measure used to evaluate an organization’s environmental performance, such as CO2 emissions per nautical mile, energy consumption per voyage, or fuel efficiency.

- Environmental Impact: The direct or indirect consequences of maritime operations on the environment, including air pollution, marine biodiversity disruption, and ecosystem degradation.

- Environmental Management System (EMS): A structured framework that enables organizations to systematically manage environmental responsibilities, ensuring continuous improvement in environmental performance.

- Carbon Footprint: The total greenhouse gas emissions produced directly and indirectly by an entity, expressed in CO2 equivalents, providing a benchmark for sustainability efforts.

- Life Cycle Assessment (LCA): A comprehensive methodology used to assess the environmental impacts of a product, service, or process from its inception to disposal, ensuring sustainable decision-making.

Key Components of Environmental Performance Evaluation in the Maritime Industry

Shipping companies utilize EPE to assess and improve various environmental aspects of their operations. The key components include:

Fuel Efficiency: Regular monitoring and optimization of fuel consumption through energy-saving technologies and operational best practices, reducing overall emissions and operational costs.

Emissions Monitoring: Measuring and reporting emissions of carbon dioxide (CO2), sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter (PM) to comply with the International Maritime Organization’s (IMO) MARPOL Annex VI and European Union environmental regulations.

Waste Management: Developing effective waste management policies aligned with the International Convention for the Prevention of Pollution from Ships (MARPOL), ensuring proper treatment, disposal, and recycling of ship-generated waste.

Ballast Water Management: Adhering to the Ballast Water Management (BWM) Convention to prevent the transfer of invasive aquatic species, safeguarding marine biodiversity.

Energy Efficiency Design Index (EEDI): A regulatory metric applied to new ships to ensure compliance with energy efficiency standards, encouraging the adoption of innovative ship design solutions.

–

Benefits of Environmental Performance Evaluation in Shipping

Environmental Performance Evaluation is a vital instrument for shipping companies aiming to achieve sustainability objectives, regulatory compliance, and operational efficiency. By systematically monitoring and improving environmental performance, maritime operators can actively contribute to environmental conservation and global climate change mitigation efforts. The integration of robust EPE frameworks within the maritime sector ensures that shipping companies can balance economic growth with environmental responsibility, paving the way for a more sustainable maritime industry.

1(b),2(c),3(b),4(c),5(b),6(b),7(b)

Here are 5 multiple-choice questions based on the article about Environmental Performance Evaluation (EPE) in the maritime industry, suitable for ship cadets:

:

What is the primary purpose of Environmental Performance Evaluation (EPE) in the maritime industry?

(a) To increase operational costs for shipping companies

(b) To assess, monitor, and improve the environmental performance of maritime organizations

(c) To create more paperwork for maritime administrators

(d) To slow down global trade

:

Which of the following is a key component of the Environmental Performance Evaluation (EPE) process?

(a) Ignoring waste management policies

(b) Decreasing fuel efficiency to save on technology costs

(c) Emissions Monitoring

(d) Promoting the transfer of invasive aquatic species

:

Which international convention is directly related to effective waste management policies in the maritime industry, as part of EPE?

(a) International Convention for the Prevention of Safety of Life at Sea (SOLAS)

(b) International Convention for the Prevention of Pollution from Ships (MARPOL)

(c) Ballast Water Management (BWM) Convention

(d) Standards of Training, Certification and Watchkeeping for Seafarers (STCW)

:

What does the acronym PDCA stand for in the context of Environmental Performance Evaluation (EPE)?

(a) Plan, Direct, Control, Assess

(b) Prevent, Detect, Correct, Analyze

(c) Plan, Do, Check, Act

(d) Perform, Document, Certify, Approve

:

Which of the following is an example of an environmental indicator used in Environmental Performance Evaluation (EPE)?

(a) Number of crew members on board

(b) CO2 emissions per nautical mile

(c) Size of the vessel’s cargo hold

(d) Speed of the ship in knots

:

What is one of the key benefits of adhering to international maritime environmental regulations?

(a) Increased fuel consumption

(b) Reduced risk of legal penalties

(c) Higher operational costs

(d) Decreased corporate reputation

:

How does enhancing fuel efficiency contribute to shipping companies?

(a) It increases waste production

(b) It leads to significant cost savings

(c) It reduces the need for technological advancement

(d) It weakens the company’s reputation