Cargo Tank Washing and Slop Tanks: The Need for ODME

Tanker ships play a critical role in global trade, transporting vast quantities of crude oil and refined petroleum products across the oceans. To ensure operational efficiency and prevent contamination between cargoes, tankers must undergo cargo tank washing after unloading their cargo. This process removes residual oil and sediments from the tanks, preparing them for the next voyage or for carrying a different grade of oil.

However, cargo tank washing generates large volumes of oil-contaminated water, which must be handled carefully to prevent marine pollution. This contaminated water is typically collected in a slop tank, a designated onboard storage tank where oil residues are allowed to separate from water over time. The clean water portion can then be discharged overboard, provided it meets international environmental standards.

To regulate and monitor this discharge, tanker ships are required to use Oil Discharge Monitoring Equipment (ODME)—an automated system that ensures the oil content in discharged water does not exceed permissible limits. ODME plays a crucial role in preventing pollution, ensuring compliance with international regulations such as MARPOL Annex I, and promoting sustainable maritime practices.

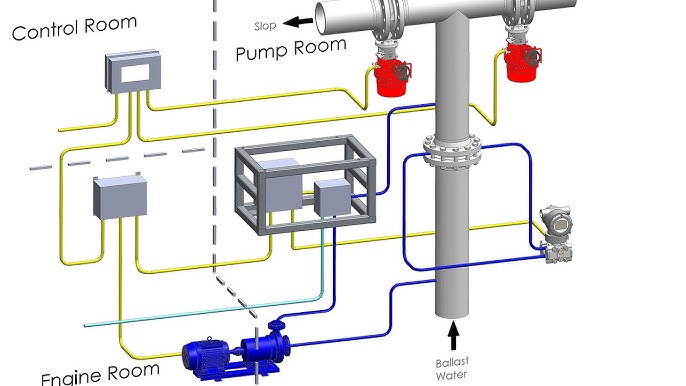

Positions of slope tanks, pump room, and engine room on a typical tanker ship, credit: DOI:10.4043/31639-MS

What is Oil Discharge Monitoring Equipment (ODME)?

Oil Discharge Monitoring Equipment is an automated system installed on tanker ships to monitor and control the discharge of oil-contaminated water from cargo tanks. It ensures that the oil content in the discharged water does not exceed the limits set by international regulations, such as those by the International Maritime Organization (IMO).

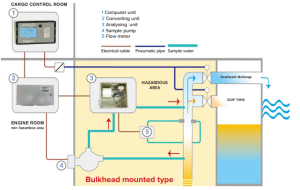

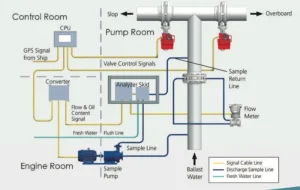

Key Components of ODME:

-

Computing Unit (Computer unit – 1) – Processes data from the Oil Content Meter (OCM) and the flow rate indicator to calculate the total oil discharge.

-

Recording Device (Part of Computer unit – 1) – Logs all discharge operations for compliance and auditing purposes.

- Control Panel (Converting unit – 2) – Displays real-time data and allows operators to control the system.

- Oil Content Meter (Analysing unit – 3 & Sample pump-4) – Measures the oil concentration in the water being discharged.

- Flow Rate Indicator (Flow meter – 5) – Monitors the rate at which water is discharged.

How Does ODME Work?

- Sampling: Water from the cargo tanks is continuously sampled as it is discharged.

- Analysis: The Oil Content Meter analyzes the oil concentration in the sampled water.

- Calculation: The computing unit calculates the total oil discharge based on the flow rate and oil concentration.

- Control: If the oil concentration exceeds permissible limits, the system automatically stops the discharge or diverts it to a slop tank for further treatment.

- Recording: All data is recorded for regulatory compliance and inspection purposes.

Regulatory Framework: IMO and MARPOL Annex I

The International Maritime Organization (IMO) has established strict regulations to prevent marine pollution from ships. The primary regulation governing oil discharge is MARPOL Annex I, which sets limits on the oil content in discharged water and mandates the use of ODME on tanker ships.

Key Provisions of MARPOL Annex I:

- Oil Content Limit: The oil content in discharged water must not exceed 15 parts per million (ppm).

- Discharge Rate: The discharge rate must not exceed 30 liters per nautical mile.

- Total Discharge Volume: The total quantity of oil discharged during a ballast voyage must not exceed 1/30,000 of the total cargo capacity.

- ODME Requirement: Tankers of 150 gross tonnage and above must be equipped with an approved ODME system.

ISSGOT Guidelines: The International Safety Guide for Oil Tankers and Terminals (ISSGOT) provides additional operational guidelines for the safe and environmentally responsible use of ODME. It emphasizes proper calibration, maintenance, and crew training to ensure the system’s accuracy and reliability.

Importance of ODME in Modern Shipping

- Environmental Protection: ODME helps prevent oil pollution by ensuring that only water with minimal oil content is discharged into the sea.

- Regulatory Compliance: It enables tanker operators to comply with IMO regulations, avoiding penalties and reputational damage.

- Operational Efficiency: By automating the monitoring process, ODME reduces the risk of human error and ensures efficient discharge operations.

- Data Logging: The recording feature provides a transparent and auditable record of discharge operations, which is crucial during inspections.

Challenges and Best Practices

Challenges:

System Calibration: Regular calibration is essential to maintain the accuracy of the Oil Discharge Monitoring Equipment (ODME). Without proper calibration, the system may provide incorrect readings, leading to non-compliance with regulations or unnecessary operational disruptions.

Maintenance: ODME systems require routine maintenance to prevent malfunctions. Neglecting maintenance can result in system failures, which may compromise the ship’s ability to monitor and control oil discharges effectively.

Crew Training: Operators must be adequately trained to use the ODME system effectively. A lack of proper training can lead to operational errors, misinterpretation of data, or failure to respond appropriately to system alerts.

Best Practices:

Conduct Regular Calibration and Maintenance: Follow the manufacturer’s guidelines for calibration and maintenance to ensure the ODME system operates accurately and reliably. Regular checks and servicing can prevent unexpected issues and extend the system’s lifespan.

Train Crew Members: Provide comprehensive training to crew members on the proper operation and troubleshooting of the ODME system. Well-trained operators can handle the system more efficiently and respond effectively to any operational challenges.

Keep Detailed Records: Maintain detailed records of all discharge operations, including calibration, maintenance, and discharge data. These records are crucial for regulatory compliance and can be invaluable during inspections or audits.

Conclusion

Oil Discharge Monitoring Equipment is an indispensable tool for tanker ships, ensuring compliance with international regulations and protecting marine ecosystems. By understanding its functionality, regulatory requirements, and best practices, maritime professionals can contribute to safer and more sustainable shipping operations. As the industry continues to evolve, advancements in ODME technology will further enhance its effectiveness in preventing oil pollution.

For more information on ODME and related regulations, refer to the IMO MARPOL Annex I and the ISSGOT guidelines.