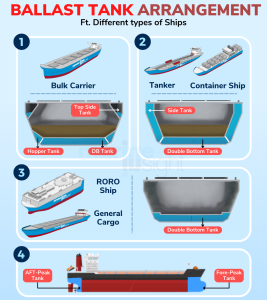

In the maritime industry, maintaining a ship’s stability and seaworthiness is crucial, especially for tankers transporting oil and hazardous cargo. One essential feature in modern tankers is the Segregated Ballast Tank (SBT) system, a regulatory requirement under MARPOL to prevent pollution and enhance vessel safety.

This article explores what segregated ballast tanks are, how they work, their importance in environmental protection, and key differences between other ballast systems.

What is a Segregated Ballast Tank (SBT)?

A segregated ballast tank is a tank dedicated exclusively to carrying ballast water. These tanks are completely separated from cargo oil and fuel oil systems and are permanently used for ballast operations. Unlike older designs where ballast water was stored in cargo tanks (increasing the risk of oil contamination), SBTs eliminate cross-contamination, ensuring cleaner ballast discharge.

Key Features:

- Separated from cargo and fuel systems.

- Reduces the risk of oil pollution.

- Required by MARPOL Annex I for oil tankers of 20,000 deadweight tonnage (DWT) and above.

- Improves ship stability during ballast voyages.

Why are Segregated Ballast Tanks Important?

The implementation of SBTs is primarily driven by environmental protection regulations. Key reasons include:

A. Prevention of Marine Pollution: Before MARPOL regulations, ships used cargo tanks for ballast operations, leading to oily ballast discharge into the sea. SBTs ensure ballast water remains free of oil contamination.

B. Compliance with MARPOL Annex I: According to Regulation 18 of MARPOL Annex I, oil tankers of certain sizes must have segregated ballast tanks to reduce the risk of oil pollution.

C. Improved Ship Stability: During ballast conditions (when a ship is travelling without cargo), SBTs allow proper weight distribution, reducing excessive hull stress and improving safety in rough seas.

Credit: Marine Insight

Differences Between Clean Ballast, Dedicated Ballast, and Segregated Ballast Tanks

There are different types of ballast tank systems used in shipping. Here’s how they compare:

| Type of Ballast Tank | Definition | Pollution Risk | MARPOL Requirement |

|---|---|---|---|

| Segregated Ballast Tank (SBT) | Separate from cargo tanks, exclusively used for ballast. | No risk of oil pollution. | Mandatory for oil tankers ≥ 20,000 DWT (Reg. 18, MARPOL Annex I). |

| Clean Ballast Tank (CBT) | Cargo tanks used for ballast but must be cleaned before discharge. | Medium risk if not cleaned properly. | Allowed in some older vessels. |

| Dedicated Clean Ballast Tank (DCBT) | Cargo tanks specifically assigned for ballast but still part of cargo system. | Lower risk compared to CBT but not as safe as SBT. | Was used before full SBT implementation. |

🔹 Key takeaway: SBTs are the safest and most environmentally friendly solution.

MARPOL Regulations and Segregated Ballast Tanks

The requirement for segregated ballast tanks is part of a broader framework under MARPOL Annex I to prevent oil pollution from ships. Specific regulatory provisions include:

- Regulation 16: Segregation of oil and water ballast.

- Regulation 18: Mandatory SBTs for tankers ≥ 20,000 DWT.

- Regulation 19: Double hull requirements in conjunction with SBTs for extra protection.

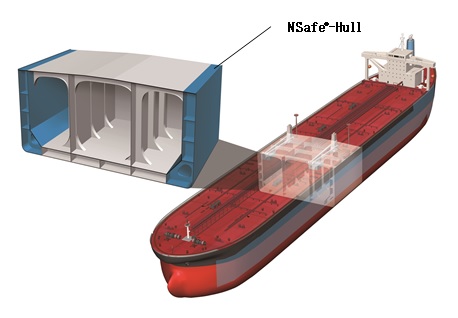

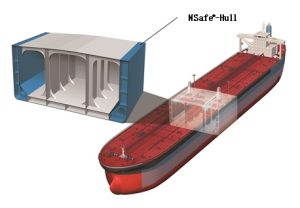

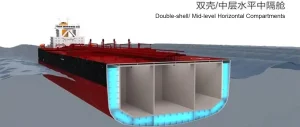

SBTs, along with double-hull designs, ensure minimal environmental risks in case of structural damage.

How Do Segregated Ballast Tanks Work?

In practice, segregated ballast tanks operate through a dedicated ballast system that includes:

- Ballast Pumps: Used to load and discharge ballast water.

- Piping System: Independent from cargo and fuel systems.

- Valves and Sensors: Monitor ballast levels and prevent mixing.

During a ballast voyage (when the ship is traveling without cargo), water is pumped into the segregated tanks to maintain stability. When loading cargo, the ballast water is discharged in compliance with environmental regulations.

Lightship Condition and Ballast

A ship in a lightship condition, which refers to a state where the vessel is carrying minimal or no cargo, must carefully manage its ballast to ensure stability, safety, and optimal performance. Ballast is essential in this condition to counteract the lack of cargo weight, which can otherwise lead to excessive trim (the difference in draft between the bow and stern) and uneven stress distribution across the hull. Proper ballasting is crucial to maintain the ship’s structural integrity and operational efficiency.

Role of Segregated Ballast Tanks (SBTs)

Segregated Ballast Tanks (SBTs) are specifically designed to carry only ballast water, separate from cargo tanks. They play a critical role in maintaining the ship’s stability and safety, particularly in lightship conditions. Here’s how SBTs contribute:

- Reduce Free Surface Effect: The free surface effect occurs when liquid in partially filled tanks shifts with the ship’s movement, causing instability. In lightship conditions, the risk of excessive rolling due to this effect is higher. SBTs help mitigate this by ensuring ballast water is properly contained, reducing the free surface effect and enhancing the ship’s stability.

- Improve Hydrodynamics: Proper ballasting ensures the ship maintains an optimal draft and trim, which improves its hydrodynamic efficiency. This reduces water resistance, leading to lower fuel consumption and improved operational efficiency. In lightship conditions, where the ship is naturally lighter, SBTs help achieve the necessary weight distribution to maintain hydrodynamic performance.

- Enhance Ship Safety: In heavy weather or rough seas, a ship in lightship condition is more susceptible to instability due to its reduced weight. SBTs provide the necessary ballast to lower the ship’s center of gravity, improving its ability to withstand harsh conditions. This enhances overall safety by reducing the risk of capsizing or structural damage.

In summary, the use of SBTs in lightship conditions is vital for maintaining stability, improving fuel efficiency, and ensuring the safety of the vessel and its crew. Proper ballast management, particularly through SBTs, is a key operational practice in maritime operations.

Frequently Asked Questions

Q1: What is the main advantage of segregated ballast tanks?

👉 They prevent oil pollution by keeping ballast water separate from cargo oil and fuel oil.

Q2: Are segregated ballast tanks required on all ships?

👉 No. They are mainly required for oil tankers of 20,000 DWT and above, as per MARPOL regulations.

Q3: How do SBTs compare to clean ballast tanks?

👉 Clean ballast tanks (CBTs) require cleaning before discharge, whereas SBTs are separate from cargo and do not need additional cleaning, making them safer.

Q4: Do SBTs improve ship stability?

👉 Yes. By providing better weight distribution, they prevent excessive stress on the hull and improve performance in rough seas.

Conclusion

Segregated Ballast Tanks (SBTs) have revolutionized tanker safety and environmental protection. By ensuring ballast water remains free from oil contamination, they help ships comply with MARPOL Annex I while improving stability and operational efficiency.

As a maritime professional or student, understanding SBTs is essential for navigating modern tanker regulations and sustainability standards. With the industry’s push toward greener shipping, segregated ballast systems continue to play a crucial role in minimizing marine pollution.

🔹 Key Takeaway: If you are working on or managing a tanker, always ensure compliance with SBT requirements and understand their impact on ship operations and marine conservation.

Excellent blog right here! Also your site lots up very fast!

What web host are you the use of? Can I get your affiliate hyperlink to

your host? I want my site loaded up as quickly as yours lol