In maritime operations, maintaining the ship’s safety and stability during emergencies is paramount. One critical component designed for this purpose is the emergency bilge suction valve. This valve plays a crucial role in protecting the ship from flooding, particularly in the engine room or other critical compartments, when regular bilge pumps are overwhelmed, disabled, or unable to manage excess water. This article provides a detailed overview of the emergency bilge suction valve, its integration with the ship’s systems, and its operational considerations.

The Role of the Emergency Bilge Suction Valve

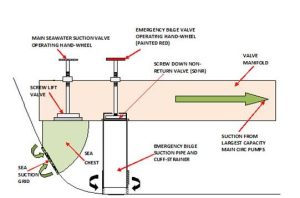

Contrary to common misconceptions, the emergency bilge suction valve is not connected to the ship’s normal bilge system. Instead, it is integrated into the main sea water system through the main sea water suction and discharge lines. This means that during an emergency, pumps normally used for seawater operations, such as sea water cooling pumps, fire pumps, or ballast pumps, can be used to evacuate water from the engine room or other flooded compartments if the emergency bilge suction valve is opened.

In simpler terms, the emergency bilge suction valve allows the ship to bypass the smaller bilge pumps, providing an alternative and more powerful method to remove large volumes of water quickly. The main goal of this valve is to ensure that critical systems in the engine room remain operational by prohibiting flooding.

Key characteristics of the emergency bilge suction valve include:

- High capacity: It is designed to handle much larger volumes of water than the regular bilge pumps.

- Direct Connection to Main Sea Water Systems: Unlike traditional bilge systems, the emergency bilge suction valve is connected to the main sea water suction line. It allows seawater pumps to take suction from the bilge or flooded compartment.

- Utilization of High-Capacity Pumps: In an emergency, pumps like sea water cooling pumps, fire pumps, and ballast pumps can be used to evacuate water from the engine room when the valve is opened. These pumps are typically designed for high-capacity flow, making them suitable for rapid dewatering operations.

- Emergency Flood Control: By opening the emergency bilge suction valve, the ship can prevent flooding of critical areas, maintaining engine room operations and overall ship stability. This is especially important in cases where main bilge pumps fail or are overwhelmed by excessive water ingress.

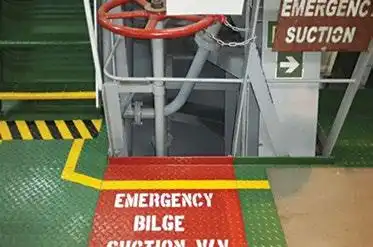

- Manual Operation and Accessibility: The valve is usually manually operated and is located in an easily accessible area within the engine room to ensure quick response in emergency scenarios.

–

Operational Considerations

Operating the emergency bilge suction valve requires careful consideration of the following factors:

- Regular Maintenance and Inspection: Since the emergency bilge suction valve is a key safety feature, it is crucial that it is regularly maintained and inspected. This ensures that the valve will function properly when needed.

- Coordination with Other Ship Systems: The activation of this valve involves rerouting suction for sea water pumps, which are critical for other functions such as engine cooling and fire-fighting. Therefore, care must be taken to ensure that these systems are not compromised during an emergency dewatering operation.

- Emergency Procedures: Crewmembers must be trained in the correct operation of the emergency bilge suction valve as part of their emergency response drills. Understanding when and how to deploy the valve is essential to prevent improper use, which could lead to further complications during an emergency.

–

Types of Ships and Their Emergency Bilge Suction Systems

The design, size, and operational details of the emergency bilge suction valve may vary depending on the type of ship. Below is an overview of how different types of vessels incorporate this critical component:

1. Cargo Ships

In cargo vessels, especially bulk carriers, significant volumes of water can accumulate in the holds due to cargo seepage or hull breaches. The emergency bilge suction valve in such ships is typically connected to high-capacity pumps capable of handling the larger volumes of water. In these vessels, the valve may be designed to handle water mixed with debris or cargo residue, requiring robust filters or strainers to prevent clogging.

2. Passenger Ships (Cruise Ships and Ferries)

Passenger ships have stringent safety protocols, and their bilge systems are designed to handle potential flooding from a wide array of sources, including damage to the hull. Emergency bilge suction valves in these ships are connected to auxiliary machinery or emergency pumps that can be operated remotely. Due to the large number of people on board, these valves are often part of a more complex emergency system designed to ensure rapid evacuation of water from critical areas such as the engine room, accommodations, and public areas.

3. Tanker Ships (Oil, Chemical, and LNG Carriers)

Tanker ships are highly specialized vessels designed to transport liquid cargo. These ships are designed to prevent the ingress of water into the cargo tanks, but water can still accumulate in the machinery spaces or ballast tanks. Emergency bilge suction valves on tanker ships must comply with strict environmental regulations, especially since accidental discharge of bilge water mixed with cargo residues can lead to severe pollution. These valves are typically connected to the ship’s segregated ballast system or dedicated pumps to ensure any discharge is controlled and environmentally compliant.

4. Naval Vessels

Naval ships are equipped with highly robust bilge and emergency systems due to their need to operate in combat situations. The emergency bilge suction valves on these ships are part of an integrated damage control system that includes sensors and remote operation capabilities. Naval ships also require redundancy, so there are often multiple emergency bilge suction valves located in various compartments to ensure quick action in case of damage from combat or other emergencies.

5. Fishing Vessels

Fishing vessels are more prone to water ingress due to their operational environment. These ships often operate in rough seas, where the risk of flooding from waves or hull breaches is higher. The emergency bilge suction valve in fishing vessels is often connected to a simple but high-capacity manual pump system, enabling quick response to emergencies even if power is lost.

–

Design and Operation of Emergency Bilge Suction Valves

The design and operation of the emergency bilge suction valve must meet international safety standards set by organizations such as the International Maritime Organization (IMO) and classification societies (e.g., Lloyd’s Register, DNV-GL). Below are some key design and operational considerations:

- Size and Capacity: The size of the emergency bilge suction valve and associated piping must be large enough to handle the maximum expected inflow of water. Typically, the valve is sized to allow for a suction rate that is significantly higher than the main bilge system.

- Location: The valve is usually located in the engine room, often at the lowest point, where water is most likely to accumulate. It is connected to a high-capacity pump or to an overboard discharge pipe.

- Activation: In many cases, the emergency bilge suction valve is manually operated to prevent accidental activation. However, modern vessels may have automated systems that activate the valve when certain conditions, such as excessive water levels, are met.

- Redundancy: Ships often have more than one emergency bilge suction valve, especially in larger vessels or those with multiple compartments. This ensures that, even if one valve fails, others can take over.

- Maintenance and Testing: Regular maintenance and testing of the emergency bilge suction valve are crucial. This includes checking for blockages, testing the operation of the valve and associated pumps, and ensuring the valve can be easily accessed during an emergency.

Regulatory Requirements

International maritime regulations, particularly SOLAS (Safety of Life at Sea), require that all ships have effective bilge systems, including emergency bilge suction capabilities. The emergency bilge suction valve must meet specific criteria, such as:

- Being easily accessible during an emergency.

- Capable of handling large volumes of water.

- Constructed from materials resistant to corrosion and erosion.

- Regularly inspected and maintained as part of the ship’s safety management system.

In addition to SOLAS Convention, classification societies also provide guidelines for the design, operation, and testing of emergency bilge suction systems, ensuring that they meet the required safety standards.

The emergency bilge suction valve is a crucial safety component in a ship’s bilge system. Its primary function is to ensure that the vessel can quickly evacuate large amounts of water in the event of flooding, thus preserving the ship’s stability and buoyancy. While the specifics of its design and operation may vary depending on the type of ship, the underlying principle remains the same: to provide an efficient and reliable means of water removal during emergencies.

Ensuring proper maintenance, adherence to regulatory standards, and regular crew training in its operation are essential to maximizing the effectiveness of the emergency bilge suction valve and ensuring the safety of the vessel and its crew in critical situations.

🚢 Want to learn more? For additional related information, we recommend reading the following article:

Emergency Bilge Suction Valve in Ships’ Engine Rooms: A Comprehensive Guide

Thanks for this technical post.