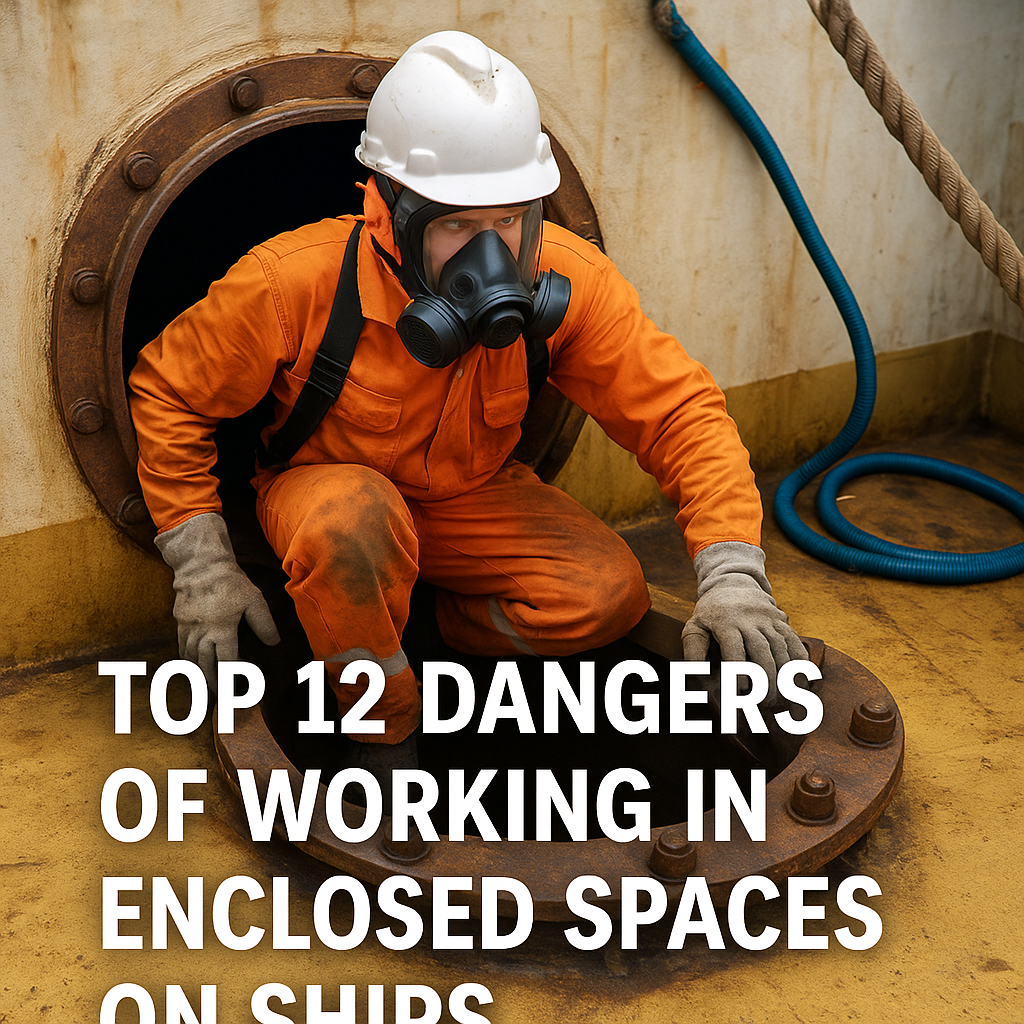

Enclosed spaces kill more seafarers than storms. This comprehensive guide explains the top 12 dangers of working in enclosed spaces on ships—from oxygen-deficient atmospheres and toxic gases to botched rescues—and shows the controls, drills, and technologies that actually save lives. Perfect for cadets, officers, HSE leads, and trainers.

On board, danger is often quiet. No breaking waves, no alarms—just a hatch, a tank, a void. Someone drops in to “take a quick look,” and within seconds they are on the deck, not breathing. Another crew mate rushes after them, and tragedy doubles. If you’ve sailed long enough, you’ve heard a version of this story. Sadly, it’s not folklore—it’s a recurring pattern.

“Enclosed space” is one of those phrases that hides sharp edges. Tanks, chain lockers, cofferdams, duct keels, double bottoms, void spaces, cargo holds under fumigation, even certain machinery rooms with poor ventilation—they can all become lethal, fast. The good news is that these deaths are preventable. The bad news is that preventability can breed complacency.

Why enclosed-space safety matters in modern maritime operations

Modern ships are larger, systems are more complex, and turnarounds are tighter. That raises the chance of encountering oxygen-deficient, toxic, or explosive atmospheres, and increases pressure to “get the job done quickly.” Meanwhile, multi-national crews and contractors may bring varied training backgrounds. All of this makes enclosed-space discipline a frontline issue for:

- Human life: Hundreds have died globally in the last two decades in enclosed spaces—often in clusters during attempted rescues. Estimates presented to the IMO indicate at least 1,000 fatalities between 2000 and 2024 on SOLAS-covered vessels and in ports worldwide.

- Compliance & reputation: Since 2015, enclosed space entry and rescue drills every two months are mandatory under SOLAS. Ships that treat this as a paper exercise are exposed—in audits, in Port State Control, and in courtrooms after incidents.

- Insurance & cost: Enclosed-space fatalities trigger long investigations, civil and criminal liabilities, and off-hire. P&I clubs repeatedly warn that most such deaths involve simple rule violations—no testing, no ventilation, no permit, and no breathing apparatus.

Bottom line: this is not a niche topic. It’s everyday seamanship—and it’s life or death.

What counts as an “enclosed space” aboard?

The IMO defines enclosed spaces by their limited openings, inadequate ventilation, and potential to create dangerous atmospheres. They include cargo tanks, ballast tanks, voids, cofferdams, duct keels, chain lockers, and cargo holds (especially when fumigated or with oxygen-depleting cargoes).

On tankers and terminals, the International Safety Guide for Oil Tankers and Terminals (ISGOTT) devotes an entire chapter to enclosed spaces, tying together permits to work, risk assessment, gas testing, LOTO, communications, and rescue readiness—not just for tankers, but as a model for any ship that treats safety as a system.

–

The top 12 dangers (and how they kill)

Each danger below includes what it is, why it’s lethal, and practical controls that meet or exceed recognized guidance. Think of these not as twelve separate problems, but as a stack—several may be present in the same space.

1) Oxygen deficiency

What it is: Air normally contains ~21% oxygen. Rusting (oxidation), biological activity, or displacement by other gases can drop O₂ without any smell or visible sign. At 16% you lose coordination; at 10% you collapse; at 6% you die in minutes.

Why it kills: The body gives little warning; victims “go quiet” fast and cannot self-rescue.

Controls that work:

Treat all enclosed spaces as unsafe until proven safe by testing—top, middle, bottom—before entry and continuously during work. Ventilate to well above 20.9% and maintain positive flow. Use calibrated multi-gas meters and log results on the permit.

2) Toxic gases (H₂S, CO, CO₂, VOCs)

What it is: Hydrogen sulphide from sewage tanks, carbon monoxide from combustion, carbon dioxide from biological decay, and volatile organic compounds from cargo residues.

Why it kills: Rapid respiratory paralysis or “silent” displacement. CO binds haemoglobin; victims appear “asleep.”

Controls that work:

Identify likely toxics in the risk assessment; test for them specifically. Use self-contained breathing apparatus (SCBA) when the atmosphere is uncertain or unstable, and re-test after breaks or temperature changes.

3) Explosive or flammable atmospheres

What it is: Flammable vapours from cargo residues, cleaning solvents, or off-gassing cargoes.

Why it kills: Ignition from static sparks, portable lights, or hot work can cause flash fires or explosions.

Controls that work:

Verify %LEL is 0 before entry or hot work. Use intrinsically safe lighting and radios, and follow ISM/ISGOTT hot-work controls with a fire watch and gas trending.

4) Fumigants and cargo treatment residues

What it is: Phosphine or other fumigants used in holds and containers.

Why it kills: Lethal at low ppm, often odourless and persistent.

Controls that work:

Treat post-fumigation holds or containers as enclosed spaces. Require formal gas-free certification and independent verification before entry. Lock access, post signage, and coordinate with port health and cargo interests.

5) Engulfment and entrapment (solids and slurries)

What it is: Grain, coal, ore fines, fishmeal, sludge, or mud that can collapse or liquefy, burying the entrant.

Why it kills: Suffocation in seconds; rescuers are pulled in.

Controls that work:

Adopt a zero-entry policy while cargo is free-to-move. Use poles, cameras, or drones where possible. If entry is essential, use retrieval systems, lifelines, and fixed anchor points, with a trained attendant on deck.

6) Falls from height and slips on ladders

What it is: Vertical access on corroded rungs, slick surfaces, poor lighting.

Why it kills: Short “just a look” entries cause severe trauma.

Controls that work:

Maintain three-point contact, ensure head and hand protection, and improve lighting. Replace or reject damaged rungs and secure temporary ladders properly.

7) Heat stress and thermal load

What it is: Tanks or spaces adjacent to machinery or heated cargoes.

Why it kills: Heat stroke can mimic hypoxia before anyone realizes it.

Controls that work:

Limit time inside, use buddy systems, cool-down breaks, and hydration. Cooling vests or airline respirators can offset SCBA thermal load.

8) Inadequate ventilation and dead zones

What it is: Short ventilation periods or blocked air paths behind stiffeners.

Why it kills: Gas pockets persist; conditions rebound quickly when fans stop.

Controls that work:

Force ventilation sized to the space volume; test top, middle, and bottom. Keep blowers running during work and exit immediately if ventilation stops.

9) Communication failure and loss of situational awareness

What it is: Dead radios, single-handed entry, “I’ll be two minutes.”

Why it kills: No call for help when symptoms start; rescuer follows instinct, not plan.

Controls that work:

Never enter alone. Post a trained attendant with continuous communication and a rescue plan. Conduct radio checks and agree on hand signals before entry.

10) Energy isolation failures (LOTO) and flooding

What it is: Unexpected pump starts, valve line-ups, or electrical activation.

Why it kills: Sudden flooding, moving machinery, or electric shock.

Controls that work:

Lock-out and tag-out pumps, breakers, and valves with verified line diagrams. Post clear “Do Not Operate” notices at all remote stations.

11) Contaminants generated by the job

What it is: Cleaning chemicals reacting with cargo residues, welding fumes, or solvent vapours created during work.

Why it kills: The space becomes toxic after entry; initial tests gave a false sense of security.

Controls that work:

Extend the risk assessment to process hazards. Adjust ventilation and gas-testing frequency during hot work or painting.

12) Botched rescue attempts

What it is: A colleague collapses; others rush in without BA. Multiple deaths follow.

Why it kills: Panic overrides training; rescuers become victims.

Controls that work:

Drill enclosed-space rescue realistically every two months as required by SOLAS. No rescue entry without breathing apparatus. Use retrieval equipment and call external SAR early.

–

Key technologies and developments driving safer entries

Modern practice blends people, process, and technology.

Smarter gas detection: Multi-gas meters with real-time logging and pumped sampling reduce blind spots. Continuous monitoring is becoming standard during longer jobs.

Ventilation with intent: ATEX-rated blowers, flexible ducting, and airflow calculations ensure genuine air exchange, not guesswork.

Digital permits to work: E-permits integrate risk assessments, gas readings, and photos, creating an auditable trail that discourages “tick-box” culture.

Rescue gear worth training with: Tripods, davits, retrieval blocks, and stretchers sized for manholes allow controlled extraction—if practiced.

Learning from data: P&I clubs and safety bodies synthesize case trends and push for structured training and contractor oversight.

ISGOTT 6th Edition: Widely adopted beyond tankers, it unifies the language of hazard identification, permits, and rescue planning, emphasizing human factors.

Challenges and solutions

Complacency and time pressure

Challenge: “It’s only five minutes.”

Solution: Build psychological “speed bumps” into your SMS: permit triggers, dual sign-off, and mandatory time-outs before breaking seals. Share real case studies in toolbox talks.

Multi-language, mixed-experience crews

Challenge: Instructions lost in translation.

Solution: Use bilingual permits, pictogram SOPs, and teach-back sessions where the entrant explains the plan to the officer.

Contractors and shore staff

Challenge: Everyone assumes someone else is in charge.

Solution: Designate one Officer-in-Charge for every entry who owns the permit, briefs the team, and verifies competence and BA training.

Inadequate rescue readiness

Challenge: BA sets are available but unused; retrieval gear in storage.

Solution: Conduct drills under realistic conditions—low light, tight deadlines, comms loss—and review timing and coordination.

Cargo-specific chemistry

Challenge: Self-heating or oxygen-consuming cargoes.

Solution: Integrate cargo data sheets and class guidance into risk assessments. When uncertain, assume danger and test more frequently.

Future outlook

Expect sharper global guidance from the IMO and classification societies, emphasizing structured risk assessment, improved training, and data-driven prevention. Industry groups such as InterManager and P&I associations are building global databases of fatalities to help target awareness campaigns.

Technological progress will continue: wearable gas detectors, continuous-feed air monitors, smart helmets with telemetry, and drone inspections for “zero entry” policies. Yet, even the best equipment cannot replace situational awareness, discipline, and respect for the unseen.

Frequently asked questions (FAQ)

What defines an enclosed space on a ship?

Any space with limited openings, poor ventilation, and potential for dangerous atmosphere—such as tanks, voids, cofferdams, and chain lockers.

How often are drills required?

Under SOLAS, enclosed-space entry and rescue drills must be conducted at least once every two months.

Why do most deaths occur during rescue?

Because would-be rescuers rush in without breathing apparatus or planning. Always use BA and retrieval systems.

What gases are most common in fatal incidents?

Hydrogen sulphide, carbon monoxide, and carbon dioxide are the main killers due to invisibility and rapid incapacitation.

Can portable gas meters fail?

Yes—through poor calibration, low battery, or sensor poisoning. Always bump-test before use.

How can smaller ships improve compliance?

Simplify paperwork but never skip steps. Use laminated checklists, bilingual permits, and regular toolbox talks.

What’s the best long-term prevention?

Culture. Make “stop and test” instinctive. Reward people for refusing unsafe entries rather than rushing the job.

Conclusion

Every enclosed-space fatality is a chain of small decisions that went the wrong way: one shortcut, one assumption, one misplaced sense of urgency. The best protection is not heroism—it’s procedure, practice, and peer pressure that works in the right direction.

For officers, that means enforcing the permit system. For cadets, it means asking before acting. For managers, it means budgeting for drills and calibration. And for the entire maritime community, it means refusing to normalize risk in the dark corners of our ships.

The sea will always test us. Let’s not add hidden airless rooms to its challenges.

References

-

International Maritime Organization (IMO). Revised Recommendations for Entering Enclosed Spaces Aboard Ships (Resolution A.1050(27)).

https://www.imo.org/en/OurWork/Safety/Pages/enclosed-spaces.aspx -

SOLAS Consolidated Edition 2020, Regulation III/19 – Enclosed Space Entry and Rescue Drills.

https://www.imo.org/en/About/Conventions/Pages/SOLAS.aspx -

International Safety Guide for Oil Tankers and Terminals (ISGOTT), 6th Edition, 2020.

https://www.ocimf.org/publications/international-safety-guide-for-oil-tankers-and-terminals -

InterManager. Global Enclosed Space Deaths Report (2024).

https://intermanager.org/2024/03/enclosed-space-report -

The Nautical Institute. The Human Element in Enclosed Space Accidents.

https://www.nautinst.org/resources-page/the-human-element-in-enclosed-space-accidents.html -

UK Maritime and Coastguard Agency (MCA). Code of Safe Working Practices for Merchant Seafarers (COSWP), Chapter 15: Enclosed Spaces.

https://www.gov.uk/government/publications/code-of-safe-working-practices-for-merchant-seafarers -

EMSA. Annual Overview of Marine Casualties and Incidents 2023.

https://www.emsa.europa.eu/publications/item/5112-annual-overview-of-marine-casualties-and-incidents-2023.html -

The Standard Club (NorthStandard P&I). Loss Prevention: Entry into Enclosed Spaces.

https://www.standard-club.com/en/knowledge-publications/loss-prevention-safety-guides -

UK P&I Club. Safety Bulletins: Fatalities in Enclosed Spaces.

https://www.ukpandi.com/news-and-resources -

Australian Maritime Safety Authority (AMSA). Marine Notice 11/2022 – Entry into Enclosed Spaces.

https://www.amsa.gov.au/vessels-operators/domestic-commercial-vessels/safety-management-systems -

Maritime and Coastguard Agency (MAIB). Safety Digest 1/2024: Learning from Marine Accident Investigations.

https://www.gov.uk/maib-reports -

Lloyd’s Register. Guidance Notes on Enclosed Space Entry on Board Ships.

https://www.lr.org/en/insights/articles/enclosed-space-entry-guidance