Discover the top 12 bunkering accidents that shaped maritime safety. Learn real-world lessons from spills, fires, and operational failures, and see how regulations, training, and technology are transforming bunkering practices worldwide.

Why Bunkering Safety Matters in Modern Shipping ⚓

Bunkering—the process of transferring fuel oil to ships—is one of the most routine yet risky operations at sea. Whether in port, at anchorage, or ship-to-ship (STS) transfers, bunkering demands precision, discipline, and trust. A single mistake can lead to oil spills, fires, explosions, financial loss, reputational damage, and even loss of life. Despite international regulations, including MARPOL Annex I and IMO guidelines, bunkering accidents continue to occur. They remind us that safety in bunkering is not just about compliance—it’s about culture, training, and vigilance.

Bunkering—the process of transferring fuel oil to ships—is one of the most routine yet risky operations at sea. Whether in port, at anchorage, or ship-to-ship (STS) transfers, bunkering demands precision, discipline, and trust. A single mistake can lead to oil spills, fires, explosions, financial loss, reputational damage, and even loss of life. Despite international regulations, including MARPOL Annex I and IMO guidelines, bunkering accidents continue to occur. They remind us that safety in bunkering is not just about compliance—it’s about culture, training, and vigilance.

This article explores 12 significant bunkering accidents and the powerful lessons they leave behind. Each case illustrates what went wrong, what was learned, and how the maritime world can better safeguard bunkering operations by 2030.

Shipping carries 90% of global trade (UNCTAD, 2023), and every day, thousands of vessels take on fuel across the world. Bunkering safety matters because:

- Environmental stakes are high – A single spill can devastate marine ecosystems and coastal livelihoods.

- Regulatory compliance is strict – IMO, MARPOL, and classification societies impose heavy penalties for negligence.

- Economic losses are significant – Fines, delays, and compensation claims often exceed millions.

- Crew safety is paramount – Fires and toxic vapours can injure or kill crew within seconds.

Understanding past accidents is not just about history—it is a living manual for preventing future disasters.

–

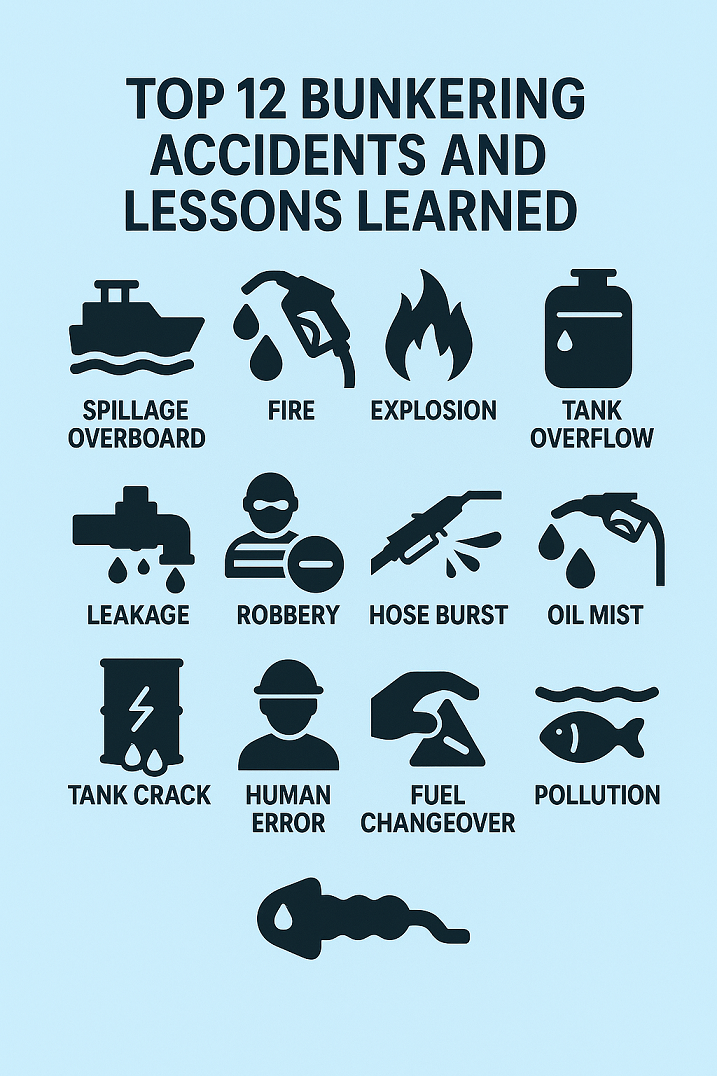

Top 12 Bunkering Accidents and Lessons Learned

1. Prestige Bunker Spill (Spain, 2002)

The 26-year-old tanker Prestige suffered a catastrophic hull breach in a storm off Galicia. As the ship was towed out to sea and eventually broke in two, it released approximately 63,000 tonnes of heavy fuel oil from its own bunker tanks into the ocean, causing one of Europe’s worst environmental disasters.

Lesson: Even beyond cargo, bunker fuel tanks can cause catastrophic pollution. This led to stricter double-hull requirements under MARPOL for bunker tanks.

2. Singapore Bunkering Spill (2014)

During a fuel transfer between the tanker Lime Galaxy and the bunker barge Marine Honour, a hose failure led to the release of over 4,500 tonnes of fuel oil. The spill contaminated Singapore’s southern shores, including the popular Sentosa Island beach, and required a massive and costly clean-up operation.

Lesson: Bunker operations in busy ports demand stricter oversight. Singapore introduced the Mandatory Bunkering License Scheme, requiring mass flow meters and tighter checks.

3. St. Petersburg Bunker Fire (2018)

While bunkering the chemical tanker NS Corinthian, a high-pressure fuel hose ruptured. The resulting mist of sprayed oil found an ignition source, causing a flash fire on deck that severely injured several crew members.

Lesson: Hose integrity and emergency shutdowns are critical. Today, most ports require certified hoses and periodic inspection regimes.

4. MSC Flaminia Explosion (2012, Mid-Atlantic)

A violent explosion occurred in a cargo hold of the container ship MSC Flaminia mid-voyage. The official investigation concluded the blast was likely caused by the ignition of flammable vapors from a leaking heating coil in a tank containing a chemical (DVB) that had self-polymerized. While not a bunkering accident, it centered on the hazards of flammable vapors from fuel/cargo handling.

Lesson: Fuel-related accidents show the importance of proper ventilation, monitoring, and inert gas systems.

5. Dubai Bunker Barge Collision (2015)

The bunker barge ALM Tana Zhi was alongside the bulk carrier Star Integrity for a fuel operation when rough seas or a loss of control caused the barge to collide with the ship. The collision breached the barge’s tank, spilling fuel into Port Rashid and halting marine traffic.

Lesson: Bunkering is not just about hoses—it requires navigational safety during ship-to-ship operations. Tug assistance and clear communication are vital.

6. Hong Kong Bunker Spill (2013)

During a bunkering operation, a valve was incorrectly opened on the barge, causing an estimated 80 to 100 tonnes of heavy fuel oil to overflow from the tanker’s air vent and spill into the sea. The oil slick polluted beaches and marine parks, requiring a large-scale response.

Lesson: Rapid spill response and emergency preparedness plans must be integrated into bunkering procedures.

7. Norwegian Ferry Bunkering Explosion (2007)

During the first-ever ship-to-ship transfer of Liquefied Natural Gas (LNG) as fuel to the ferry MS Viking Hell, a gas leak occurred. The accumulated vapor ignited, causing an explosion that damaged equipment but fortunately resulted in no serious injuries.

Lesson: LNG bunkering requires different protocols from oil bunkering, including dedicated training and risk assessment for cryogenic fuels.

8. Port of Rotterdam Bunkering Fire (2016)

A bunker barge was supplying fuel to the chemical tanker Bow Jubail when a fire broke out on the tanker’s deck. The investigation pointed to a “hot surface” or spark igniting fuel vapors. The fire spread rapidly, causing significant damage.

Lesson: Hot work and bunkering are incompatible. ISGOTT and port regulations now strictly forbid simultaneous hot work and bunkering.

9. South Korean Bunker Spill (2019)

The small chemical tanker White Sirius was receiving fuel from a barge in Yeosu when a miscommunication or error led to the incorrect operation of tank valves. This caused fuel to overflow through a vent pipe into the sea.

Lesson: Human error remains the leading cause. Comprehensive training and simulation exercises can reduce valve mismanagement risks.

10. Genoa Ferry Bunkering Incident (2017)

As the ferry Moby Fantasy was taking on fuel, a high-pressure hose suddenly burst at a coupling. The force of the rupture whipped the hose and released a jet of oil, dousing several crew members and causing chemical burns and injuries.

Lesson: PPE (Personal Protective Equipment) and safety zones around hoses must be non-negotiable.

11. Durban Bunkering Oil Spill (2020)

A hose failure during a bunkering operation on the bulker SM Newworld resulted in a significant spill within the confines of Durban’s harbour. The response was criticized as slow, allowing oil to spread and shoreline contamination.

Lesson: Port-state monitoring and joint accountability between suppliers and shipowners are essential.

12. Valdez Marine Terminal Near-Miss (2021, Alaska)

During a routine fuel transfer at the iconic Alyeska terminal, a degraded gasket on a manifold began leaking under pressure. The crew’s swift action to initiate emergency procedures and contain the leak successfully prevented what could have been a major spill in a highly sensitive environment.

Lesson: Near-misses are warnings. Every close call must be documented, reported, and analysed to prevent future accidents.

–

Common Causes of Bunkering Accidents

-

Human error – Miscommunication, fatigue, or inexperience.

-

Equipment failure – Hoses, valves, or pumps not properly maintained.

-

Procedural lapses – Incomplete checklists or missing permits.

-

Weather conditions – Strong currents, winds, or poor visibility.

-

Regulatory non-compliance – Bypassing safety requirements.

Challenges and Solutions in Bunkering Safety

Challenge: Increasing use of new fuels (LNG, methanol, ammonia).

👉 Updated training under STCW, and new class society guidelines (DNV, LR, ABS).

Challenge: Misaligned global regulations.

👉 Wider adoption of IMO Guidelines for Bunkering and local enforcement (e.g., Singapore MPA).

Challenge: Lack of standardised reporting.

👉 Use of digital bunkering platforms and blockchain transparency.

Real-World Safety Improvements Since Major Accidents

-

Singapore’s Mass Flow Meter mandate (2017) reduced disputes and improved transparency.

-

ISGOTT guidelines made simultaneous operations (SIMOPS) safer.

-

LNG bunkering standards (ISO/TS 18683:2015) are now globally recognised.

-

P&I Club training programmes now integrate case studies of past bunkering incidents.

FAQs

1. What is the most common cause of bunkering accidents?

Human error, particularly poor communication and failure to follow checklists.

2. How are bunkering spills different from cargo spills?

Bunkering spills usually involve heavy fuel oil, which is harder to clean and causes severe localised damage.

3. Are LNG bunkering accidents more dangerous than oil spills?

They pose different risks—explosions and cryogenic burns rather than pollution.

4. Who is responsible if a bunkering accident occurs?

Liability can fall on the shipowner, bunker supplier, or port authority depending on contractual and regulatory frameworks.

5. How do ports prevent bunkering accidents?

Through strict licensing schemes, monitoring, emergency drills, and real-time reporting systems.

6. What is the role of classification societies in bunkering safety?

They provide technical rules, certify equipment, and ensure training standards align with evolving fuels.

7. Can technology completely eliminate bunkering accidents?

Not entirely, but automation, digital monitoring, and AI systems greatly reduce risks.

Conclusion: Safety Is a Shared Responsibility 🚢

Bunkering accidents remind us that no operation is routine when fuel is involved. From small spills to catastrophic explosions, every case has shaped today’s stricter safety culture.

By 2030, as the industry embraces alternative fuels, digitalisation, and stricter environmental rules, bunkering will look very different. But the core lesson remains timeless: safety depends on people, preparation, and vigilance.

For maritime professionals, students, and enthusiasts, studying past bunkering accidents is not about blame—it’s about building a safer, cleaner future for global shipping.