Water mist systems utilize high-pressure water jets to create a fine mist that can effectively suppress fires. Unlike traditional sprinkler systems that release large droplets of water, water mist systems produce tiny droplets ranging from 50 to 200 microns in diameter. This fine mist has several advantages, including a larger surface area for heat absorption and rapid evaporation, which enhances the cooling effect on the fire.The operational principle of water mist systems revolves around three key mechanisms: cooling, oxygen displacement, and smoke suppression. When the fine mist is introduced into a fire, it absorbs heat quickly, reducing the temperature of the flames. Additionally, as the water droplets evaporate, they displace oxygen in the vicinity of the fire, further inhibiting combustion. The system also helps to settle smoke particles, improving visibility and air quality during emergencies.

Regulatory Framework

The implementation of water mist fire fighting systems on ships is governed by several international regulations and standards. The most significant among these are outlined in the International Convention for the Safety of Life at Sea (SOLAS), the International Maritime Organization (IMO) guidelines, and various national regulations. Under SOLAS Chapter II-2, regulations require that ships be equipped with adequate fire-fighting systems. Water mist systems are recognized as an acceptable alternative to traditional fire suppression methods in certain applications, particularly in machinery spaces and engine rooms. The IMO has established guidelines for the design and installation of water mist systems on ships. These guidelines ensure that systems are effective in controlling fires while minimizing risks to personnel and equipment. Many countries have adopted their own regulations regarding fire safety on ships. These regulations often align with international standards but may include additional requirements specific to local conditions or practices.

Advantages of Water Mist Systems

Water mist fire fighting systems offer several advantages over traditional fire suppression methods:

- Reduced Water Usage: Water mist systems use significantly less water than conventional sprinklers, making them ideal for protecting sensitive equipment in engine rooms where excessive water could cause damage.

- Environmental Safety: By using potable water instead of chemicals like Halon or foam agents, water mist systems are environmentally friendly and comply with international regulations aimed at reducing harmful emissions.

- Versatility: Water mist systems can be adapted for various applications on board ships, including engine rooms, cargo holds, and passenger areas. Their effectiveness against different types of fires—such as those involving flammable liquids or electrical equipment—makes them a versatile choice for marine fire protection.

- Quick Activation: These systems can be activated quickly in response to a fire alarm or manually by crew members, ensuring rapid response times that are critical during emergencies.

Operational Mechanism and Installation Considerations

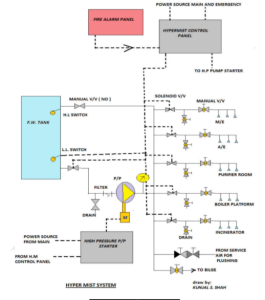

The operation of a water mist system begins with a detection system that identifies signs of a fire. Once detected, solenoid valves open to release pressurized water through specially designed nozzles. The nozzles atomize the water into fine droplets that form a mist cloud around the fire.The pressure at which water is delivered plays a crucial role in the effectiveness of the system. Most marine water mist systems operate at pressures between 4 to 10 MPa (approximately 580 to 1,450 psi). This high pressure is essential for creating the fine droplets necessary for effective heat absorption and oxygen displacement.The system typically draws water from a dedicated fresh water tank or can switch to seawater if necessary. It is designed to maintain a constant state of readiness, ensuring that adequate water supply is available at all times. For instance, it is common practice to ensure that there is enough fresh water in reserve for at least 20 minutes of operation during an emergency.

When installing a water mist system in an engine room or other critical areas on board a ship, several factors should be considered:

- Nozzle Placement: The distance between nozzles must be calculated carefully to ensure complete coverage of protected areas without leaving any gaps where fires could spread unnoticed.

- System Design: Each installation should be tailored to the specific layout and hazards present in the engine room. This includes considerations for ventilation systems that could impact how effectively the mist disperses during a fire.

- Integration with Other Systems: Water mist systems should be integrated with other fire safety measures on board, such as alarms and emergency lighting systems. This integration enhances overall safety by providing comprehensive protection against multiple hazards.

Credit: https://knowledgeofsea.com/operation-of-hyper-mist-system/

Automatic and Manual Operation of Water Mist Fire Fighting Systems

Water mist fire fighting systems are designed to provide effective fire suppression in critical areas such as engine rooms on ships. These systems can operate automatically or manually, ensuring flexibility in response to fire emergencies. Understanding how these operational modes function is essential for crew members and safety personnel on board.

Automatic Operation

The automatic operation of a water mist fire fighting system relies on a network of detectors strategically placed over protected areas, which may include the main engine, auxiliary engines, incinerators, auxiliary boilers, and purifiers. Typically, two types of detectors are employed: a smoke detector and a flame detector. This dual-detection approach enhances the system’s reliability by ensuring that different fire conditions can be accurately identified.When a fire occurs, if only one detector is activated, the system triggers a fire alarm as a pre-warning. This early warning allows crew members to assess the situation and prepare for potential escalation. However, if both detectors are activated, the information is transmitted to the main control panel of the water mist fire extinguishing system. At this point, the system automatically initiates several actions:

- Activation of Water Pump: The control panel starts the water pump, which is crucial for generating high-pressure water necessary for effective mist formation.

- Opening of Solenoid Valve: The solenoid valve specific to the affected area opens, allowing pressurized water to flow towards the water mist nozzles.

Once activated, water at high pressure—typically around 10 bar—is directed to the nozzles. These nozzles atomize the water into fine droplets that form a mist and are sprayed over the area under threat. This fine mist effectively suppresses the fire through cooling and oxygen displacement mechanisms.The system is designed to discharge water mist continuously until it is manually stopped or until the fire is extinguished. According to international regulations, if necessary, water mist can be discharged for up to 20 minutes, providing sufficient time for effective firefighting efforts.

Manual Operation

In situations where immediate manual intervention is required or when automatic activation is not feasible, crew members can manually operate the water mist system. This is particularly useful in scenarios where early detection may not have occurred or when crew members are already aware of a fire situation.To manually activate the system, crew members can press the ‘START’ button located on either the local control panel or a remote control panel designated for that particular protected area. Upon activation:

- Pump Activation: The manual command starts the pump, similar to automatic operation.

- Solenoid Valve Engagement: The solenoid valve for the respective area opens, allowing high-pressure water to reach the nozzles.

This manual operation ensures that crew members have direct control over firefighting efforts and can respond quickly to emerging threats.

Case Studies

Several real-world incidents highlight the effectiveness of water mist fire fighting systems in maritime applications:

- MV Rena Incident (2011): During this incident off New Zealand’s coast, a container ship grounded and subsequently caught fire. The vessel was equipped with a high-pressure water mist system that played a critical role in controlling the blaze while minimizing damage to cargo and ship infrastructure.

- Ferry Fire (2017): A passenger ferry experienced an engine room fire while en route. The crew activated the onboard water mist system promptly, which effectively suppressed the flames before they could spread further into passenger areas. The quick response ensured passenger safety and prevented significant damage to the vessel.

These case studies underscore how effective training and well-designed fire suppression systems can mitigate risks associated with maritime operations.

Training and Maintenance

To ensure optimal performance of water mist fire fighting systems, regular training and maintenance are essential:

- Crew Training: All crew members should receive training on how to operate the system effectively during emergencies. This includes familiarization with activation procedures, nozzle operation, and understanding how to assess when it is safe to engage the system.

- Regular Inspections: Routine inspections should be conducted to verify that all components of the system are functioning correctly. This includes checking pressure levels, ensuring nozzles are unobstructed, and confirming that control valves operate smoothly.

- System Testing: Periodic testing of the entire system under simulated conditions helps identify any potential issues before they arise during an actual emergency. These tests should be documented as part of compliance with SOLAS regulations.

The implementation of water mist fire fighting systems in ship engine rooms represents a significant advancement in maritime safety technology. These systems provide effective fire suppression while minimizing environmental impact and equipment damage—a crucial consideration in modern maritime operations.As regulatory frameworks continue to evolve alongside advancements in technology, ship operators must remain vigilant about maintaining compliance with international standards while prioritizing crew training and system maintenance. By doing so, they can ensure that their vessels are equipped with effective means to combat fires efficiently while safeguarding lives at sea.In conclusion, understanding how these sophisticated systems work not only enhances operational safety but also contributes significantly to overall maritime safety culture—a vital aspect as shipping continues to grow globally amidst increasing environmental challenges.