Surging is usually first detected by noises from the air compressor side. The noises may differ but may include howling, whining, knocking and banging. The turbocharger may race intermittently; air discharge pressure will drop and behave erratically. Unless the surging becomes frequent or continuous it should not harm the turbocharger or engine, but loss of air will cause poor combustion with all its relative problems.

A sudden reduction in engine speed with the corresponding drop in demand for air may cause surging, but this is temporary and stable conditions are soon re-established.

Turbochargers are designed to avoid surging under normal operating conditions and a surge will indicate abnormal change in either air or exhaust gas flow to or from the charger. Turbochargers may be prone to surging if an engine is operated with one or more units not producing power.

Provided no sudden change in engine power has taken place, surging in a normally stable system while running can usually be traced to fouling. If this is on the air side it may be within the compressor, including the impeller and diffuser, intake filters, charge air cooler or choked scavenged ports. On the gas side it may be in the turbine at the nozzle ring or moving blades. It may also be due to choked grids or in a waste heat boiler.

As a temporary remedy, stability can be reinstated by reducing the engine speed and power. Measures must be taken as soon as convenient to remove the fouling. The first measure which can be carried out while the engine is operating is to water-wash the turbocharger.

Should the turbocharger vibrate and slow down, it should be stopped and examined for bearing damage or loss in balance.

A scavenge fire may lead to surging, but this becomes obvious from its other effects.

Surging Theory

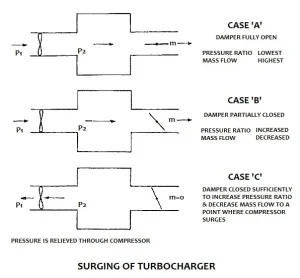

Turbocharger surging is an unstable condition characterized by irregular pressure pulsations and noise, caused by disruptions in the balance between the mass flow rate of air and the pressure ratio across the compressor. To understand this phenomenon, refer to the diagram showing three different damper positions and their effects on compressor performance:

-

Case ‘A’ – Damper Fully Open

In this condition, the damper presents minimal resistance. As a result:-

Mass flow rate is at its highest.

-

Pressure ratio (P2/P1) is at its lowest.

-

Air flows freely through the system without obstruction.

-

-

Case ‘B’ – Damper Partially Closed

Throttling the damper introduces moderate resistance:-

Mass flow rate decreases.

-

Pressure ratio increases.

The compressor is still stable but is now working under more restrictive conditions.

-

-

Case ‘C’ – Damper Significantly Closed

If the damper is closed too much or too quickly:-

The mass flow rate becomes too low.

-

The pressure ratio becomes excessively high.

This causes the flow of air to break down. At this point, the pressure cannot be sustained and is relieved back through the compressor, leading to a reversal or backflow of air.

-

This condition is known as turbocharger surging. It is often accompanied by loud sounds such as gulps, howling, or banging, and can be damaging if not controlled.

–

Download the complete ABB Turbocharger product catalog here

–

FAQ

1. What is turbocharger surging?

Surging is a disruptive instability where airflow through the compressor reverses intermittently, causing erratic pressure drops, loud noises (howling/banging), and turbo speed fluctuations.

2. What are the common symptoms of surging?

- Unusual noises (howling, whining, knocking).

- Erratic air discharge pressure.

- Intermittent turbocharger racing or slowdown.

- Poor combustion due to reduced airflow.

3. What causes surging in turbochargers?

- Abrupt engine load changes (e.g., sudden speed reduction).

- Fouling: Air-side (dirty filters, charge cooler, compressor) or gas-side (clogged nozzle rings, turbine blades).

- Scavenge fires (rare but identifiable via other fire symptoms).

- Engine imbalance (e.g., some cylinders not firing).

4. Is surging harmful to the turbocharger?

Occasional surging may not cause immediate damage, but frequent or prolonged episodes risk bearing wear, imbalance, or mechanical failure.

5. How can surging be temporarily controlled?

Reduce engine speed/power to stabilize airflow. Water-washing the turbocharger (if equipped) may help clear minor fouling.

6. What are long-term solutions to prevent surging?

- Regular cleaning of air filters, charge coolers, and turbine components.

- Monitoring engine balance (ensure all cylinders contribute power).

- Avoiding abrupt load changes where possible.

7. When should a surging turbocharger be shut down?

If surging is accompanied by severe vibration or slowdown, immediate shutdown is required to inspect bearings and rotor balance.

–

References

-

Watson, N. & Janota, M. S. (1982). Turbocharging the Internal Combustion Engine. Macmillan.

-

Heywood, J. B. (2018). Internal Combustion Engine Fundamentals (2nd ed.). McGraw-Hill.

- Diesel Engines, 3rd edition by WHARTON

-

MAN Energy Solutions. (2020). Turbocharger Surging: Causes and Countermeasures (Technical Bulletin).

-

ABB Turbocharging. (2019). Maintenance Guide for Turbochargers in Marine Applications.

-

International Maritime Organization (IMO). (2016). Engine Room Operational Best Practices (MEPC.1/Circ.795).