Discover the top 12 roles of an engine room crew explained in detail. Learn how marine engineers, oilers, and support staff keep ships safe, efficient, and compliant with international maritime standards in this comprehensive guide.

Engine Room: The Beating Heart of a Ship

If the bridge is the brain of a ship, then the engine room is surely its heart. Hidden below deck, often out of sight to passengers and even some crew, the engine room is a hive of constant motion. Temperatures can soar above 45°C, machinery roars day and night, and the slightest mistake can ripple across an entire voyage. The engine room crew are the unsung heroes of maritime operations. They keep propulsion systems running, ensure electricity is available throughout the vessel, treat water, manage fuel, and even handle firefighting systems. Without them, ships—whether tankers, cruise liners, or cargo carriers—would grind to a halt.

If the bridge is the brain of a ship, then the engine room is surely its heart. Hidden below deck, often out of sight to passengers and even some crew, the engine room is a hive of constant motion. Temperatures can soar above 45°C, machinery roars day and night, and the slightest mistake can ripple across an entire voyage. The engine room crew are the unsung heroes of maritime operations. They keep propulsion systems running, ensure electricity is available throughout the vessel, treat water, manage fuel, and even handle firefighting systems. Without them, ships—whether tankers, cruise liners, or cargo carriers—would grind to a halt.

In this article, we break down the 12 most important roles in the engine room , explaining what they do, why they matter, and how international regulations such as the STCW Convention and IMO guidelines shape their work. This is not just technical detail—it’s the story of human skill, teamwork, and resilience at sea.

Modern ships are floating power plants. A large container ship, for example, can carry engines exceeding 80,000 horsepower, consuming more than 200 tons of fuel a day. Such systems require constant monitoring, troubleshooting, and maintenance.

An engine room crew is not just about turning wrenches; it’s about risk management and safety assurance. Fires, fuel leaks, or a loss of power (a “blackout”) can have devastating consequences. The Marine Accident Investigation Branch (MAIB) reports multiple cases where poor engine room management led to collisions, groundings, or pollution. By understanding the distinct responsibilities of each role, maritime students and professionals gain insight into how teamwork, regulation, and technology intersect in one of the toughest environments on Earth.

–

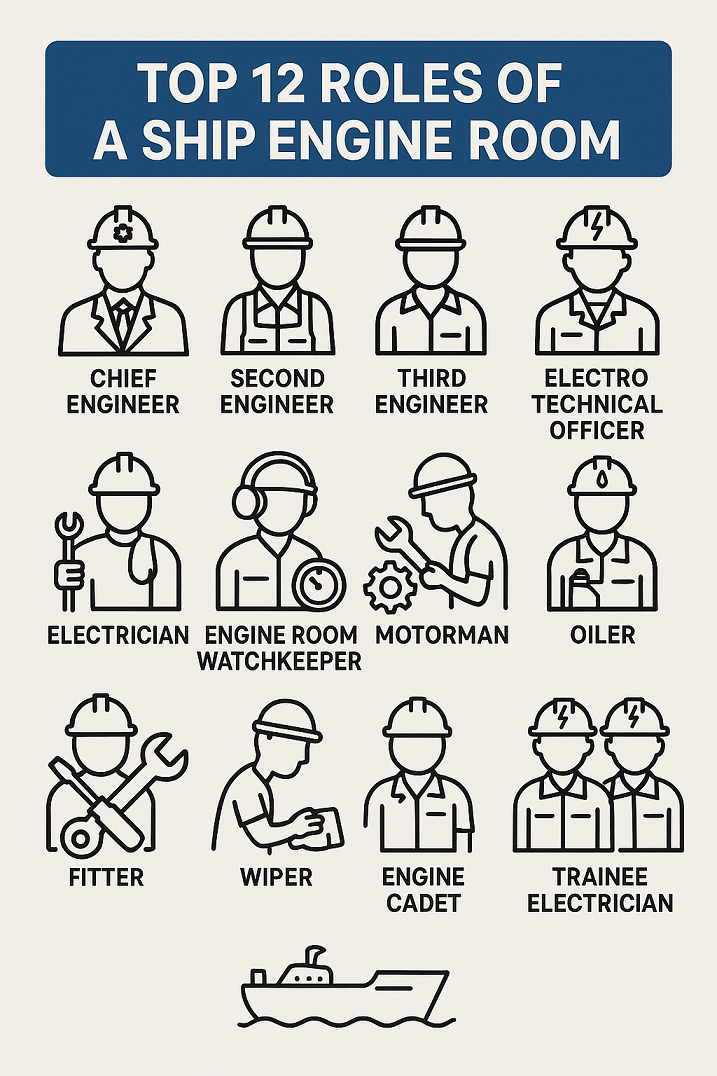

The Top 12 Roles of an Engine Room Crew Explained

The engine room of a ship is often called its “heart,” and for good reason. Beneath the decks, away from the passengers and cargo, a team of skilled professionals ensures that every piece of machinery operates safely, efficiently, and in compliance with international maritime regulations. From the Chief Engineer who oversees it all, to the Wiper taking their very first steps at sea, each role is essential.

In this article, we explain the 12 key engine room positions, connecting them with training standards, certification requirements, real-world responsibilities, and maritime regulations such as the STCW Convention, SOLAS, and MARPOL.

1. Chief Engineer (CE) – The Master of Machinery

The Chief Engineer is the head of the engine department, often described as the ship’s “technical CEO.” They carry ultimate responsibility for the performance and safety of all machinery on board, including propulsion engines, auxiliary systems, lifeboat davits, and even the air-conditioning plant.

To reach this rank, an officer typically spends many years progressing through junior positions, accumulating sea time, and passing increasingly difficult written and oral examinations. The mandatory license is a Class 1 Certificate of Competency (CoC) issued by a maritime authority such as the UK MCA, USCG, or Panama Maritime Authority, in strict accordance with the STCW Convention.

The Chief Engineer must ensure full compliance with SOLAS (safety) and MARPOL (pollution prevention), manage budgets and spare parts, liaise with classification societies like DNV or ABS, and keep meticulous maintenance logs.

A striking example of their importance came during the Ever Given grounding in the Suez Canal (2021), when engineers worked tirelessly to keep auxiliary systems running during the salvage effort. Without their input, the entire global operation could have been delayed even further.

2. Second Engineer (2/E) – The Chief’s Right Hand

The Second Engineer acts as the operations manager of the engine room. While the Chief sets strategy, the Second ensures execution. They supervise daily maintenance, repair schedules, and fuel operations, while also leading emergency drills and standing a watch.

This role requires a Class 2 CoC under STCW, which authorizes service as Chief Engineer on smaller vessels or Second Engineer on larger ones.

From monitoring lubrication and cooling systems to overseeing boiler operations, the Second Engineer’s vigilance can mean the difference between smooth sailing and costly breakdowns. A proactive Second Engineer often detects early warning signs—such as fuel contamination or bearing overheating—that, if ignored, could lead to serious damage and voyage delays.

3. Third Engineer (3/E) – Guardian of Auxiliary Systems

The Third Engineer’s primary responsibility lies in the ship’s auxiliary systems: electrical generators, fuel and lube oil purifiers, air compressors, sewage treatment plants, and boilers. On many ships, they also maintain firefighting equipment and emergency systems.

This rank requires a Class 3 CoC under STCW, marking the officer’s first opportunity to keep a watch independently.

On a cruise ship, for instance, the Third Engineer ensures uninterrupted electricity for kitchens, medical facilities, elevators, and entertainment systems—keeping thousands of passengers comfortable without them ever realizing the complexity below decks.

4. Fourth Engineer (4/E) – The Rookie with Responsibility

The Fourth Engineer is the most junior licensed officer, but their role is anything but minor. They typically handle tasks related to fuel transfer, lubrication systems, and watchkeeping under the supervision of senior officers.

To qualify, they must complete a cadetship that combines academic study with mandatory sea time and pass the first set of engineering exams, leading to a Class 4/5 CoC or Officer of the Watch (OOW) Unlimited license under STCW.

This stage is crucial in shaping future engineers, as it offers hands-on exposure to real shipboard machinery. Many senior engineers look back fondly on their time as Fourth Engineers, when they learned the fundamentals of responsibility and teamwork.

5. Electro-Technical Officer (ETO) – The Digital Specialist

Modern ships are increasingly dependent on automation, and this is where the Electro-Technical Officer comes in. ETOs are specialists in electrical power systems, electronic controls, navigation and communication equipment, and high-voltage switchboards.

They follow a distinct training and licensing path under STCW Regulation III/6, often through a dedicated ETO cadetship.

Their importance has grown rapidly: a 2020 DNV report highlighted that automation failures are now a major cause of ship detentions. Skilled ETOs help prevent such risks by maintaining alarm systems, sensors, and computer-based monitoring platforms.

6. Motorman – The Backbone of Manual Operations

Motormen provide the essential link between the officers and support crew. They carry out daily inspections of pumps, filters, valves, and auxiliary equipment, while assisting during overhauls and sounding tanks.

Although not always licensed officers, Motormen require strong technical knowledge and practical experience. They are often the first responders in emergencies and are described as the “unsung soldiers” of the engine room.

7. Oiler – Keeping Things Moving Smoothly

The Oiler focuses on lubrication and machinery upkeep. They ensure moving parts are well-oiled, monitor temperature and pressure, and keep bilges clean.

A case recorded by the UK Marine Accident Investigation Branch (MAIB) shows why their role matters: poor lubrication checks once caused a generator seizure mid-Atlantic, underscoring that Oilers play a direct role in ship safety.

8. Wiper – The Entry-Level Starter

The Wiper is the lowest-ranking engine crew member, yet their contribution is fundamental. Their work includes cleaning, assisting Motormen and Oilers, and gradually learning engine room practices.

This position often marks the beginning of a long career at sea. Many Chief Engineers today can trace their first days back to sweeping engine room decks and scrubbing filters as Wipers.

9. Engineer Cadet – The Apprentice Engineer

Engine Cadets are students combining classroom theory with hands-on shipboard experience. Their tasks include shadowing engineers, assisting during bunkering operations, and joining safety drills.

Cadets must maintain a training record book, a requirement under STCW for progressing toward officer status. They represent the future of the maritime profession, ensuring continuity of knowledge and skills.

10. Pumpman – The Tanker Specialist

Unique to oil and chemical tankers, the Pumpman manages cargo pumping systems, stripping lines, and valves. They are indispensable during loading and discharging operations.

Pumpmen must be familiar with tanker safety frameworks such as the International Safety Guide for Oil Tankers and Terminals (ISGOTT) and the International Gas Carrier (IGC) Code.

For example, during a cargo discharge in Singapore, a Pumpman’s quick reaction to a pump seal failure prevented what could have been a serious spill.

11. Fitter / Machinist – The Engine Room Craftsman

Fitters are skilled metalworkers capable of repairing and fabricating parts at sea, often using lathes, welding machines, and other workshop tools. They fix cracked pipes, rebuild damaged valves, and create temporary spares in emergencies.

A documented case in Marine Structures Journal described how a bulk carrier’s fitter fabricated an emergency coupling mid-voyage after a ballast pump failure—a repair that saved the ship from delay.

12. Engine Room Storekeeper / Cook – The Dual Role on Small Ships

On smaller vessels, the role of storekeeper may be combined with that of crew cook. This person manages spare parts, inventories, and tools, while also preparing meals for the team.

Though unusual, this dual role has a significant impact: proper inventory control prevents costly downtime due to missing spares, and a hot meal after a long watch boosts crew morale in ways that can’t be underestimated.

–

Case Studies: Engine Room Teams in Action

Case 1: The Blackout in the Baltic

In 2019, a Ro-Ro ferry suffered a blackout due to a failed fuel pump. Thanks to coordinated teamwork between the Chief Engineer, Second Engineer, and Motormen, emergency generators were activated within minutes, averting disaster.

Case 2: Cruise Ship Comfort

During the COVID-19 repatriation voyages of 2020, engine crews worked tirelessly to maintain hotel loads (air conditioning, medical units, communications). Without them, humanitarian missions would have failed.

–

Challenges Facing Engine Room Crews Today

-

Decarbonisation Pressure – IMO’s GHG strategy pushes for alternative fuels like LNG, methanol, and ammonia, requiring retraining.

-

Automation – While ETOs are in demand, smaller crews mean higher workloads for those on board.

-

Safety Risks – Engine room fires remain among the top causes of major claims in P&I Clubs.

-

Fatigue – Long watches and small crew sizes increase human error risks.

Future Outlook: Engine Rooms in 2030 and Beyond

By 2030, ships may see:

-

Hybrid power systems combining diesel, batteries, and fuel cells.

-

Digital twins to simulate machinery performance.

-

AI-assisted maintenance reducing manual inspections.

-

Green roles like “Fuel Transition Engineer” emerging.

Yet, despite technological change, the human factor—judgement, skill, adaptability—will always remain central.

Frequently Asked Questions (FAQ)

1. What qualifications do you need to work in a ship’s engine room?

Most roles require STCW certifications, medical fitness, and structured sea-time experience.

2. What’s the hardest job in the engine room?

Many say Motormen and Oilers face the toughest physical work, while the Chief Engineer carries the most responsibility.

3. Are engine rooms dangerous?

Yes, due to high temperatures, noise, and fire hazards. Strict SOLAS safety protocols are enforced.

4. Do all ships carry a Pumpman?

No, Pumpmen are mostly on tankers and chemical carriers.

5. How do engine cadets progress to officers?

Through sea-time records, exams, and successful completion of STCW-approved training.

6. How is decarbonisation changing engine room work?

Crews now train on LNG bunkering, methanol handling, and emerging fuel technologies.

7. What’s the biggest challenge for engine crews today?

Balancing safety with efficiency under smaller crew sizes and tighter regulations.

Conclusion

The engine room is more than just machinery—it is a highly organized human system where every rank has a defined role, backed by international training standards, licensing regulations, and safety frameworks. From the Chief Engineer overseeing the big picture to the Wiper taking their first steps at sea, each member contributes to the smooth and safe operation of the vessel. Understanding these roles is not only valuable for maritime students and professionals but also for anyone seeking to appreciate the unseen workforce that keeps global trade afloat.

🚢 Next time you see a cargo ship on the horizon, remember: its real story is unfolding below deck, in the beating heart of the engine room.

References

-

IACS – International Association of Classification Societies

-

Marine Structures (Academic Journal)