Discover the top 10 fuel system problems on modern ships and how to prevent them. Learn practical insights into fuel contamination, injector wear, and fuel compatibility issues impacting maritime safety and efficiency.

Why Fuel System Integrity Matters in Modern Maritime Operations

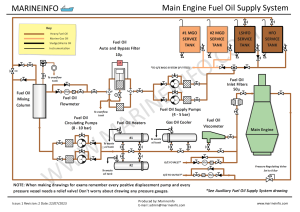

Modern ships are engineering marvels, crossing oceans with precision and efficiency. Yet beneath this polished performance lies a vulnerable core: the ship’s fuel system. This intricate network—from bunkering to injection—powers propulsion, generators, and boilers. When it malfunctions, the consequences range from reduced efficiency to catastrophic engine failure.

As marine fuels evolve under IMO 2020 sulfur limits, new fuels like Very Low Sulfur Fuel Oil (VLSFO) and biofuels are becoming the norm. While they reduce emissions, they also introduce new challenges: compatibility issues, instability, microbial growth, and increased sludge formation.

According to the International Chamber of Shipping (ICS) and DNV, over 40% of shipboard machinery failures are directly or indirectly linked to fuel system issues. This guide explores the top 10 fuel system problems on modern ships, how they arise, and what engineers and operators can do to detect and manage them.

The Changing Landscape of Marine Fuels

The implementation of MARPOL Annex VI and the IMO 2020 sulfur cap (<0.50% m/m) marked a turning point in marine fuel usage. While older vessels were designed for Heavy Fuel Oil (HFO), many now run on VLSFO, Marine Gas Oil (MGO), or dual-fuel LNG systems. This transition has introduced new fuel handling complexities, especially in aging systems not optimized for modern blends.

📘 Explore IMO 2020 Compliance Guidelines

Top 10 Fuel System Problems on Modern Ships

1. Fuel Contamination (Water, Sludge, Particulates)

Contaminants enter the fuel system during bunkering, storage, or condensation in tanks. Water, rust, and sludge impair combustion and cause wear in injectors and pumps.

Impact:

-

Injector clogging

-

Reduced combustion efficiency

-

Corrosion of fuel system components

Preventive Measures:

-

Regular draining of settling tanks

-

Fuel sampling and lab testing

-

Efficient purification (centrifugal separators or filters)

🧪 Real Case: In 2018, over 100 ships globally reported clogged filters after bunkering contaminated VLSFO in Houston and Singapore.

2. Fuel Incompatibility (VLSFO Blending Issues)

Mixing different VLSFO batches can lead to asphaltene precipitation, forming sticky sludge that blocks filters and injectors.

Why It Happens: VLSFO is often blended from multiple refinery streams. Incompatibility arises from differences in aromaticity or viscosity.

Symptoms:

-

Filter clogging

-

Fuel pump overload

-

Engine derating

📘 DNV VLSFO Stability Guidance

3. Poor Fuel Viscosity Control

Modern fuel injection systems require precise viscosity—typically 10–15 cSt at injection temperature. Too high, and atomization suffers; too low, and pump lubrication fails.

Common Causes:

-

Malfunctioning viscosity regulators

-

Inaccurate steam heater controls

-

Sudden fuel changeovers

🛢 Tip: Use automatic viscosity control units and monitor fuel temperature closely during startup and load changes.

4. Fuel Pump Wear or Seizure

High-pressure fuel pumps suffer from:

-

Internal leakage

-

Scoring of plunger-barrel assemblies

-

Failure of delivery valves

Contributing Factors:

-

Abrasive particles in fuel

-

Poor lubrication (especially with low-viscosity fuels)

-

Incorrect maintenance intervals

Recommended Action:

-

Use inline duplex filters

-

Inspect pump performance trends via pressure logs

-

Overhaul pumps per OEM guidelines

5. Microbial Growth (“Diesel Bug”)

Bacteria and fungi thrive at the fuel-water interface in tanks, forming biomass and acid byproducts.

Consequences:

-

Corrosion in tank bottoms

-

Blocked filters

-

Degraded combustion quality

Solution:

-

Add biocides during long voyages

-

Regular tank cleaning

-

Avoiding long-term storage of partially filled tanks

🌡 Environmental Note: Biofuels are more hygroscopic, increasing microbial risks if not stabilized.

6. Fuel Leakage in High-Pressure Lines

Leaks at injector lines or pump flanges can:

-

Cause fires

-

Lead to engine shutdown

-

Trigger emergency stops

Detection:

-

Visible spray or oil mist

-

Fuel pressure drops

-

Fuel mist detector alarms (in enclosed engines)

📘 SOLAS Regulation II-2/4.2.2.5 mandates insulation shields for fuel pipe joints above 220°C.

7. Improper Fuel Changeover (HFO to MGO)

Sudden fuel changeover can:

-

Thermally shock injectors

-

Cause viscosity mismatch

-

Lead to airlocks or filter blockage

Best Practice:

-

Use gradual blending transitions

-

Allow sufficient heating/cooling time

-

Monitor differential pressures during switching

🔁 Example: Before entering an Emission Control Area (ECA), vessels must switch from HFO to MGO, requiring careful timing to avoid system stress.

8. Clogged Fuel Filters and Strainers

Clogging is often the first symptom of broader fuel issues (e.g., instability or contamination).

Indicators:

-

Increased pressure drop across filters

-

Frequent cleaning requirements

-

Unexpected engine shutdowns

Preventive Steps:

-

Use duplex filters to allow changeover

-

Conduct weekly inspections

-

Monitor pressure differential trends

9. Air in Fuel Lines

Air bubbles entering fuel injection lines disrupt pressure and combustion.

Causes:

-

Suction leaks

-

Incomplete priming

-

Faulty O-rings or flanges

Symptoms:

-

Engine misfiring

-

Irregular RPM

-

Starting difficulties

💡 Troubleshooting Tip: Bleed lines at vent points before start-up, especially after filter replacement or system maintenance.

10. Incorrect Purifier Operation

Centrifugal purifiers fail due to:

-

Incorrect temperature-viscosity settings

-

Wrong gravity disc sizing

-

Blocked sludge discharge ports

Consequences:

-

Poor separation

-

Sludge buildup

-

Contaminated fuel reaching engines

Preventive Actions:

-

Train engineers in purifier optimization

-

Follow OEM-specific parameters

-

Schedule regular disassembly and cleaning

📘 IMO Training Requirements under STCW A-III/1

Credit: https://marineinfo.com/main-engine-fuel-oil-supply-system/

Real-World Case: Fuel System Failure and Emergency Shutdown

In 2021, a large container ship operating in the Mediterranean experienced a main engine stoppage during port approach. Investigations revealed:

-

Sudden fuel changeover to an unstable VLSFO

-

Asphaltene fallout clogged the fine filters

-

Backup fuel line had air pockets due to poor priming

Thanks to engineer intervention and auxiliary generator stability, the vessel avoided grounding. The incident highlighted how simple oversights in fuel handling can escalate rapidly.

Frequently Asked Questions (FAQ)

Q1: What is the most common fuel-related problem on ships?

A: Fuel contamination (water and sludge) remains the most widespread and dangerous issue, especially with VLSFO.

Q2: Can modern fuel problems be avoided entirely?

A: Not entirely, but proactive maintenance, real-time monitoring, and proper training significantly reduce risks.

Q3: How do you test marine fuel for compatibility?

A: Use a spot test (ASTM D4740) or send samples to labs for compatibility and stability assessments before bunkering.

Q4: What is the role of an FO flow meter?

A: Measures fuel consumption, detects leaks, and improves efficiency monitoring for IMO DCS and SEEMP compliance.

Q5: Are biofuels safer than traditional marine fuels?

A: Biofuels lower emissions but are more prone to microbial growth and instability without proper additives.

Conclusion: The Engine’s Lifeblood Requires Precision

Fuel is not just a commodity—it’s the lifeblood of marine engines. As fuel standards shift and engine technologies evolve, seafarers must stay informed, vigilant, and proactive. From bunkering to combustion, every stage of the fuel system presents potential risks and opportunities for optimization.

Mastering fuel system management ensures not only compliance with global regulations, but also enhances operational reliability, crew safety, and environmental stewardship.

⛽ Looking for purifier optimization tutorials, bunker checklist templates, or STCW-compliant training? Visit MaritimEducation.com to fuel your maritime career with confidence.

References

-

International Maritime Organization. (2024). MARPOL Annex VI and IMO 2020 Guidelines. https://www.imo.org

-

International Chamber of Shipping. (2023). Fuel Management Best Practices. https://www.ics-shipping.org

-

DNV. (2022). Fuel Stability and Compatibility Advisory. https://www.dnv.com

-

Lloyd’s Register. (2022). Fuel Oil Bunkering and Handling Standards. https://www.lr.org