The maritime world relies heavily on electricity for operations ranging from navigation to the basic functioning of onboard appliances. This power is predominantly supplied by generators, making their efficient operation critical. An essential aspect of managing multiple generators aboard ships is their synchronization. This process ensures that all generators operate in harmony, sharing load equally without causing disturbances or inefficiencies in the power supply system.

The necessity for synchronization stems from the fluctuating demand for electricity on a ship. Generators must work collectively to respond to the dynamic power requirements while avoiding overloading any single unit. Efficient synchronization leads to a balanced power system that can accommodate growth in demand and emergency situations without compromising on operational efficiency or safety.

Understanding the Main Circuit Power Diagram

The main circuit power diagram (MCPD) is more than a mere schematic; it is the cornerstone of a ship’s electrical system. The MCPD details the electrical power distribution from the generation source to the various loads onboard a ship. It comprises generators, switchboards, distribution panels, and connected equipment. The MCPD serves as a navigational chart, directing the flow of electricity throughout the vessel and is instrumental in both planning and troubleshooting scenarios.

Key elements of an MCPD typically include:

- Generators: They are the primary source of power and are usually diesel-powered engines coupled with an alternator. On cargo ships, there may be multiple generators to provide redundancy and to share the electrical load.

- Switchboards: These are the interfaces where power is controlled and distributed. Main switchboards divide the power into manageable circuits, often separating propulsion, critical systems, and general ship operations.

- Distribution Panels: They further distribute power to sub-circuits for lighting, communication systems, cargo handling equipment, and other ship functions.

- Emergency Generator: This is a separate system designed to provide power to critical systems in the event of a main generator failure.

- Shore Power Connection: Known as “cold ironing,” this allows the ship to connect to a port’s electrical grid to reduce emissions and generator wear while docked.

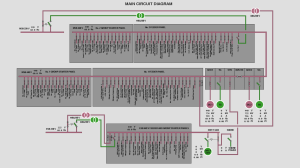

The above image is the “Main Circuit Diagram” of a ship. This diagram is a schematic representation of the ship’s main electrical distribution system, showing the connection between generators, bus bars, and various electrical panels. The ‘Main Circuit Diagram’ is a visual representation of a ship’s comprehensive electrical distribution system, detailing the interconnections between generators, bus bars, and various electrical panels. This diagram serves as a fundamental reference point for understanding how power sharing and redundancy are architected within the ship’s power matrix. The main elements include:

– Generators (GEN1 and GEN2) and Tie Switches: These symbols represent the ship’s generators and the connections that allow for power sharing and redundancy.

– Distribution Panels: Various feeder panels are illustrated, which distribute power to different sections of the ship.

– Emergency Generator (EMCY GEN): This is a backup power source to be used in case of a failure of the main generators.

– Shore Power Connection: When a ship is docked, it can draw electrical power from the shore through this connection to reduce generator usage.

Synchronization Process

Synchronization is the procedure of matching the voltage, frequency, phase angle, phase sequence, and waveform of one generator with another or with the grid. Synchronization is a multi-faceted procedure aimed at unifying the voltage, frequency, phase angle, phase sequence, and waveform across generators or between a generator and the grid. This alignment is paramount for several reasons:

– Voltage and Frequency Matching: Ensures a seamless power supply by aligning the output of all generators.

– Preventing Transient Phenomena: Minimizes voltage dips, surges, or frequency deviations during the synchronization process.

– Enhancing Grid Stability: In scenarios where ship generators are synced with a grid, synchronization supports the overall stability and reliability of the electrical supply.

The process involves several critical steps:

- Voltage Matching: Adjusting the generator’s output voltage to match the grid or reference generator.

- Frequency Matching: Aligning the generator’s frequency with that of the grid or another generator using speed control mechanisms.

- Phase Synchronization: Adjusting the phase angle to ensure it matches, often utilizing synchronizing devices like relays or synchroscopes.

- Circuit Breaker Closure: Once alignment in voltage, frequency, and phase is achieved, the generator is connected to the grid or other generators, beginning its power supply.

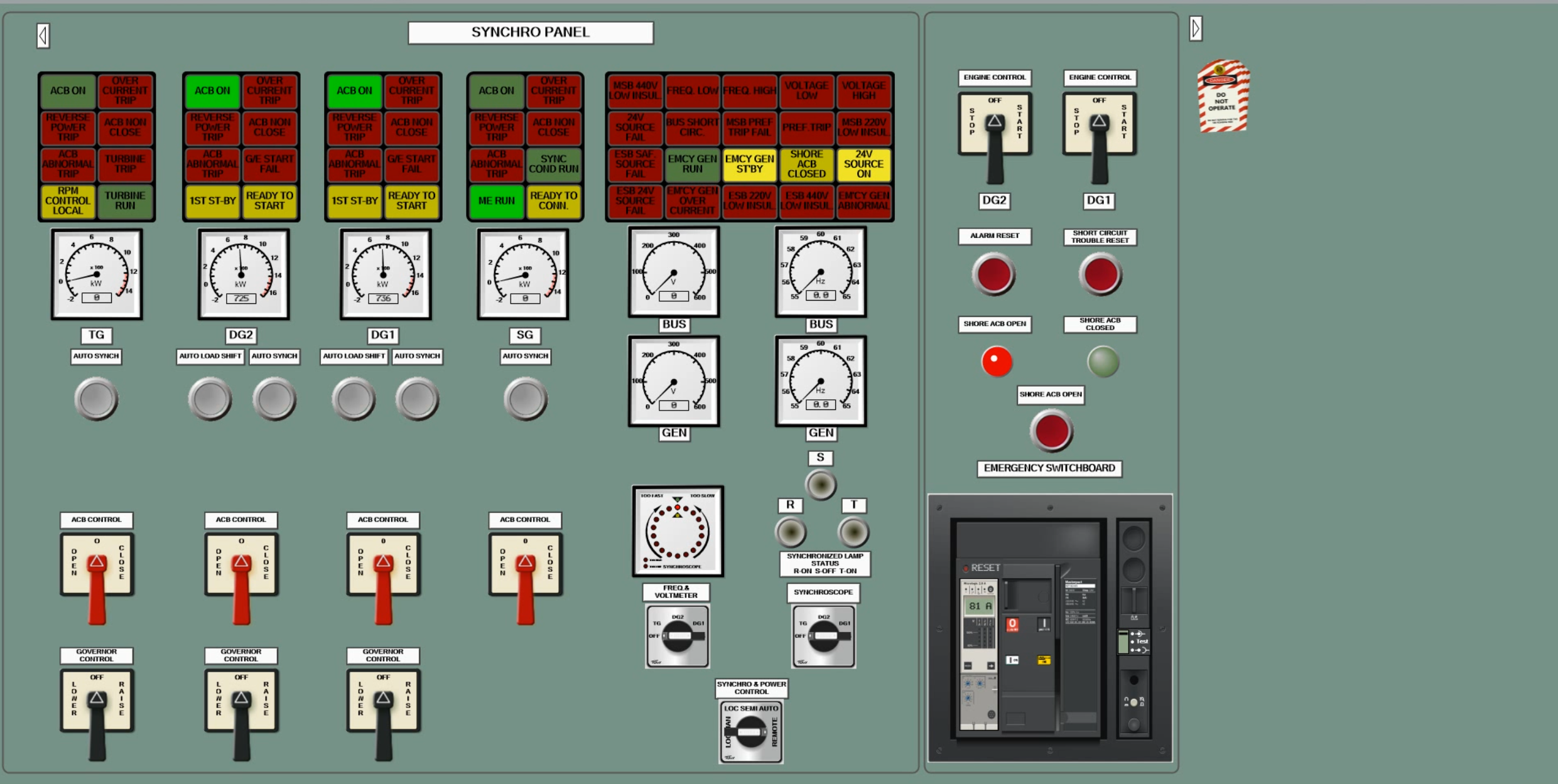

The above image, titled “Synchro Panel,” shows the control interface for managing generators on a ship. It includes various gauges, meters, and controls that are essential for monitoring and managing electrical power generation. Some key features of the synchro panel include:

- ACB (Air Circuit Breaker) Control Switches: These are used to open and close the circuit breakers, which control the flow of electricity from the generators.

- Generator Control and Monitoring: The gauges indicate important parameters such as kilowatts (kW), which measure power output, and other gauges for monitoring voltage and frequency.

- Auto Synchronizing and Load Sharing: Knobs and controls for auto synchronizing the generators and shifting load between them to ensure balanced power distribution and efficient operation.

- Engine Control: There are switches for starting and stopping the diesel generators (DG1 and DG2), along with emergency controls and indicators for electrical faults.

Load Sharing and Its Significance

Beyond the mechanical act of synchronization, the principle of load sharing holds equal significance, ensuring that the electrical burden is equitably distributed amongst the generators. This not only optimizes their usage, preventing individual generator overload, but also bolsters fuel efficiency and bolsters operational dependability. Load sharing brings with it the added advantage of redundancy, permitting other generators to compensate smoothly and maintain continuity in the event of a generator outage.

Load sharing encompasses measuring the load on each generator and adjusting their output to achieve an even distribution. This involves:

- Load Measurement and Adjustment: Using sensors to monitor load and controllers to adjust the generator’s output accordingly.

- Continuous Monitoring: Keeping track of the load distribution in real-time and making necessary adjustments to maintain the desired balance.

Why Synchronization and Load Sharing Are Important?

- Reliability and Efficiency: Synchronization and load sharing ensure a stable, efficient, and reliable power supply, crucial for the uninterrupted operation of ship functions.

- Maintenance and Operational Flexibility: These processes allow for easier maintenance and operational adjustments, ensuring that generators can be taken offline for service without disrupting the power supply.

The synchronization and load sharing of generators on ships are crucial for ensuring efficient, reliable, and safe electrical power supply. These processes not only optimize generator use but also enhance the overall stability of the ship’s electrical system, contributing significantly to the seamless operation of maritime vessels.