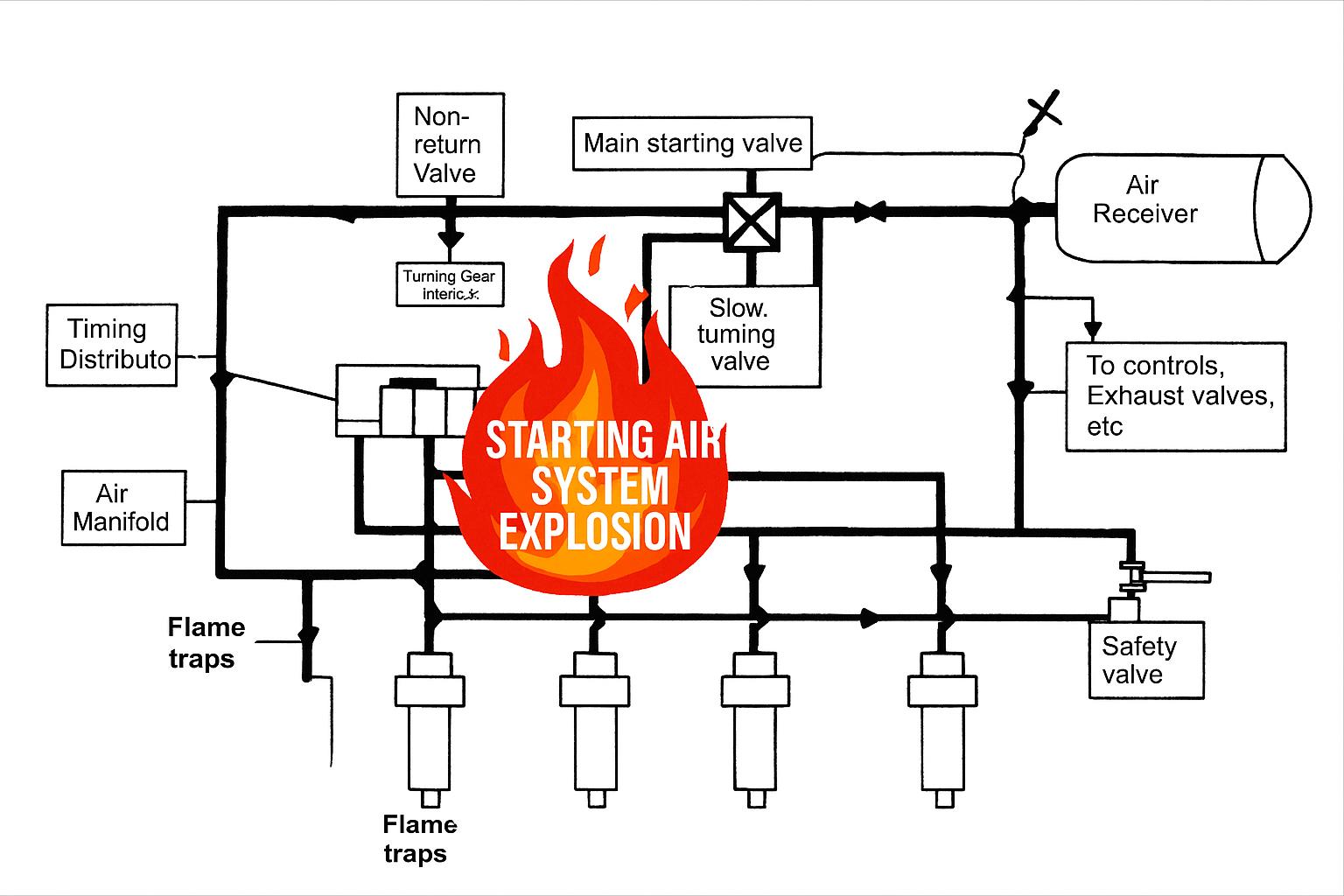

Typical marine diesel engine’s starting-air system

Possible causes of an explosion in high-pressure starting air pipelines are the continuous leaking of a defective cylinder non-return valve while the engine is operating, or such a valve sticking in the open position during manoeuvring.

Under normal operation, some lubricating oil mist may be discharged from the air compressor to the air start system. This oil may be from excess compressor cylinder lubrication, from faulty oil scraper rings, or may even be suspended oil vapour contaminating the engine room atmosphere and drawn in at the compressor suction. Oil discharge is kept to a minimum by draining the intercooler, receiver and starting system. If small quantities of lubricating oil do get into the starting air system, they will deposit as a thin mist on internal pipe surfaces but are not readily combustible.

If a cylinder non-return valve should leak while the engine is in operation, some hot gas, possibly with unburned fuel and cylinder lubricating oil, may be blown through the valve to the adjacent air manifold. With further heating from the leaky valve, this, together with the already deposited oil film, will carbonise and form incandescent carbon. If starting air is applied to the system while still hot, the high pressure air coming into contact with the burning carbon may cause an explosion. Such an explosion will cause a flame to pass back through the air start pipe system, evaporating the deposited oil film and igniting it in the presence of air. Very high velocities and shockwaves are generated which may rupture pipes and fittings.

Alternatively, fires/explosion may be created in the air start system. A mixture of air and oil droplets may be discharged through the open cylinder non-return valve during starting. This spray may ignite due to high temperatures in the cylinder, causing a flame through the still open valve to the air mainfold.

To prevent an explosion, air start valves must be correctly maintained and lubricated to ensure correct timing and free movement with positive closing. Oil in the system must be kept to a minimum, pipe lines must be drained and cleaned internally when necessary and oil discharge from air compressors must be kept to a minimum by good maintenance.

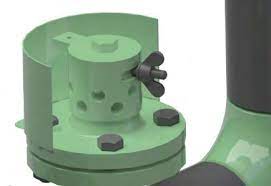

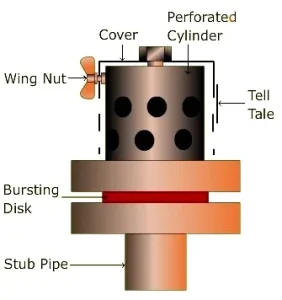

To minimise the effects of such explosions, the air start manifold to each cylinder valve must be fitted with a flame trap and ample relief valves. Bursting caps or discs must be fitted to relieve excess pressure. An isolating non-return valve is fitted at the outlet from the main control valve.

A leaking air start valve connected to the fusible outlet operated by local overheating of the pipe adjacent to the valve/if this should occur, the engine should be stopped at the first opportunity and the valve replaced. As a temporary measure, a blank flange may be fitted to the manifold flange to isolate this valve, since it will no longer operate it is not used again until the engine is shut down and will not readily restart. Warning should be transmitted to the bridge.

When the air start system is put into use, the oil drains should all be opened. Drains and collected oil removed from the system. Air start valves should be lubricated, where this is necessary, before the start of a voyage or during a long voyage when manoeuvring tests are made. Joints may be tested for tightness while in port by shutting down the system and all connections and applying air to the start manifold. Leaking joints or indicator cocks will disclose a leaking valve.

In the event of overheating of the compressor and the passage to the filling line, an explosion would be possible between the compressor and the air reservoir.

Flame traps for starting air lines on marine diesel engines

–

FAQ: Starting Air System Explosions

1. What triggers explosions in starting air systems?

- Leaking/stuck cylinder non-return valves, allowing hot exhaust gases (with unburned fuel/oil) to enter air pipes.

- Oil accumulation in pipelines igniting due to high temperatures or burning carbon deposits.

2. How does oil enter the system?

-

Excess lubrication from air compressors, faulty oil scraper rings, or contaminated engineroom air drawn into compressors.

3. Why are carbon deposits dangerous?

Incandescent carbon (from oil carbonization) can ignite when high-pressure air is applied, causing explosions and shockwaves.

4. What safety devices prevent explosions?

- Flame traps and relief valves on air manifolds.

- Bursting discs to vent excess pressure.

- Isolating non-return valves at the main control valve outlet.

5. How can risks be minimized?

- Regular maintenance: Ensure non-return valves seal tightly and pipelines are drained/cleaned.

- Pre-voyage checks: Lubricate air start valves and test system tightness.

- Monitor compressor oil discharge to avoid buildup.

6. What to do if a valve leaks during operation?

- Stop the engine at the earliest opportunity.

- Isolate the faulty valve with a blank flange (temporary fix).

- Transmit a warning to the bridge.

7. How are explosions detected early?

- Overheating pipes near valves (fusible outlets may melt to relieve pressure).

- Unexpected pressure surges or oil discharge from drains.

–

References

-

International Maritime Organization (IMO). (2014). Guidelines for the Safe Operation of Starting Air Systems (MSC.1/Circ.1369).

- Diesel Engines, 3rd edition by WHARTON

-

MAN Energy Solutions. (2021). Starting Air System Safety Manual.

-

American Bureau of Shipping (ABS). (2023). Rules for High-Pressure Air Systems on Marine Engines.

-

Lloyd’s Register. (2022). Prevention of Air Start System Explosions.

-

Wärtsilä. (2020). Maintenance Practices for Air Compressors and Starting Systems.

-

DNV GL. (2019). Explosion Risks in Marine Engine Air Systems.