In an age of heightened environmental awareness and stringent maritime regulations, waste management onboard commercial ships is of paramount importance. One of the most effective solutions to this challenge is the use of ship incinerators. This article delves into the nuances of modern ship incinerators, their operation, advantages, and associated regulations.

Incinerators onboard ships are designed to burn and dispose of solid and liquid waste, such as sludge oil, bilge, and other residues, reducing them to ash and inert gases. This not only aids in waste management but also reduces the amount of waste that needs to be offloaded in port, mitigating environmental risks [1].

Types of Incinerators

a. Marine Incinerator: Specifically designed for shipboard use, these are capable of handling mixed waste, including sludge oil, plastics, and food waste.

b. Sludge Oil Incinerator: Tailored mainly for burning oily waste and residues from shipboard operations.

c. Garbage Incinerator: Intended primarily for solid waste like plastics, paper, food scraps, etc. [2].

Operational Principles

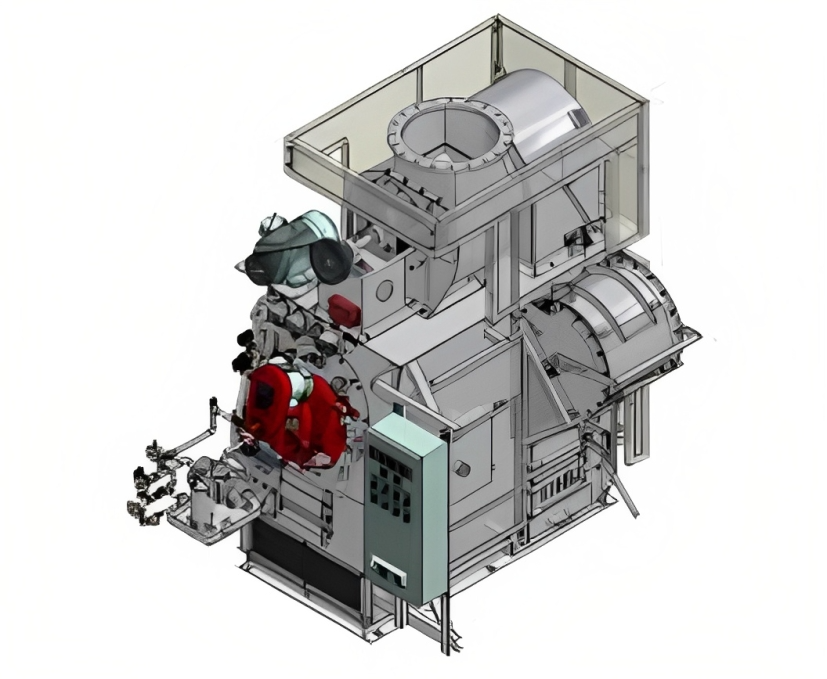

Dual Chamber Design: Most modern incinerators have a dual-chamber design. The primary chamber handles the actual waste burning at high temperatures, – while the secondary chamber treats and burns off the exhaust gases, reducing pollution [3]. Control Systems: Modern incinerators are equipped with advanced control systems that monitor temperature, pressure, and combustion efficiency, ensuring optimal and safe operations.

Advantages of Incinerators:

- Volume Reduction: Converts vast amounts of waste into minimal ash, dramatically reducing storage needs.

- Environmentally Friendly: Reduces the need to offload waste in ports, which might not have adequate waste handling facilities.

- Cost-Efficient: Reduces waste offloading costs and potential fines associated with non-compliance to waste disposal regulations.

- Bio-Security: By incinerating waste, ships can prevent the transmission of diseases across ports and countries [4].

Regulatory Framework

MARPOL Annex VI: Introduced regulations for shipboard incineration, stipulating that certain materials, like contaminated packaging materials and polychlorinated biphenyls (PCBs), cannot be incinerated onboard [5]. IMO Guidelines: The International Maritime Organization (IMO) has set forth guidelines on shipboard incineration operations, emphasizing the need for ships to maintain an Incinerator Log Book [6].

Best Practices and Considerations

- Pre-treatment: Waste should be sorted and, where necessary, pre-treated before incineration to ensure efficient burning.

- Regular Maintenance: Like all shipboard machinery, incinerators require regular maintenance to remain operational and efficient.

- Training: Crew should be adequately trained in the operation, maintenance, and safety protocols related to the incinerator.

- Energy Recovery: Some modern systems incorporate waste heat recovery mechanisms, utilizing the heat from incineration for other shipboard processes.

Commercial ship incinerators play a pivotal role in contemporary waste management practices at sea. As regulations continue to evolve and the maritime industry seeks greener operational practices, the importance of efficient and eco-friendly waste disposal methods, such as incineration, will only grow.