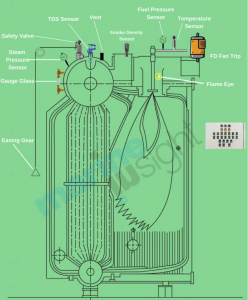

Safety valves are critical components of marine boilers, designed to prevent over-pressurization that could lead to catastrophic failures. These valves automatically release steam if the pressure exceeds safe levels, thus ensuring the safety of the boiler system and the vessel.

Safety valves are critical components of marine boilers, designed to prevent over-pressurization that could lead to catastrophic failures. These valves automatically release steam if the pressure exceeds safe levels, thus ensuring the safety of the boiler system and the vessel. According to SOLAS Chapter II-1 regulations, every steam boiler and unfired steam generator must be equipped with at least two safety valves to ensure adequate capacity for pressure relief.

Marine boilers require safety valves to ensure the safe operation of the boiler under varying pressure conditions. At least two safety valves must be fitted to each boiler to prevent over-pressurization. These valves can be placed within the same valve chest, which should be separate from other valve chests and connected to the boiler via a single neck. The minimum diameter for these valves is 38 mm, and the appropriate valve area can be determined using the following formula:

A×C=(9.81×H×E)/P

Where:

- H is the total heating surface in m².

- E is the evaporative rate in kg of steam per m² of heating surface per hour.

- P is the working pressure of the safety valves in MN/m² absolute.

- A is the aggregate area through the seating of the valves in mm².

- C is a discharge coefficient that varies by valve type (4.8 for ordinary, 7.2 for high lift, 9.6 for improved high lift, 19.2 for full lift, and 30 for full bore relay operated safety valves).

Types of Safety Valves

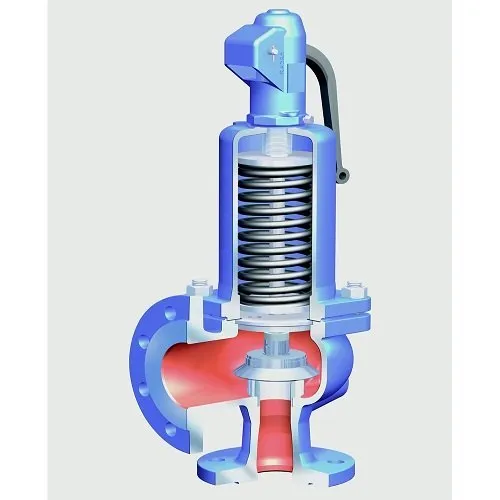

Marine boiler safety valves are crucial for preventing over-pressurization and ensuring safe operation. These valves can be broadly categorized into spring-loaded and pilot-operated safety valves, with further specific types based on their design and functionality.

i) Spring-loaded Safety Valves

These are the most common types of safety valves used in marine boilers. The valve is held closed by a spring, and it opens when the steam pressure exceeds the spring force.

- Ordinary Spring-loaded Safety Valve: Features a winged valve without a waste steam piston. Typical lift is approximately D/24.

- High-Lift Safety Valve: Includes a winged valve with a waste steam piston but no floating ring. Typical lift is approximately D/12.

- Improved High-Lift Safety Valve: Wingless valve with a waste steam piston and floating ring, designed to increase valve lift using waste steam pressure acting on a piston. Typical lift is approximately D/12. This design improves steam flow and reduces the risk of valve seizure.

ii) Pilot-operated Safety Valves

These use a pilot valve to control the main valve. The pilot valve opens at a lower pressure, allowing steam to act on the piston of the main valve, which then opens at the set pressure.

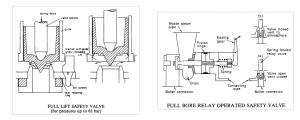

- Full Bore Safety Valve: Consists of main and pilot control valves directly communicating with boiler pressure. The main valve remains closed due to boiler pressure acting upon it. The pilot valve allows steam pressure to build up and act upon the operating piston attached to the main valve spindle, causing the main valve to open. It is suitable for high-pressure boilers, offering rapid closing to save steam.

- Full Lift Safety Valve: The valve moves up in the guide sleeve, preventing waste steam pressure from acting on top of the valve. A vent keeps the space between the valve disc and spindle guide at atmospheric pressure, allowing full flow conditions for escaping steam. Designed for pressures up to 63 bar, ensuring efficient operation under high-pressure conditions.

Easing Gear

Easing gear is another important feature associated with boiler safety valves. It allows for manual operation of the safety valve in cases where it fails to open automatically when the boiler is over-pressurized. This manual intervention can be crucial in preventing accidents. Easing gear also facilitates regular testing of the valves at sea to ensure they are functioning correctly. The gear is designed to achieve a maximum lift of D/4 of the safety valve (one-quarter of the diameter of the safety valve’s orifice), allowing for the effective release of excess pressure.

Credit: Marineinsight

Additional Considerations

Materials: Safety valves and their components must be constructed from non-corrodible metals to ensure longevity and reliable operation. Common materials include bronze, stainless steel, monel metal, and cast steel for valve chests.

Accumulation Pressure Test: Maritime classification societies require an accumulation pressure test to verify the discharge capacity of newly fitted safety valves. During the test, all boiler inlets and outlets must be closed, and the boiler fired at maximum rate to ensure pressure does not exceed 10% above the working pressure. This test should last no more than 15 minutes for cylindrical boilers and 7 minutes for water tube boilers, unless waived to prevent damage to superheaters or economizers.

Maintenance and Testing

Regular maintenance is crucial for ensuring the reliable operation of safety valves. This includes adhering to manufacturer specifications for clearances and dimensions, ensuring all parts are aligned and functional, and conducting sound checks for faults during disassembly and reassembly.. Safety valves, being mechanical devices, are subject to wear and tear, corrosion, and accumulation of deposits over time. Regular maintenance ensures that these valves remain in good working condition and can operate freely when needed. Maintenance activities typically include cleaning, inspecting for damage or wear, replacing worn parts, and ensuring that moving parts are lubricated.

Testing involves:

- Routine Inspections: Regular visual inspections to check for any signs of wear or damage.

- Bench Testing: Periodic removal and testing of the valve on a test bench to verify its opening pressure and closing performance.

- In-situ Testing: Testing the valve in place on the boiler to ensure it opens at the correct pressure.

Regular maintenance is crucial for the reliable operation of safety valves. Key maintenance activities include:

- Adhering to manufacturers’ specifications for clearances and dimensions.

- Ensuring all parts are in alignment and functional.

- Overhauling valves carefully to maintain proper order and function.

- Conducting sound checks for faults during disassembly and reassembly.

Regulations and Standards

Safety valves on marine boilers must comply with international regulations and standards. The International Maritime Organization (IMO) and the International Association of Classification Societies (IACS) provide guidelines for the design, installation, and maintenance of these valves. Key standards include:

- IMO Resolution A.467(XII): Guidelines for the performance and testing of safety valves for marine boilers.

- IACS Unified Requirements P2: Pressure relief systems for marine boilers and pressure vessels.

- SOLAS chapter II-1: regulations, every steam boiler and un-fired steam generator must be equipped with at least two safety valves to ensure adequate capacity for pressure relief.

Challenges and Innovations

Ensuring the reliable operation of safety valves in the harsh marine environment presents several challenges, including corrosion, scaling, and wear. Innovations in materials and design are helping to address these challenges. For instance, the use of corrosion-resistant alloys and advanced sealing materials has improved the longevity and performance of safety valves.

Safety valves are vital for the safe operation of marine boilers, protecting the vessel and its crew from the dangers of overpressure. Adhering to international standards and conducting regular maintenance and testing are essential practices for ensuring the reliability and effectiveness of these critical components. As technology advances, continuous improvements in materials and design will further enhance the safety and performance of marine boiler safety valves. By adhering to a schedule of regular maintenance, testing, and adjustment, ship operators can mitigate risks associated with boiler operations, comply with international safety standards, and ensure the longevity of the boiler system.

By Dr.Reza Karimpour

Here are seven open-ended questions based on the provided text about marine boiler safety valves, to evaluate yourselves:

- Why are safety valves critical components of marine boilers, and what potential risks do they mitigate?

- How do SOLAS Chapter II-1 regulations influence the installation of safety valves on steam boilers and unfired steam generators?

- Describe the formula used to determine the appropriate valve area for marine boiler safety valves and explain the significance of each variable.

- What are the differences between spring-loaded safety valves and pilot-operated safety valves, and what are the advantages of each type?

- Explain the role of easing gear in the operation and maintenance of boiler safety valves.

- What are the key considerations for the materials used in the construction of safety valves, and why are these materials chosen?

- Discuss the importance of regular maintenance and testing for marine boiler safety valves and describe the typical procedures involved.