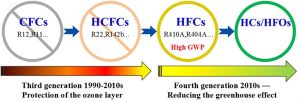

The maritime industry has long relied on various refrigerants to ensure the efficient operation of refrigeration and air conditioning systems on ships. In recent years, environmental regulations have increasingly influenced the choice of refrigerants, with a notable shift towards more environmentally friendly options. Hydrofluorocarbons (HFCs) have emerged as a popular choice due to their lower ozone depletion potential (ODP) compared to chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs). This article explores the family of HFC gases permitted for use on ships under the MARPOL Convention, detailing their characteristics, names, and applications in marine refrigeration and air conditioning systems.

Refrigeration systems are essential on ships for maintaining the quality of perishable goods and ensuring the comfort of personnel. The selection of an ideal refrigerant and the implementation of precise charging and leak detection methods are crucial for the efficiency and safety of these systems.

Characteristics of a Good/Ideal Refrigerant

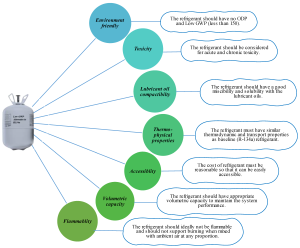

A good refrigerant for ship refrigeration systems should possess several critical characteristics:

- Environmental Friendliness: The refrigerant must have no Ozone Depletion Potential (ODP) and a low Global Warming Potential (GWP), ideally less than 150. This minimizes environmental impact, making the refrigerant more sustainable.

- Toxicity: It should be non-toxic to ensure the safety of the crew and passengers. Both acute and chronic toxicity must be considered.

- Flammability: The refrigerant should ideally be non-flammable and not support burning when mixed with ambient air, ensuring it does not pose a fire hazard.

- Thermo-physical Properties: It must have thermodynamic properties similar to the baseline refrigerant R-134a. This includes high latent heat of vaporization, low freezing point, and high critical temperature, which enhance efficiency and performance.

- Lubricant Oil Compatibility: The refrigerant should have good miscibility and solubility with the lubricant oils used in the system. This compatibility is crucial for maintaining the integrity and longevity of the refrigeration components.

- Volumetric Capacity: It should have appropriate volumetric capacity to maintain system performance, ensuring efficient cooling and heat transfer.

- Accessibility: The refrigerant should be reasonably priced and easily accessible, allowing for practical implementation and maintenance.

Regulatory Background: The MARPOL Convention

The International Convention for the Prevention of Pollution from Ships (MARPOL) is a key international maritime environmental treaty. It includes provisions aimed at minimizing pollution from ships, including air pollution. Annex VI of the MARPOL Convention, which deals with air pollution, addresses the control of emissions from shipboard refrigeration and air conditioning systems. The use of refrigerants with high global warming potential (GWP) is restricted, promoting the adoption of more sustainable alternatives.

HFC Gases Allowed Under MARPOL

HFCs are synthetic gases used as alternatives to ozone-depleting substances. While they do have a higher GWP compared to natural refrigerants like ammonia or carbon dioxide, they are widely used due to their favorable thermodynamic properties and safety profile. The following HFCs are commonly used in marine applications and are allowed under the MARPOL Convention:

| Refrigerant | Chemical Name | Characteristics | Applications | Systems Served |

|---|---|---|---|---|

| HFC-134a | 1,1,1,2-Tetrafluoroethane | Non-flammable, non-toxic, efficient in a wide range of temperatures | Marine air conditioning systems | Direct expansion (DX) systems |

| HFC-404A | Blend of HFC-125, HFC-143a, and HFC-134a | Low toxicity, low flammability, good energy efficiency | Commercial refrigeration systems | Low and medium temperature refrigeration systems |

| HFC-407C | Blend of HFC-32, HFC-125, and HFC-134a | Non-ozone depleting, properties similar to HCFC-22, suitable retrofit option | Air conditioning systems, refrigeration applications | Direct expansion air conditioning systems, retrofits from HCFC-22 systems |

| HFC-410A | Blend of HFC-32 and HFC-125 | High efficiency, non-ozone depleting, operates at higher pressures | Air conditioning systems | Split system air conditioners, heat pumps |

| HFC-507 | Blend of HFC-125 and HFC-143a | Excellent thermodynamic properties, non-flammable | Commercial refrigeration | Low and medium temperature refrigeration systems, transport, and storage of perishables |

Advantages and Challenges of HFCs in Marine Applications:

Advantages:

- Environmental Benefits: HFCs do not deplete the ozone layer, aligning with international environmental regulations.

- Safety: Many HFCs are non-flammable and have low toxicity, making them safe for use in confined ship environments.

- Efficiency: HFCs provide good energy efficiency, which is crucial for the operational costs and environmental impact of marine vessels.

Challenges:

- Global Warming Potential: While better than CFCs and HCFCs, HFCs still have a significant GWP. The maritime industry is continually seeking alternatives with even lower GWPs.

- Regulatory Pressure: Ongoing regulatory changes may further restrict HFC use, prompting the need for continued innovation and adaptation in marine refrigeration technologies.

Other Refrigerants Used on Ships

While HFCs are widely used, they are not the only refrigerants utilized in marine applications. Other refrigerants include:

Ammonia (R717) : High efficiency, zero ODP, and low GWP, but toxic and flammable. Used in industrial refrigeration systems, especially in larger vessels and fishing ships. Absorption refrigeration systems, large-scale refrigeration.

Carbon Dioxide (R744) : Zero ODP, very low GWP, operates at high pressures. Increasingly used in marine refrigeration and air conditioning systems. Transcritical and subcritical refrigeration systems.

Hydrocarbons (e.g., Propane R290, Isobutane R600a): Zero ODP, low GWP, but flammable. Used in smaller refrigeration units, it is increasingly considered for larger systems. Small refrigeration systems, some larger units with safety measures.

HFOs (Hydrofluoroolefins, e.g., R1234yf, R1234ze): Low GWP, non-ozone depleting, low flammability. Emerging alternatives to HFCs in both refrigeration and air conditioning. Newer systems designed for low GWP refrigerants and retrofits.

Instruments and Methods for Charging Refrigerants

Charging refrigerants into a ship’s refrigeration system requires precision and the right set of tools to ensure the system operates efficiently and safely. The following equipment and steps are commonly used:

- Manifold Gauge Set: This essential tool monitors the pressure of the refrigerant during the charging process. It includes high-pressure and low-pressure gauges connected to the refrigeration system.

- Vacuum Pump: Before charging, the system must be evacuated to remove air and moisture, which can cause inefficiencies and corrosion. The vacuum pump creates a vacuum in the system.

- Refrigerant Cylinder and Charging Scale: Refrigerants are stored in cylinders, and a charging scale measures the exact amount of refrigerant being added, ensuring the system is charged with the correct quantity.

- Refrigerant Identifier: This instrument checks the purity of the refrigerant, ensuring no contamination that could affect system performance.

Charging Procedure:

-

- Preparation: Ensure all safety measures are in place, and the correct type and amount of refrigerant are available.

- Evacuation: Use the vacuum pump to thoroughly evacuate the system.

- Charging: Connect the manifold gauge set, start the refrigeration system, and add refrigerant slowly, monitoring pressures and temperatures to ensure the system is correctly charged.

Detecting Refrigerant Leakages

Detecting refrigerant leaks promptly is crucial for maintaining system efficiency and preventing environmental harm. Several methods and instruments are used for this purpose:

- Electronic Leak Detectors: These devices detect refrigerant leaks by sensing the presence of refrigerant gases in the air. They are highly sensitive and can detect even small leaks.

- Ultrasonic Leak Detectors: These detectors pick up the sound of refrigerant escaping from the system, useful in noisy environments like ships.

- Soap Bubble Solution: Applying a soap solution to suspected leak areas produces bubbles if refrigerant is escaping. This is a simple and cost-effective method for pinpointing leak locations.

- Fluorescent Dyes: Adding a fluorescent dye to the refrigerant allows leaks to be identified using a UV light, effective for locating leaks that are not easily accessible.

- Pressure Testing: Pressurizing the system with nitrogen and monitoring for pressure drops can indicate the presence of leaks.

For refrigeration systems on ships, selecting an ideal refrigerant with optimal characteristics and employing precise charging and leak detection methods are crucial for ensuring system efficiency and environmental safety. By adhering to these practices, refrigeration systems can operate effectively, ensuring the safety and comfort of ship operations.

Very good and useful information, thank you

very good put up, i certainly love this website, keep on it