Learn about protective devices in marine diesel engines, their operation checks, and essential maintenance for safe shipboard engine operations.

Protective Devices in Marine Diesel Engines

Marine diesel engines are the beating hearts of merchant ships, driving propellers, generating power, and enabling global trade. Given the enormous loads and harsh operating environments, even minor abnormalities can lead to catastrophic failures, costly downtime, or dangerous situations onboard. To safeguard both the machinery and human life at sea, protective devices play a crucial role.

Protective devices are the critical safeguard system integral to every marine diesel engine, designed to prevent catastrophic damage and ensure uninterrupted operational safety. These sophisticated sensors and automatic shutdown mechanisms continuously monitor vital parameters like lubricating oil pressure, coolant temperature, overspeed, and exhaust gas temperatures. By providing immediate alerts and initiating automatic engine shutdown or slowdown before a critical fault occurs, these protective systems are fundamental for preventing expensive repairs, minimizing vessel downtime, and protecting the crew and asset. Investing in the maintenance and reliability of these devices is non-negotiable for maximizing engine lifespan, ensuring compliance with class regulations, and maintaining ultimate operational security at sea.

These devices act as the engine’s “senses” — continuously monitoring parameters such as lubricating oil pressure, cooling water temperature, and engine speed. When an abnormality is detected, they automatically trigger alarms, reduce engine load, or initiate shutdown procedures to prevent major damage.

By the end, you will gain a clear understanding of how these devices function, how seafarers test them in practice, and why systematic maintenance ensures safety and reliability at sea.

1. Understanding Protective Devices in Marine Diesel Engines

What Are Protective Devices?

A protective device is any system, switch, or mechanism designed to detect abnormal engine conditions and prevent escalation into serious damage or accidents. Unlike monitoring instruments, which only display values (such as gauges and meters), protective devices automatically act once a preset threshold is reached.

They are essentially the “last line of defense” for the engine.

Examples include:

- Lube oil low-pressure switch – detects loss of lubrication, which could cause bearing seizures.

- Jacket cooling water high-temperature switch – warns or stops engine if overheating occurs.

- Overspeed trip relay – cuts off fuel to prevent engine destruction during runaway.

- Electromagnetic solenoid valve & air piston – directly actuate the engine stop system when triggered.

Why Are They Essential?

The consequences of not having reliable protective devices are severe:

- Bearing failures from inadequate lubrication.

- Thermal stress from overheating cooling water.

- Explosions caused by uncontrolled overspeed.

- Environmental risks if engine failure leads to navigational accidents or oil spills.

Thus, IMO conventions (such as SOLAS) and classification societies (DNV, LR, ABS, etc.) require protective devices to be installed, tested, and maintained systematically.

2. Core Protective Devices Explained

Lube Oil Low-Pressure Switch

The lubrication system is vital for reducing friction and carrying away heat. If oil pressure falls below safe limits, metal-to-metal contact occurs.

- Operation principle: Pressure switch senses low oil pressure, sends an electrical signal to the solenoid valve, which then actuates the air piston to stop the engine.

- Testing method: Engineers simulate a pressure drop using a pressure drop gauge or by opening a test cock.

Jacket Cooling Water High-Temperature Switch

Cooling water prevents thermal stress in cylinder liners and heads. If its temperature rises beyond limits (typically 85–95°C for most engines), engine seizure may follow.

- Operation principle: The switch senses high temperature, initiating an alarm and possible shutdown.

- Testing method: Applied heat source (electric pot/heater) is used during operation check.

Overspeed Relay / Speed Sensor

Overspeed is one of the most dangerous failures, often caused by sudden load rejection, fuel rack sticking, or turbocharger faults.

- Operation principle: Speed relay monitors rpm; if it exceeds a set threshold (usually 10–15% above normal), it cuts fuel.

- Testing method: Engineers use a manual test switch or electronic simulator to confirm trip operation.

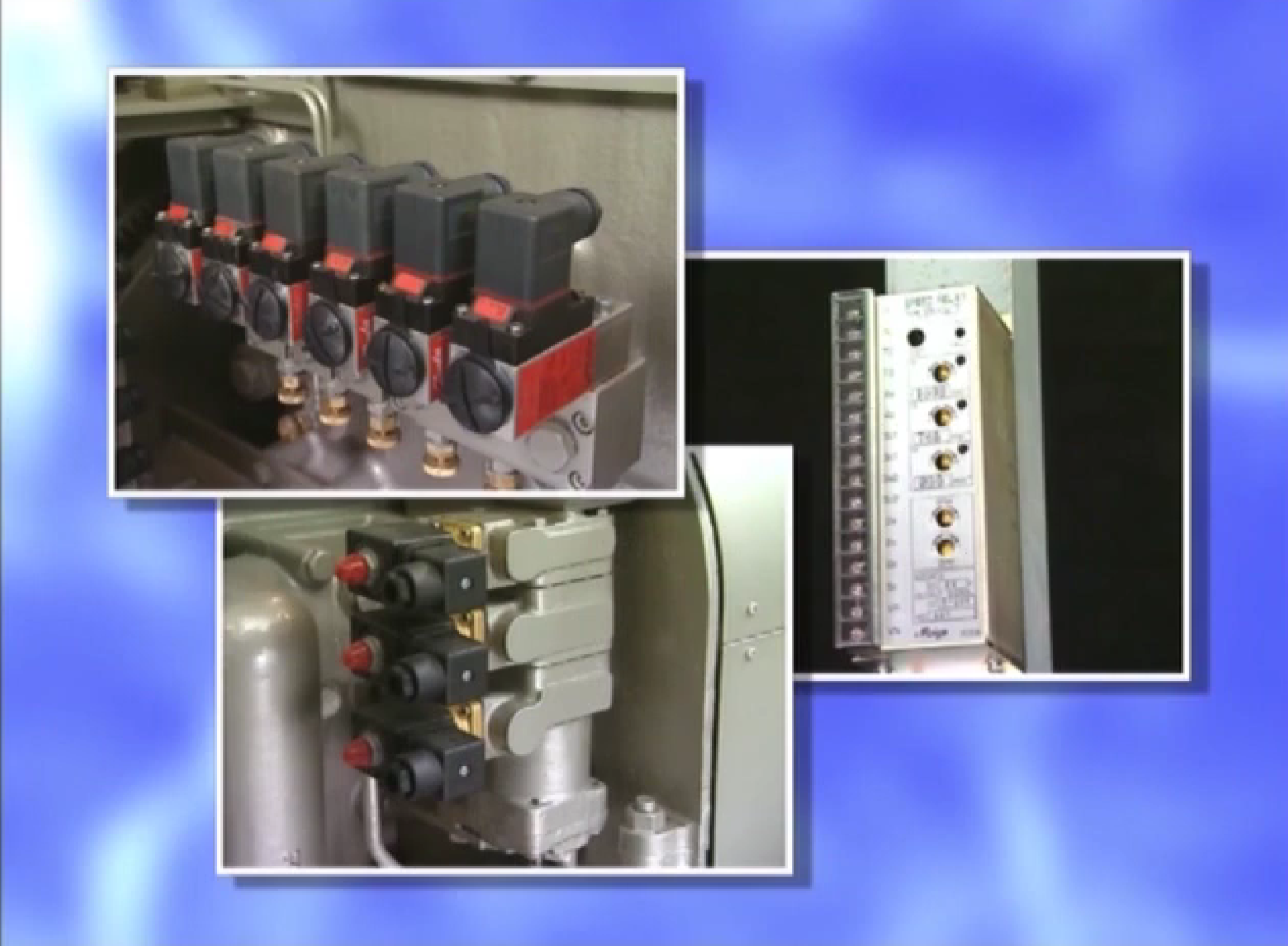

Engine Stop Mechanism (Air Piston & Solenoid Valve)

When abnormality is detected, the protective system ultimately activates the engine stop system:

- Air piston for stop: Pneumatically pushes fuel racks to zero position, halting fuel supply.

- Electromagnetic solenoid valve: Receives signal, vents control air, and triggers piston.

- Fuel limiting air piston: Restricts fuel injection if required.

This chain reaction ensures safe, controlled engine shutdown.

3. Operation Check of Protective Devices

The video provides a practical example of checking protective devices. Let’s expand on these standard practices:

Purpose of Operation Check

- Verifies that protective devices function correctly.

- Confirms trip points (set pressures, temperatures, or speeds).

- Ensures alarms and shutdowns activate in sequence.

Step-by-Step Operation Check

-

Preparation:

-

Inform the bridge and engine control room.

-

Ensure backup systems (standby generator, pumps) are available.

-

-

Testing Lube Oil Pressure Switch:

-

Slowly release lube oil pressure using a test cock or gauge.

-

Confirm alarm activation followed by engine stop via air piston.

-

-

Testing Cooling Water High-Temperature Switch:

-

Use a heating device (electric pot) to simulate high temperature.

-

Check alarm and stop sequence.

-

-

Testing Overspeed Trip Relay:

-

Operate test switch to simulate overspeed.

-

Ensure relay triggers solenoid valve and stops engine.

-

-

Final Confirmation:

-

Observe air piston activation.

-

Confirm fuel rack returns to zero.

-

Record test results in engine logbook.

-

4. Maintenance of Protective Devices

Why Maintenance Is Necessary

With time, mechanical wear, dust, oil contamination, and thermal cycling degrade protective devices. If not maintained, they may fail silently — providing false security until disaster strikes.

Air Piston for Stop – Maintenance Steps

As described in the video, the air piston assembly requires periodic overhaul:

-

Remove piston assembly from engine body.

-

Disassemble: separate fuel-limiting piston and stop piston.

-

Inspect O-rings for wear, hardening, or cracks.

-

Replace O-rings with new ones.

-

Apply grease on piston surfaces.

-

Reassemble in reverse order.

-

Test operation post-assembly.

General Maintenance Practices

-

Lubricate moving parts with suitable marine-grade grease.

-

Renew seals and O-rings periodically as per maker’s manual.

-

Check electrical connections of solenoid valves and relays.

-

Calibrate trip points with approved testing devices.

-

Follow PMS (Planned Maintenance System) intervals and manufacturer guidelines.

5. Regulatory Requirements and Standards

Protective devices are not optional; they are mandated under international maritime safety regulations.

IMO and SOLAS

-

SOLAS Chapter II-1 (Construction – Subdivision and Stability, Machinery, and Electrical Installations) requires essential machinery to have automatic shut-off and alarm systems.

-

Protective devices must be tested at sea trials and during surveys.

Classification Societies

-

DNV, ABS, LR, BV, and others publish rules requiring protective devices for main and auxiliary engines.

-

Annual and intermediate surveys include random checks of protective devices.

STCW and Crew Training

-

STCW Convention (Regulation III/1, III/2) requires engineers to understand engine protective systems.

-

Cadets are trained with simulators and actual test runs before certification.

6. Real-World Case Studies

Successful Prevention

A container ship experienced a sudden drop in lube oil pressure due to pump failure. The low-pressure switch tripped the engine before bearing damage occurred, saving weeks of repair and avoiding costly off-hire.

Failure to Maintain

On another vessel, neglected O-rings in the air piston stop assembly hardened and cracked. During an actual overspeed incident, the piston jammed, failing to cut fuel. The result: a destroyed cylinder head, four weeks in drydock, and millions of dollars in losses.

These examples highlight why routine testing and maintenance are non-negotiable.

7. Best Practices for Engineers

-

Conduct operation checks before departure and at regular intervals during voyages.

-

Always log test results with date, time, and responsible engineer’s signature.

-

Keep spare parts (O-rings, solenoid coils, seals) onboard.

-

During drydock, request class surveyor to witness protective device testing.

-

Encourage engine room drills for emergency shutdowns.

Conclusion

Protective devices in marine diesel engines are not just mechanical add-ons — they are guardians of safety, reliability, and compliance. From monitoring lube oil pressure to stopping overspeed, these systems give engineers the confidence to operate engines under extreme maritime conditions.

The video core content provided a valuable snapshot of how to check and maintain these systems. This article expanded on it with technical insights, regulatory context, and real-world lessons.

Ultimately, the effectiveness of protective devices depends on vigilant operation checks and disciplined maintenance routines carried out by trained seafarers. When done correctly, they not only safeguard machinery but also protect lives and the environment.

Thank youuu