Dual-fuel marine engines are increasingly being adopted in the maritime industry due to their flexibility, efficiency, and environmental benefits. These engines can operate using two different types of fuel—typically a combination of liquid fuels (like marine diesel oil) and gaseous fuels (such as natural gas). This capability allows ships to adapt to varying fuel availability and regulatory requirements while optimizing operational costs.

Key Features of Dual Fuel Engines

1. Fuel Flexibility

One of the most significant advantages of dual-fuel engines is their ability to switch between different fuel types. This flexibility enables vessels to utilize the most cost-effective or environmentally friendly fuel available at any given time. For instance, during certain voyages, a ship might use natural gas to reduce emissions while reverting to diesel when necessary.

2. Combustion Modes

Dual fuel engines typically operate in two modes:

- Diesel Mode: Similar to conventional diesel engines, where liquid fuel is injected and ignited by compression.

- Gas Mode: Where gaseous fuel is used, often resulting in lower emissions of nitrogen oxides and particulate matter compared to traditional fuels

Additionally, many dual-fuel engines can operate in a dual mode, utilizing both fuels simultaneously. This approach optimizes performance and minimizes emissions by adjusting the ratio of each fuel type based on operational needs

3. Environmental Impact

The environmental impact of dual-fuel engines is a crucial consideration in the maritime industry, particularly as global awareness of climate change and air pollution continues to grow. These engines are designed to operate more cleanly than traditional single-fuel engines, contributing to significant reductions in harmful emissions. Below are some key aspects of their environmental benefits:

- Reduction of Greenhouse Gas Emissions

Dual fuel engines, particularly those that utilize natural gas, can substantially lower greenhouse gas (GHG) emissions compared to conventional marine diesel engines. Natural gas is primarily composed of methane, which, when burned, produces less carbon dioxide (CO2) per unit of energy generated. Studies indicate that switching from heavy fuel oil (HFO) to natural gas can reduce CO2 emissions by up to 25%. This reduction is critical in the fight against climate change, as the shipping industry is a significant contributor to global GHG emissions.

- Lower Sulfur Oxides (SOx) Emissions

One of the most pressing environmental challenges for the maritime sector has been sulfur oxide emissions, which contribute to acid rain and have detrimental effects on human health and ecosystems. The International Maritime Organization (IMO) has implemented strict regulations limiting sulfur content in marine fuels. Dual-fuel engines that utilize natural gas produce virtually no SOx emissions, making them an attractive option for compliance with these regulations. This transition not only helps protect marine and coastal environments but also improves air quality in port cities.

- Reduced Particulate Matter (PM)

Particulate matter is another harmful pollutant associated with traditional marine fuels, leading to respiratory problems and other health issues for populations near shipping routes. Dual-fuel engines significantly reduce particulate matter emissions due to the cleaner combustion process associated with gaseous fuels. By minimizing PM emissions, these engines contribute to healthier air quality both at sea and in coastal communities.

- Nitrogen Oxides (NOx) Emissions Control

Nitrogen oxides are another group of pollutants that contribute to smog formation and respiratory problems. Dual fuel engines can achieve lower NOx emissions through optimized combustion processes. By operating primarily on natural gas, these engines can reduce NOx emissions by up to 80% compared to conventional diesel engines. This reduction is vital for meeting stringent NOx emission standards set by regulatory bodies.

Challenges in Implementation

While dual-fuel engines offer numerous advantages, their implementation and operation in the maritime industry come with a range of challenges. These challenges can affect installation, retrofitting, operation, maintenance, troubleshooting, and safety. Below is an overview of the key difficulties associated with dual-fuel engines in maritime applications.

1. Technical Complexity

Dual fuel engines require sophisticated systems to manage the different fuel types effectively. This includes:

- Integration of Systems: The need for specialized fuel storage tanks, supply systems, and safety equipment adds complexity to the vessel’s design and operation. Additionally, when using bio-LNG, which has different production processes compared to fossil LNG, there are specific requirements for handling and storage that must be considered.

- Skilled Workforce: Operators and crew must be highly trained to handle the complexities of dual fuel systems, which may not be part of standard maritime training programs. This requirement can lead to increased operational costs and training time. The workforce must also understand the nuances of bio-LNG, including its sourcing from sustainable biomass feedstocks and its implications on emissions reduction.

2. Infrastructure Limitations

The global infrastructure for alternative fuels, particularly liquefied natural gas (LNG) and hydrogen, is still developing:

- Bunkering Availability: Refueling options for alternative fuels are often limited to specific regions, restricting operational flexibility for vessels that rely on these fuels. While bio-LNG can utilize existing LNG bunkering infrastructure, the availability of bio-LNG specifically may still be limited in certain areas.

- Investment Needs: Developing a comprehensive bunkering network for dual fuel vessels requires significant investment and coordination among stakeholders, which can delay widespread adoption. The infrastructure must also be equipped to handle bio-LNG’s unique requirements while ensuring compatibility with fossil LNG systems.

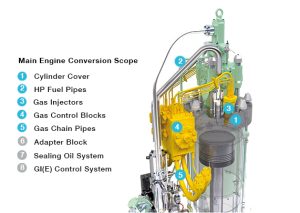

3. Retrofitting Challenges

Converting existing vessels to dual-fuel systems involves several hurdles:

- Downtime: Retrofitting requires significant downtime during which the vessel is out of service, affecting operational schedules and profitability.

- Cost Overruns: The complexity of retrofitting projects can lead to unexpected costs and delays due to labour availability and specialized components

- Limited Shipyard Capacity: Only a few shipyards are equipped to handle dual-fuel conversions, which may lead to capacity issues if demand surges

4. Operational Flexibility

While dual fuel systems provide operational flexibility by allowing switching between fuels based on availability and cost, this flexibility comes with its own set of challenges:

- Fuel Quality Control: Maintaining consistent fuel quality is essential for optimal engine performance. Variability in alternative fuels can lead to operational issues.

- Monitoring Systems: Advanced monitoring systems are necessary to ensure safe operation when switching between fuel types, adding another layer of complexity.

5. Safety Considerations

Safety is paramount when operating dual-fuel engines:

- Handling Gaseous Fuels: Gaseous fuels like LNG pose unique safety risks due to their flammability and potential for leaks. Proper handling protocols must be established to mitigate these risks.

- Emergency Procedures: Crew members must be trained in emergency response procedures specific to dual-fuel systems, which may differ from traditional single-fuel operations.

6. Economic Factors

The economic implications of adopting dual-fuel technology cannot be overlooked:

- High Initial Investment: The upfront costs associated with installing or retrofitting dual fuel systems can be substantial, which may deter some operators from making the transition.

- Fuel Price Volatility: The prices of alternative fuels like ammonia or methanol are currently higher than conventional marine fuels. Shipowners must ensure that charterers are willing to cover these increased costs before committing to retrofitting projects.

7. Regulatory Compliance

Navigating the regulatory landscape in the maritime industry presents several significant challenges. Compliance with environmental standards can differ widely across jurisdictions, leading to operational inconsistencies. This variation complicates the implementation of uniform practices and may require companies to adapt their operations based on local regulations, which can be resource-intensive and time-consuming. The International Maritime Organization (IMO) stipulates that a parent engine test of the same electronically controlled engine type is mandatory for a dual-fuel conversion to achieve NOx compliance. This requirement complicates retrofitting efforts and can delay projects if suitable test engines are not readily available, impacting timelines and operational efficiency. Additionally, compliance with the International Code of Safety for Ships using Gases or Other Low-flashpoint Fuels (IGF Code) introduces further complexities. The IGF Code sets forth safety standards for vessels using alternative fuels, necessitating rigorous adherence to safety management systems and operational protocols. This code aims to ensure that ships using low-flashpoint fuels operate safely, but it also requires ship operators to invest in specialized training and equipment to meet these standards effectively

Leading Dual Fuel Engine Manufacturers for Ships

The maritime industry has seen significant advancements in dual-fuel engine technology, with several manufacturers emerging as leaders in this sector. These companies are known for their innovative designs and commitment to environmental sustainability. Here are some of the top dual-fuel engine makers:

WinGD (Winterthur Gas & Diesel): WinGD is renowned for its X-DF series of dual-fuel engines, including the powerful 12X92DF model, which has been recognized as the world’s largest dual-fuel engine. WinGD’s engines are primarily used in large container ships and have gained popularity due to their efficiency and ability to operate on liquefied natural gas (LNG) as well as conventional fuels. The company has received numerous orders, highlighting its leadership in the dual fuel market.

MAN Energy Solutions: MAN Energy Solutions has developed the ME-LGIM engine, which operates on methanol and conventional fuels. This innovative engine has been ordered by major shipping companies, including A.P. Møller–Maersk, for their new container ships. MAN’s focus on alternative fuels positions it as a key player in the dual-fuel engine market

Wärtsilä: Wärtsilä offers a range of dual-fuel engines that can operate on LNG or conventional liquid marine fuels, including low-sulfur fuel oil (LFO) and heavy fuel oil (HFO). Their engines are designed for various vessel types, providing flexibility and compliance with stringent emission regulations.

Yanmar: Yanmar has developed dual fuel solutions that allow vessels to switch seamlessly between diesel and gas fuels. Their engines are designed to meet IMO NOx Tier III regulations and provide reliable performance across different operational conditions.

Mitsubishi Heavy Industries (MHI): MHI produces turbochargers for dual-fuel engines, particularly in collaboration with WinGD’s X-DF engines. Their technology enhances the performance and efficiency of these engines while meeting emission regulations.

Shipping Companies Utilizing Dual Fuel Engines

Several leading shipping companies have adopted dual fuel technology to enhance sustainability and comply with environmental regulations:

- Mediterranean Shipping Company (MSC): MSC has made significant investments in LNG dual-fuel vessels, with a large order book that includes new builds designed for both LNG and ammonia as future fuels. They aim to enhance sustainability while maintaining a modern fleet.

- COSCO: The Chinese shipping company has also opted for methanol dual-fuel ships, joining the trend of major carriers focusing on cleaner fuel alternatives.

- CMA CGM: This French shipping giant operates some of the largest LNG-powered container ships, utilizing WinGD’s X-DF engines for their ultra-large container vessels.

- A.P. Møller – Maersk: Maersk is integrating MAN’s methanol dual-fuel engines into its fleet, highlighting its commitment to reducing emissions and exploring alternative fuels.

- Hapag-Lloyd: This company has also invested in LNG-powered vessels, aligning with global efforts to minimize environmental impacts.

These companies are at the forefront of adopting dual fuel technology, reflecting a broader trend within the industry towards cleaner operations.

Best Simulators for Familiarization with Dual Fuel Engines

To effectively train personnel on the operation and management of dual-fuel engines, several simulators are available that provide realistic scenarios and hands-on experience:

Wärtsilä Simulator: Wärtsilä offers advanced simulation solutions that allow trainees to familiarize themselves with the operation of their dual-fuel engines in various scenarios, including emergency situations.

Kongsberg Maritime Simulators: Kongsberg provides comprehensive maritime simulators that include modules for dual-fuel engine operation, enabling users to practice managing different fuel types under various conditions.

Transas (part of Wärtsilä): Transas offers integrated simulation systems that cover a wide range of maritime operations, including specific training for dual fuel engine management.These simulators play a crucial role in preparing crew members for real-world challenges associated with operating dual-fuel engines, ensuring they have the necessary skills and knowledge to effectively manage these advanced systems.

Conclusion

The adoption of dual-fuel engines represents a significant advancement in maritime technology, offering a pathway toward more sustainable shipping practices. As the industry continues to evolve, understanding the operational mechanics and benefits of dual fuel systems will be essential for future maritime professionals, including students and cadets training for careers at sea. Emphasizing flexibility and environmental responsibility will be key themes as the maritime sector navigates its transition towards greener operations.