Introduction to Marine Steam Turbines

Marine steam turbines are engines that convert thermal energy from steam into mechanical work to propel ships. This technology has evolved significantly since its introduction in the late 19th century, offering efficiency and reliability for maritime transportation. Steam turbines work by expanding steam through a series of blades mounted on a shaft, which turns a propeller to move the ship. They are particularly favoured for their smooth operation, high power output, and efficiency at high speeds, making them suitable for large vessels like LNG carriers and naval ships. For more in-depth information, I recommend consulting specialized resources or the provided website links for specific details on designs, operations, and applications of marine steam turbines.

Marine steam turbines have revolutionized maritime propulsion since their inception in the early 20th century. Utilizing the principle of steam expansion, these turbines convert thermal energy into mechanical energy, providing efficient power for various ship types.

Marine steam turbines serve as a propulsion mechanism for ships, translating thermal energy from steam into mechanical energy to drive the ship’s propellers. This technology has been pivotal in the evolution of marine propulsion, offering significant advantages in terms of efficiency, especially for long voyages. While the use of marine steam turbines has seen fluctuations over the years, especially with the rise of diesel and gas turbine engines, they remain integral in specific segments of the maritime industry. Several types of ships continue to use marine steam turbines, including:

- LNG Carriers: Many liquefied natural gas (LNG) carriers use steam turbines powered by boilers heated by the gas that evaporates from the cargo. This design capitalizes on the availability of “boil-off” gas as a fuel, making steam turbines a preferred choice for some operators.

- Certain Tankers: Similar to LNG carriers, some tankers designed for transporting liquefied petroleum gas (LPG) or certain chemicals might use steam turbines.

- Naval Ships: Many navies around the world prefer steam turbines for their ships, including aircraft carriers, certain destroyers, and cruisers, due to their high power output, reliability, and the ability to use nuclear power as a heat source for the boilers.

- Some Cruise Ships and Icebreakers: A limited number of specialized ships, such as icebreakers and some cruise ships, might use steam turbines for propulsion due to their specific operational requirements.

Main Producers of Marine Steam Turbines

Marine steam turbines, which are critical components for the propulsion of various types of ships, including naval vessels, cargo ships, and some types of passenger ships, are produced by a number of companies around the world. The market for marine steam turbines is relatively specialized, with a few key players dominating the scene. As of my last update, the main producers globally include:

- General Electric (GE)

- Mitsubishi Heavy Industries (MHI)

- MAN Energy Solutions

- Rolls-Royce (now part of BAE Systems)

- Kawasaki Heavy Industries (KHI)

These companies are known for their technological innovation, global reach, and extensive experience in the marine industry. They continue to develop and refine marine steam turbines to meet evolving demands for efficiency, reliability, and environmental compliance in the maritime sector.

A Historical Shift from Marine Steam Turbines to Diesel Engines

Steam turbines revolutionized ship propulsion with their introduction in the late 19th century, offering advantages over traditional reciprocating engines such as smaller size, reduced maintenance, and lower vibration. Despite the need for precise reduction gears or turbo-electric transmission to match the high RPM of turbines to the effective propeller speeds, the benefits included lighter weight and more compact engine rooms.

The journey of steam turbine propulsion began with the Turbinia in 1894, showcasing direct drive but facing challenges in aligning the turbine’s efficient speed with the propeller’s. Innovations like cross-compounding and the introduction of high-pressure (HP), intermediate pressure (IP), and low-pressure (LP) turbines in series enhanced efficiency and power. RMS Queen Mary (1934) exemplified advanced applications with multiple turbines driving each shaft through reduction gearboxes.

The shift from marine steam turbines to marine diesel engines as the dominant mode of propulsion in commercial shipping over the last century was influenced by several key factors. These factors reflect the maritime industry’s ongoing pursuit of efficiency, reliability, and cost-effectiveness, alongside evolving regulatory and environmental standards. The main reasons for this shift include:

- Fuel Efficiency: Marine diesel engines are generally more fuel-efficient than steam turbines, especially at part load and varying power demands. This efficiency translates into lower fuel consumption for the same distance travelled or load transported, which is a critical factor given that fuel costs represent a significant portion of a vessel’s operational expenses.

- Operational Flexibility: Diesel engines can start and stop more quickly than steam turbine systems, which require time to raise steam. This operational flexibility is particularly advantageous for vessels that need to navigate through ports and congested waterways, where frequent adjustments to the engine’s power output are necessary.

- Lower Operational Costs: Beyond fuel efficiency, diesel engines tend to have lower operational costs in terms of crew requirements and maintenance. Steam turbine systems, especially those that are not integrated with gas turbines in combined cycle configurations, typically require more specialized knowledge for operation and maintenance, translating into higher staffing costs.

- Simpler Fuel Handling and Storage: Diesel fuel requires less complex handling and storage systems compared to the heavy fuel oil (HFO) and bunker fuel used in steam turbines. This simplicity can reduce the costs and logistical challenges associated with fuel management onboard.

- Advancements in Diesel Engine Technology: The development of high-efficiency, high-reliability diesel engines, including both medium-speed and low-speed versions, has made diesel propulsion increasingly attractive. Innovations in engine design, materials science, and fuel injection technologies have continually improved the performance and reduced the environmental impact of diesel engines.

- Environmental Regulations: The global push towards reducing emissions from ships has favored the adoption of marine diesel engines, which can be more easily adapted to meet stringent emissions standards. Technologies like selective catalytic reduction (SCR) and exhaust gas recirculation (EGR) have been more readily applied to diesel engines to reduce nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter emissions.

- Flexibility in Fuel Types: The development of diesel engines capable of running on a variety of fuels, including marine gas oil (MGO), low-sulfur fuels, and, more recently, liquefied natural gas (LNG), has provided additional flexibility in responding to changes in fuel availability and price, as well as environmental regulations.

While marine steam turbines continue to be used in certain applications where their specific advantages are pronounced (such as LNG carriers using boil-off gas), the overall trend has favoured diesel engines for most commercial shipping needs. The industry’s focus on operational efficiency, cost reduction, and environmental compliance has driven this shift and continues to influence the development of marine propulsion technologies.

Continued Applications of Marine Steam Turbines in Modern Shipping

Marine steam turbines, developed in the early 20th century, remain essential in modern shipping, particularly in nuclear naval ships, LNG carriers, and auxiliary vessels. They convert steam’s thermal energy into mechanical energy to power ships and generate onboard electricity, offering eco-friendly, efficient maritime operations. Despite the rise of gas turbines and diesel engines, steam turbines’ unique efficiency and adaptability for specific applications like nuclear propulsion highlight their continuing relevance in the industry.

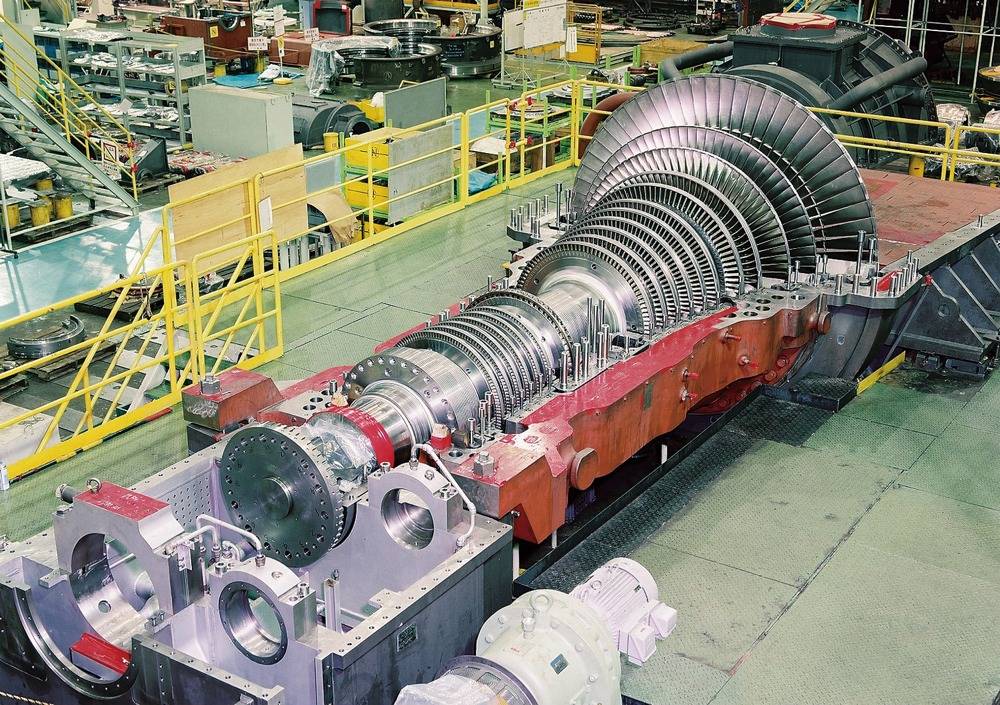

Key Components of the Turbine-Generator Systems

A typical marine steam turbine comprises critical components such as the turbine itself, a condenser, a boiler, and a feed pump, all crafted from robust materials like high-grade steel and titanium alloys. These materials are selected for their ability to withstand high temperatures and pressures while offering resistance to corrosion. Materials used in constructing marine steam turbines, such as advanced alloys and composites, are selected for their durability and ability to withstand the harsh maritime environment, ensuring longevity and reliability.

Operational Advantages and Suitability of Marine Steam Turbines

Marine steam turbines are prized for their operational efficiency, reliability, and ability to facilitate quiet and smooth operations. These attributes make them exceptionally suitable for large vessels that embark on extended voyages, such as container ships, oil tankers, and passenger liners. The introduction of ultra-steam turbines by Mitsubishi Heavy Industries has marked significant advancements, offering enhanced efficiency and reliability for the modern maritime industry, particularly for LNG carriers and container ships.

Efficiency and Fuel Consumption

While marine steam turbines offer high power output, they typically have higher specific fuel consumption compared to diesel engines. Adjustments in steam temperature control are crucial for optimizing their energy efficiency.

Automation, safety, and Control

Efficiency in marine steam turbines is significantly higher than that in traditional reciprocating engines. This efficiency is achieved through precise control systems involving throttle valves and governors that manage steam flow and maintain operational speed. Safety is paramount, with automatic overspeed trip mechanisms in place to prevent turbine damage under excessive speed conditions.

Automation and safety systems in marine steam turbines are critical for maintaining operational speed and safety, with mechanisms designed to prevent overspeed and other hazardous conditions.

Warming Up Procedures

Warming-up procedures are essential for ensuring that marine steam turbines operate within safe thermal and mechanical limits, preventing rapid temperature changes that could cause structural damage.

Maintenance and Challenges

Maintenance routines for steam turbines involve regular inspections and the cleaning of various components to ensure optimal function and safety. Despite their many advantages, marine steam turbines face operational challenges such as handling extreme conditions and managing wear. These challenges are mitigated through regular maintenance and advanced monitoring technologies. The maintenance of marine steam turbines involves regular inspections and the management of components exposed to high temperatures and pressures, which can present significant operational challenges.

Environmental Considerations and Future Directions

The maritime industry is under increasing pressure to adopt more sustainable practices. The commercial future of marine steam turbines depends on their adaptation to environmental regulations and fuel efficiency standards. Marine steam turbines and boilers are adapting to environmental pressures by enhancing fuel efficiency and adopting low-emission fuels like biofuels and synthetic fuels. These innovations aim to align turbine operations with sustainability goals, reducing NOx and SOx emissions. The integration of renewable energy sources and advanced control systems is expected to further minimize the environmental impact of these systems, maintaining their relevance in an increasingly eco-conscious maritime industry. Marine steam turbines emit lower levels of greenhouse gases compared to traditional marine engines but may contribute to NOx and SOx emissions. Their operation within LNG carriers and certain naval ships highlights their potential for environmentally-friendly propulsion when paired with cleaner energy sources.

The future of marine steam turbines lies in their ability to adapt to the evolving demands of the maritime industry. Despite environmental concerns, marine steam turbines are evolving to meet stricter sustainability standards. They’re enhancing fuel efficiency and incorporating low-emission fuels like biofuels and synthetic fuels to align with global emissions reduction mandates. Innovations such as integrating renewable energy sources and advanced control systems aim to minimize their environmental footprint. These adaptations ensure that marine steam turbines remain viable in a market shifting towards greener technologies. This evolution includes both technological advancements and operational improvements to meet the increasing demands for environmentally friendly maritime propulsion.

Marine steam turbines Vs gas turbines

Here are 14 questions, designed for students and engineers to assess their knowledge on this topic :

- What is the basic principle behind the operation of a marine steam turbine?

- A. Compression of steam

- B. Expansion of steam

- C. Condensation of steam

- D. Evaporation of water

- How are steam turbines used nowadays on board ships?

- A. as main propulsion

- B. as turbo-generator to produce electricity

- C. as turbo-pump, particularly in tanker ships for transferring crude oil cargo

- D. all of the answers are correct

- What are the challenge with the use of marine steam turbines (and boilers) as the main propulsion compared to marine diesel engines?

- A. The SFC is lower

- B. The SFC is zero

- C. The SFC is about the same

- D. The SFC is higher

- Why is the control of steam temperature crucial in the operation of a marine steam turbine?

- A. To increase fuel efficiency

- B. To minimize wear and tear

- C. To prevent overheating

- D. All of the above

- What role do condensers play in the efficiency of marine steam turbines?

- A. Increase steam pressure

- B. Decrease steam pressure

- C. Re-condense steam into water

- D. Generate extra steam

- Explore the environmental impact of utilizing steam turbines in marine settings.

- A. They emit lower greenhouse gases (mainly CO2) compared to traditional marine engines.

- B. They contribute to air pollution primarily through NOx and SOx emissions.

- C. They are generally benign to marine ecosystems when operated with clean energy sources.

- D. They require large amounts of freshwater resources.

- Compare and contrast the use of single-stage and multi-stage turbines in the maritime industry.

- Explain how the steam pressure affects the performance of a marine steam turbine.

- How do marine steam turbines compare to gas turbines in terms of efficiency and operational characteristics?

- What role does the automation and safety system play in the operation of marine steam turbines? Does it control turbine speed and activate emergency shutdown procedures?

- What technological innovations have been integrated into modern marine steam turbines to improve their performance?

- Predict future trends in the development of marine steam turbines and their impact on maritime engineering.

- List the key materials used in the construction of marine steam turbines and explain why these materials are chosen.

- What is the purpose of warming-up procedures in marine steam turbines, and what are the typical steps involved?

By Reza Karimpour

Very interesting article, thanks!