Marine diesel engines are the workhorses of the shipping industry, powering vessels ranging from small boats to massive container ships and tankers. These engines are designed to operate for extended periods of time, often in harsh environmental conditions, while producing reliable and efficient power.

In this article, we will explore the key features and components of marine diesel engines, as well as their operation and maintenance.

Marine Diesel Engines

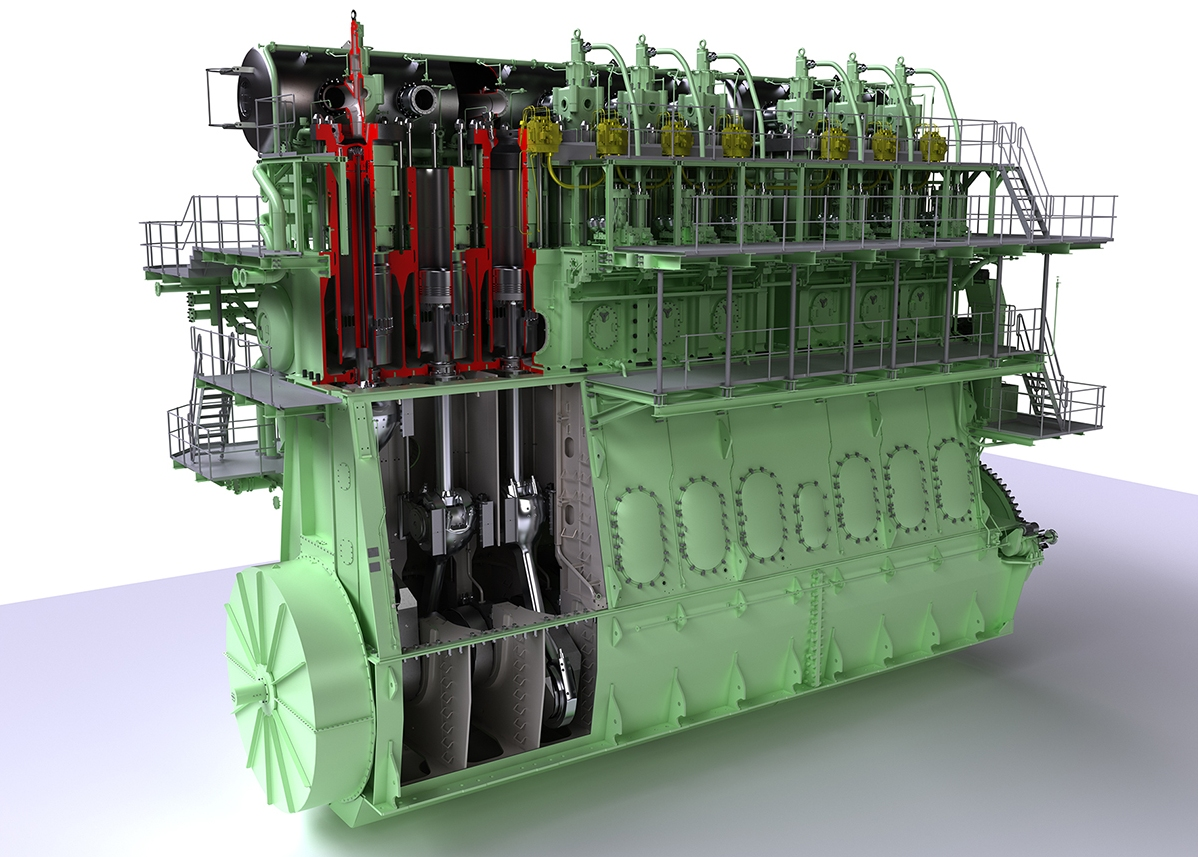

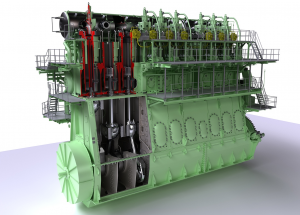

Design and Components

Marine diesel engines are designed specifically for the marine environment, with features that enable them to withstand the harsh conditions of the sea. The engines are typically large and heavy, with a sturdy construction that can withstand the vibration and shock of the vessel’s movement. The main components of a marine diesel engine include the cylinder block, pistons, connecting rods, crankshaft, camshaft, fuel injection system, cooling system, lubrication system, and exhaust system. The cylinder block is the main body of the engine, which houses the cylinders and other components. The pistons move up and down within the cylinders, driven by the connecting rods and crankshaft. The camshaft operates the engine’s valves, controlling the flow of air and fuel into the cylinders and the exhaust gases out of the engine. The fuel injection system injects fuel into the cylinders, mixing with air to create combustion. The cooling system keeps the engine’s temperature within a safe range, typically through the use of seawater or a separate cooling system. The lubrication system ensures that all moving parts are adequately lubricated, reducing wear and tear. The exhaust system removes the exhaust gases from the engine, typically through the use of a turbocharger and a system of pipes and mufflers.

Operation

Marine diesel engines operate on the principle of the diesel cycle, where air is compressed within the cylinder and then fuel is injected into the compressed air, creating combustion. The energy generated by combustion drives the pistons, which in turn drive the crankshaft, creating rotational energy that powers the vessel’s propeller. The engines are typically operated continuously for long periods of time, often requiring regular maintenance to ensure they operate at peak efficiency. The engines are controlled through a series of levers, switches, and gauges, which allow the operator to adjust the engine’s speed and monitor its performance.

Maintenance

Maintenance is essential for the reliable and efficient operation of marine diesel engines. Regular maintenance tasks include oil changes, filter replacements, and inspections of the engine’s components for wear and tear. In addition to regular maintenance, marine diesel engines may require repairs or replacements of components due to wear and tear or damage. These repairs may include rebuilding the engine’s cylinder head, replacing the fuel injection system, or repairing the cooling system.

Marine diesel engines are a crucial component of the shipping industry, providing reliable and efficient power for vessels of all sizes. Their robust construction, efficient operation, and ability to withstand harsh environmental conditions make them an essential part of modern shipping. However, the proper operation and maintenance of these engines are critical to their longevity and performance. Regular maintenance and repairs are necessary to ensure they continue to operate at peak efficiency, providing reliable power for the ships that depend on them.

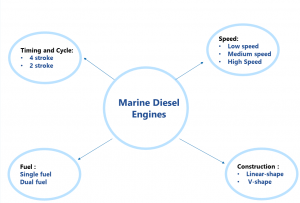

Marine diesel engines can be classified according to speed, timing and cycle, fuel type, and construction:

Two-stroke Marine Diesel Engines

Two-stroke marine diesel engines are commonly used in the shipping industry, particularly in large vessels such as tankers, container ships, and bulk carriers. These engines are known for their high power output, efficiency, and reliability.

Characteristics

Two-stroke marine diesel engines operate on the two-stroke cycle, where the engine completes a power cycle in two strokes of the piston. This is in contrast to four-stroke engines, which require four strokes of the piston to complete a power cycle. Two-stroke engines are typically lighter and more compact than four-stroke engines of similar power output, making them an attractive option for ship designers and builders. They also have a higher power-to-weight ratio, allowing them to produce more power for a given weight. Two-stroke engines use a system of ports in the cylinder liner to allow fresh air and exhaust gases to flow in and out of the cylinder. This eliminates the need for an overhead camshaft, which reduces the engine’s weight and complexity.

Advantages

One of the primary advantages of two-stroke marine diesel engines is their high power output. This makes them ideal for large vessels that require a significant amount of power to operate. Two-stroke engines are also known for their efficiency. Because they complete a power cycle in two strokes of the piston, they can generate power more frequently than four-stroke engines, which leads to less energy loss and higher efficiency. In addition, two-stroke engines are simpler in design and have fewer moving parts than four-stroke engines. This makes them easier to maintain and repair, as well as less expensive to produce.

Disadvantages

One of the primary disadvantages of two-stroke marine diesel engines is their high emissions of nitrogen oxides (NOx). This is due to the way the engines operate, with the ports in the cylinder liner allowing air to mix with fuel and combustion to occur. Efforts are being made to reduce these emissions through the use of exhaust gas recirculation (EGR) systems and selective catalytic reduction (SCR) systems. Two-stroke engines also require the use of a lubricating oil that is mixed with the fuel, which can lead to higher levels of particulate matter emissions. In addition, the engines require frequent maintenance, particularly of the air and fuel filters, to ensure they continue to operate efficiently.

In short, Two-stroke marine diesel engines are a popular choice for large vessels in the shipping industry due to their high power output, efficiency, and reliability. While they have some disadvantages, such as high emissions of NOx and the need for frequent maintenance, these issues are being addressed through the use of new technologies and improvements in design. As the shipping industry continues to evolve, two-stroke engines are likely to remain a critical component of the power systems used to drive these vessels.

Four-stroke Marine Diesel Engines

Four-stroke marine diesel engines are widely used in the shipping industry to power vessels of all sizes, from small boats to large container ships and tankers. These engines are known for their reliability, efficiency, and long service life.

Characteristics

Four-stroke marine diesel engines operate on the four-stroke cycle, which includes intake, compression, power, and exhaust strokes. This is in contrast to two-stroke engines, which complete a power cycle in two strokes of the piston. Four-stroke engines are typically heavier and more complex than two-stroke engines of similar power output, due to the additional components required to operate the engine. They also have a lower power-to-weight ratio, meaning they produce less power for a given weight. Four-stroke engines use an overhead camshaft to operate the engine’s valves, which allows for precise control over the engine’s operation. This can result in better fuel efficiency and lower emissions compared to two-stroke engines.

Advantages

One of the primary advantages of four-stroke marine diesel engines is their lower emissions of nitrogen oxides (NOx). This is due to the way the engine operates, with the use of an overhead camshaft allowing for more precise control over the engine’s operation. This can lead to better fuel efficiency and lower emissions. Four-stroke engines are also known for their durability and long service life. They require less maintenance than two-stroke engines and can last for many years with proper care and maintenance. In addition, four-stroke engines are more fuel-efficient than two-stroke engines at low speeds and partial loads, making them ideal for vessels that operate in these conditions.

Disadvantages

One of the primary disadvantages of four-stroke marine diesel engines is their higher weight and complexity. This can make them more expensive to produce and more challenging to maintain and repair. Four-stroke engines also have a lower power-to-weight ratio than two-stroke engines, meaning they produce less power for a given weight. This can be a disadvantage for vessels that require high power output, such as large container ships and tankers.

In short, Four-stroke marine diesel engines are a popular choice for vessels in the shipping industry due to their reliability, efficiency, and lower emissions compared to two-stroke engines. While they have some disadvantages, such as higher weight and complexity, these are often outweighed by their durability and long service life. As the shipping industry continues to evolve, four-stroke engines are likely to remain a critical component of the power systems used to drive these vessels.

There are several companies that produce marine diesel engines for the shipping industry, ranging from small engines for recreational boats to large engines for commercial vessels. Some of the major companies in this industry include:

- MAN Energy Solutions: MAN Energy Solutions produces a range of marine diesel engines, including both two-stroke and four-stroke engines, as well as dual-fuel engines that can operate on both diesel and natural gas.MAN B&W (Bergen & Wichmann) is a brand of marine diesel engines produced by MAN Energy Solutions, a leading manufacturer of diesel engines and power systems for marine, energy, and industrial applications.

- Wärtsilä Corporation: Wärtsilä produces a wide range of marine diesel engines, including both two-stroke and four-stroke engines, as well as engines that can operate on a range of fuels, including heavy fuel oil, marine diesel oil, and natural gas.Sulzer Marine Engines is a former subsidiary of Sulzer AG, a Swiss engineering and manufacturing company. The company produced a range of diesel engines for marine applications, including large two-stroke engines for commercial vessels and four-stroke engines for smaller vessels and auxiliary power.In 1997, Sulzer Marine Engines merged with Wärtsilä Corporation, a Finnish manufacturer of marine engines and power systems. The merged company, known as Wärtsilä-Sulzer, became one of the largest manufacturers of marine engines in the world, with a product range that included both two-stroke and four-stroke engines, as well as engines that could operate on natural gas or dual-fuel.

- Rolls-Royce Power Systems: Rolls-Royce Power Systems produces marine diesel engines under the MTU brand, which includes both two-stroke and four-stroke engines, as well as engines that can operate on natural gas or dual-fuel.

- Caterpillar Inc.: Caterpillar is a leading manufacturer of marine diesel engines, producing a range of engines for commercial vessels, workboats, and pleasure craft.

- Cummins Inc.: Cummins produces a range of marine diesel engines, including both two-stroke and four-stroke engines, as well as engines that can operate on a range of fuels, including diesel, natural gas, and biogas.

Other companies that produce marine diesel engines include Volvo Penta, Yanmar, Mitsubishi, and John Deere. These companies often provide additional services, such as installation, maintenance, and repair, to support their engines throughout their lifecycle.

Reference: www.maritimeducation.com