Marine diesel engines play a crucial role in powering ships and enabling global maritime trade. These engines are reliable, fuel-efficient, and have a long service life, making them the preferred choice for marine applications. This article delves into the intricacies of marine diesel engines on ships, discussing their history, operation, types, maintenance, and future developments.

History and Evolution of Marine Diesel Engines

1.1 Early Developments The development of marine diesel engines can be traced back to the late 19th century. The invention of the first diesel engine by Rudolf Diesel in 1893 paved the way for its marine applications. The first marine diesel engine was installed on a ship named Selandia in 1912, revolutionizing the shipping industry by providing a more efficient and reliable alternative to steam engines.

1.2 Advancements and Improvements Over the years, marine diesel engines have undergone significant improvements in terms of fuel efficiency, power output, and environmental impact. Advancements in fuel injection systems, turbocharging, and waste heat recovery have contributed to these enhancements. Today’s marine diesel engines are far more efficient and eco-friendly than their predecessors.

Operation and Working Principles

2.1 Basic Principles

Marine diesel engines work on the principle of internal combustion, converting the chemical energy stored in fuel into mechanical energy. They operate using a four-stroke cycle, which includes intake, compression, power, and exhaust strokes. Air is drawn into the cylinder during the intake stroke, compressed during the compression stroke, and fuel is injected and ignited during the power stroke, producing a high-pressure gas that drives the piston downward. Finally, the exhaust stroke expels the combustion products from the cylinder.

2.2 Components and Systems

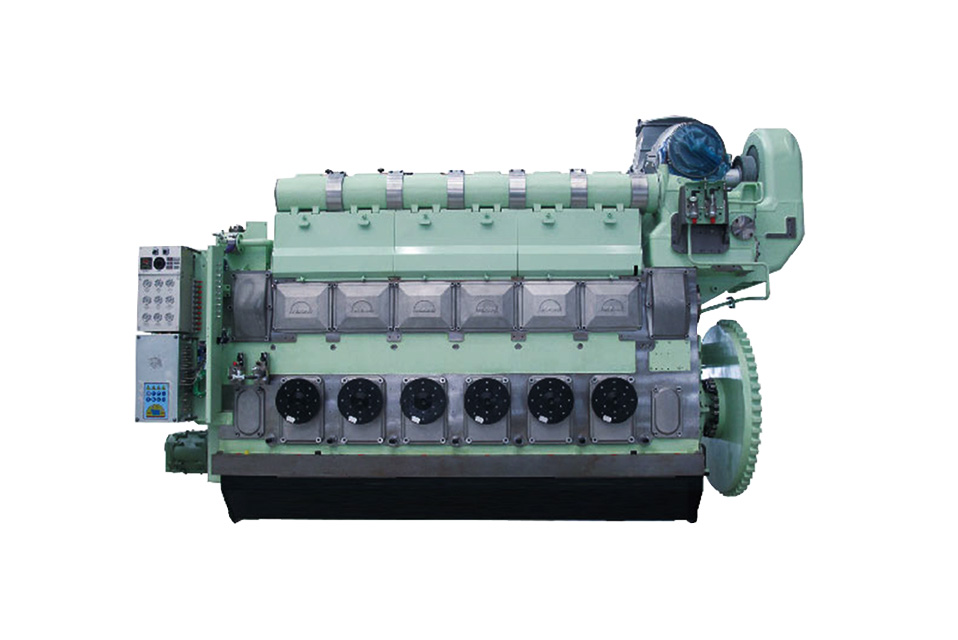

Key components of marine diesel engines include the crankshaft, connecting rods, pistons, cylinder liners, cylinder heads, fuel injection systems, turbochargers, and exhaust gas systems. These components work in tandem to ensure the efficient and reliable operation of the engine.

Types of Marine Diesel Engines

3.1 Two-Stroke Engines

Two-stroke marine diesel engines are predominantly used in large ships due to their high power output and fuel efficiency. In two-stroke engines, the power and exhaust strokes are combined, reducing the number of strokes per cycle. These engines are usually slow-speed and directly coupled to the ship’s propeller.

3.2 Four-Stroke Engines

Four-stroke marine diesel engines are more common in smaller ships and auxiliary applications. They are more versatile and can operate at higher speeds, making them suitable for generator sets and propulsion systems that require gear reduction.

3.3 Dual-Fuel Engines

Dual-fuel marine diesel engines can run on both diesel and liquefied natural gas (LNG) fuels. These engines have gained popularity due to their lower emissions and operational flexibility, particularly in environmentally sensitive areas.

Maintenance and Troubleshooting

4.1 Preventive Maintenance

Routine maintenance is essential for the optimal performance and longevity of marine diesel engines. Key maintenance tasks include oil and filter changes, cooling system maintenance, fuel system maintenance, and inspection of wear-prone components such as pistons, cylinder liners, and bearings.

4.2 Troubleshooting

Common issues that may arise in marine diesel engines include excessive fuel consumption, loss of power, abnormal noises, and overheating. Timely identification and resolution of these issues are crucial for maintaining the engine’s operational efficiency and avoiding costly downtime.

Future Developments and Challenges

5.1 Green Technologies

As environmental regulations become more stringent, the development of greener marine diesel engine technologies is essential. These include exhaust gas cleaning systems, selective catalytic reduction systems,”, write more in detail about Chapter 2: Operation and Working Principles

2.1 Basic Principles

Marine diesel engines work on the principle of internal combustion, converting the chemical energy stored in fuel into mechanical energy. They operate using a four-stroke cycle, which includes intake, compression, power, and exhaust strokes. Air is drawn into the cylinder during the intake stroke, compressed during the compression stroke, and fuel is injected and ignited during the power stroke, producing a high-pressure gas that drives the piston downward. Finally, the exhaust stroke expels the combustion products from the cylinder.

There is definately a lot to find out about this subject.

I like all of the points you have made.

Wow, that’s what I was looking for, what a information!

present here at this website, thanks admin of this website.