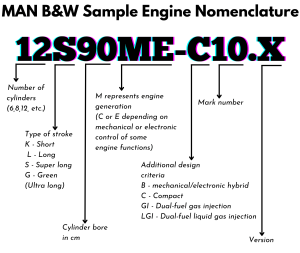

Marine two-stroke slow-speed diesel engines, particularly those from the MAN B&W series, have played a pivotal role in maritime propulsion systems. Known for their efficiency, reliability, and adaptability to various fuel types, these engines are a cornerstone of modern shipping. This article explores the evolution, operational principles, and advancements of MAN B&W two-stroke engines, highlighting their significance in the maritime industry.

Evolution of MAN B&W Diesel Engines

The history of MAN B&W diesel engines dates back to the early 20th century when diesel technology began to gain prominence in marine applications. MAN Diesel, originally part of the Burmeister & Wain (B&W) shipyard in Denmark, has been at the forefront of developing large-bore diesel engines since acquiring B&W in 1980. This acquisition allowed MAN to leverage B&W’s expertise in engine design and manufacturing, leading to significant advancements in two-stroke engine technology.In the 1990s, MAN B&W introduced its MC series of two-stroke engines, which set new standards for efficiency and performance. The MC series featured innovations such as improved turbocharging systems and optimized combustion processes that enhanced fuel efficiency while reducing emissions. By 2000, these engines had captured over 70% of the market share for large marine diesel engines, reflecting their widespread acceptance and reliability.The introduction of the ME-C engine series marked a significant advancement in the early 2000s. The ME-C engines incorporated electronic control systems that allowed for precise fuel injection and improved combustion management. This innovation not only increased efficiency but also provided flexibility for future fuel adaptations, including the capability to run on alternative fuels such as LNG (liquefied natural gas) and methanol.

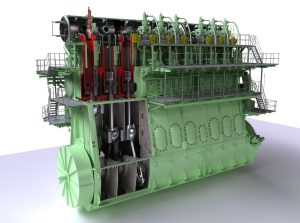

Key Components and Design Features

MAN B&W two-stroke engines are characterized by several key components that contribute to their operational efficiency:

- Cylinder Block: The robust cylinder block houses multiple cylinders where combustion occurs. The design is optimized for strength and thermal management, ensuring durability under high-stress conditions.

- Piston and Connecting Rod: The pistons are designed to withstand high pressures generated during combustion. They convert thermal energy into mechanical energy, driving the ship’s propeller through a connecting rod linked to the crankshaft.

- Turbocharger: A critical component that enhances engine performance by using exhaust gases to drive a turbine, increasing air intake for more efficient combustion.

- Fuel Injection System: MAN B&W engines utilize advanced direct fuel injection systems that allow for precise control over fuel delivery. This feature is crucial for optimizing combustion efficiency and minimizing emissions.

- Scavenging Ports: These ports facilitate the entry of fresh air into the cylinder while expelling exhaust gases during operation. The design ensures effective scavenging, which is vital for maintaining engine performance.

- Lubrication System: A well-designed lubrication system minimizes friction between moving parts, ensuring smooth operation and prolonging engine life.

Operational Principles

The operational cycle of a two-stroke diesel engine is a finely tuned process that maximizes efficiency and power output. Each stage of the cycle plays a critical role in ensuring optimal performance, particularly in marine applications where reliability and fuel efficiency are paramount. Below, we delve deeper into each stage of the operational cycle, highlighting the mechanics and significance of each phase.

1-Scavenging

The scavenging phase is crucial for preparing the cylinder for the next combustion cycle. As the piston descends during its power stroke, it uncovers scavenging ports located in the cylinder wall. This action allows fresh air to enter the cylinder while simultaneously pushing out exhaust gases from the previous cycle.The effectiveness of scavenging is enhanced by the design of the engine’s ports and the timing of their opening and closing relative to the piston movement. In modern MAN B&W engines, advanced port designs ensure that a maximum volume of fresh air enters while minimizing the loss of unburned fuel. This process is vital for maintaining engine efficiency, as it prevents residual exhaust gases from contaminating the fresh air-fuel mixture, which could lead to incomplete combustion and increased emissions.Additionally, turbocharging plays a significant role during this phase. The turbocharger uses exhaust gases to drive a turbine that compresses incoming air, increasing its density and allowing more air to enter the cylinder. This increased airflow enhances combustion efficiency and power output, making it particularly beneficial for large vessels that require significant thrust.

2-Compression

Once scavenging is complete, and the piston reaches bottom dead center (BDC), it begins its ascent in what is known as the compression stroke. During this phase, the piston compresses the air within the cylinder to extremely high pressures—often exceeding 30 bar (435 psi)—and temperatures that can reach up to 600°C (1,112°F).This high level of compression is essential for achieving ignition without the need for spark plugs, which are not used in diesel engines. Instead, as the piston approaches top dead center (TDC), the temperature of the compressed air becomes sufficient to ignite any fuel injected into the cylinder. The efficiency of this process relies heavily on precise control over both timing and pressure.In MAN B&W engines, advanced electronic control systems monitor various parameters such as engine load and temperature to optimize compression ratios dynamically. This adaptability ensures that engines operate efficiently under varying conditions, further enhancing fuel economy and reducing emissions.

3-Power Stroke

The power stroke begins just before TDC when fuel is injected into the highly compressed air within the cylinder. The precise timing of this injection is critical; it must occur at an optimal moment to ensure that combustion occurs effectively as the piston reaches TDC.Upon injection, fuel mixes with hot compressed air and ignites almost instantaneously due to the high temperatures. The rapid expansion of gases resulting from combustion generates significant pressure within the cylinder, forcing the piston downward with immense force. This downward movement converts thermal energy into mechanical energy, which is transmitted through connecting rods to turn the crankshaft and ultimately drive the ship’s propeller.The power stroke in two-stroke engines is particularly advantageous because it occurs once every revolution of the crankshaft (as opposed to every two revolutions in four-stroke engines), allowing for greater power output relative to engine size. This characteristic makes two-stroke engines ideal for large vessels where space and weight are critical considerations.

4-Exhaust Phase

Following the power stroke, as the piston moves back down toward BDC, it uncovers exhaust ports located near the bottom of the cylinder. This action allows spent gases from combustion to exit while simultaneously facilitating fresh air intake for the next cycle.Effective exhaust management is crucial for maintaining engine performance and efficiency. If exhaust gases are not expelled quickly enough, they can interfere with incoming fresh air during scavenging, leading to reduced combustion efficiency and increased emissions.In MAN B&W engines, careful engineering ensures that exhaust ports open at precisely timed intervals relative to piston movement. Additionally, some models incorporate advanced exhaust gas recirculation (EGR) systems that help manage emissions by redirecting a portion of exhaust gases back into the combustion chamber for re-burn. This process not only reduces harmful emissions but also enhances overall thermal efficiency.

In short, the operational cycle of a two-stroke diesel engine involves several stages that work together to maximize efficiency:

- Scavenging: As the piston descends during its power stroke, it uncovers scavenging ports that allow fresh air to enter the cylinder while simultaneously pushing out exhaust gases from the previous cycle.

- Compression: After reaching bottom dead center (BDC), the piston ascends, compressing the air within the cylinder to high pressures and temperatures necessary for ignition.

- Power Stroke: Near top dead center (TDC), fuel is injected into the highly compressed air. The resulting combustion forces the piston downward, generating power that drives the ship’s propeller.

- Exhaust Phase: Following the power stroke, as the piston moves down again, it uncovers exhaust ports that allow spent gases to exit while fresh air enters for the next cycle.

This efficient cycle enables two-stroke engines to produce high torque at low speeds—ideal for large vessels requiring substantial power without excessive fuel consumption.

Advances in Technology

Recent advancements in MAN B&W two-stroke engines focus on improving efficiency and reducing emissions:

Dual-Fuel Capabilities: The ME-C series can be retrofitted to operate on alternative fuels such as LNG or methanol. This flexibility allows ship operators to adapt to changing regulations and fuel prices while minimizing environmental impact.

Electronic Control Systems: The integration of advanced electronic control systems enhances operational efficiency by optimizing fuel injection timing and pressure based on real-time load conditions.

Modular Design: The modular design of ME-C engines simplifies maintenance and retrofitting processes. Components can be easily replaced or upgraded without extensive downtime or modifications to the vessel’s structure.

Emissions Reduction Technologies: MAN B&W has been proactive in developing technologies that comply with stringent international regulations regarding emissions. These include improvements in combustion processes that reduce nitrogen oxides (NOx) and sulfur oxides (SOx) emissions.

Environmental Considerations : As global awareness regarding environmental sustainability increases, so does scrutiny on marine emissions from ships powered by conventional fuels. MAN B&W has responded by developing dual-fuel options within their two-stroke lineup capable of meeting IMO Tier III standards for emissions reduction. These innovations allow vessels to switch between traditional fuels and cleaner alternatives without compromising performance or reliability.

–

Case Studies

The application of MAN B&W two-stroke engines can be seen in various large vessels across different sectors:

- Container Ships: Vessels like those operated by Maersk utilize models such as the 12K98MC engine, which delivers over 75,000 kW (approximately 101,000 hp). These powerful engines enable container ships to maintain high speeds while optimizing fuel usage over long distances.

- Bulk Carriers: The versatility of MAN B&W engines is evident in bulk carriers where low-speed operation is crucial for efficient cargo transport across oceans. Engines like the 6S50MC have proven effective in these applications due to their high torque output at lower RPMs.

- Tankers: In tanker operations where heavy loads are common, MAN B&W two-stroke engines provide reliable propulsion while maintaining low specific fuel consumption rates—often around 171 g/kWh at optimal loads.

Maintenance Practices

To ensure optimal performance and longevity of marine two-stroke diesel engines, regular maintenance practices are critical:

- Routine Inspections: Regular checks on lubricating oil levels, coolant systems, and fuel filters help prevent issues before they escalate.

- Turbocharger Maintenance: Given its role in enhancing efficiency, maintaining clean and functional turbochargers is essential.

- Fuel System Checks: Regularly inspecting injectors and ensuring proper fuel quality can prevent performance degradation.

- Exhaust System Maintenance: Keeping exhaust systems clear from blockages ensures efficient operation and compliance with emission standards.

Marine two-stroke slow-speed diesel engines from MAN B&W represent a significant advancement in maritime propulsion technology. Their evolution reflects continuous improvements in efficiency, reliability, and adaptability to changing environmental regulations. As global shipping faces increasing pressure to reduce emissions and improve sustainability practices, these engines will continue to play a crucial role in powering large vessels while meeting regulatory demands.With ongoing advancements in technology—such as dual-fuel capabilities and electronic control systems—MAN B&W two-stroke engines are well-positioned to meet future challenges in maritime operations while maintaining their reputation as leaders in marine propulsion solutions. Understanding their design principles and operational characteristics not only enhances operational efficiency but also contributes significantly to environmental stewardship within maritime operations.