Explore essential maintenance procedures for the lubricating oil system in marine diesel engine generators. Learn how to inspect, clean, and optimize components for engine reliability and regulatory compliance.

Why Lubricating Oil System Maintenance Matters in Maritime Operations

The lubricating oil system in a marine diesel engine generator plays a critical role in ensuring smooth, efficient, and safe engine operation. This system reduces friction, removes heat, cleans internal components, and protects the engine from wear and corrosion. Poor maintenance of this system can result in high oil contamination, mechanical failure, or even catastrophic engine damage at sea.

In the world of shipping, where delays can cost tens of thousands of dollars per day, and safety is non-negotiable, mastering lube oil maintenance isn’t optional—it’s fundamental.

Understanding the Lube Oil System: Basic Structure

A marine diesel generator’s lubricating system includes the following main components:

- Sump tank

- Settling tank (if installed)

- Purifier and heater

- Lube oil pump

- Cooler and thermostatic valve

- Strainers and filters

- Bypass centrifugal strainer

These parts work together to circulate, clean, and regulate oil properties. Some systems are designed with automated backwashing filters, while others rely on manual cleaning processes.

Lube Oil Cleaning Methods and Daily Management

1. Purifier Operation and Sludge Discharge

- Select the purifier using gravity board settings based on the purifier operation manual.

- Sludge discharge interval depends on the quantity of insoluble content in the oil.

- Inspect the bowl regularly and adjust discharge timing to prevent overflow or degradation.

2. Batch and Continuous Cleaning Techniques

- In batch cleaning, used oil is collected and processed before being re-used. The replacement schedule depends on oil dirt levels in the sump tank.

- In continuous overflow cleaning, oil is continuously purified using a dedicated tank, keeping contamination levels stable during engine operation.

Example Process: Transfer oil from Generator No.2 to the settling tank, allow cleaned oil to refill the generator, and then send the used oil for reprocessing. Ensure the oil circulates through the purifier at least 20 times for effective cleaning.

3. No Settling Tank? Use Direct Purifier Connection

In systems without a settling tank:

- Connect the sump tank directly to the purifier.

- Ensure inlet and return points are well-separated to avoid short circulation.

Monitoring Oil Properties and Engine Health

1. Regular Oil Analysis

Analyze lube oil properties every 500 running hours to detect:

- Viscosity breakdown

- Water or fuel contamination

- Metal particles indicating internal wear

2. Checking Oil Temperature and Pressure

During engine operation, monitor:

- Temperature (usually 90–95°C)

- Pressure (as specified by engine maker)

Deviations from set values can indicate:

- Blocked filters

- Pump failure

- Thermostatic valve malfunction

Adjustment Procedures: Pressure and Temperature Controls

Adjusting Lube Oil Pressure:

- Remove cap nut and loosen lock nut.

- Adjust pressure using the regulating screw.

- Tighten lock nut and re-fit cap nut.

Adjusting Lube Oil Temperature:

- Remove cap nut.

- Measure and adjust thermostat valve bolt position.

- Tighten all components securely after adjustment.

Weekly Maintenance: Centrifugal Bypass Strainer

This strainer reduces contamination during engine operation.

Cleaning Procedure:

- Close inlet valve.

- Remove cover and rotor assembly.

- Disassemble rotor, clean sludge inside walls (must be <10 mm thick).

- Clean nozzle, replace O-rings.

- Reassemble and ensure smooth rotor movement.

Tip: Insert paper lining to simplify future sludge removal. See image below.

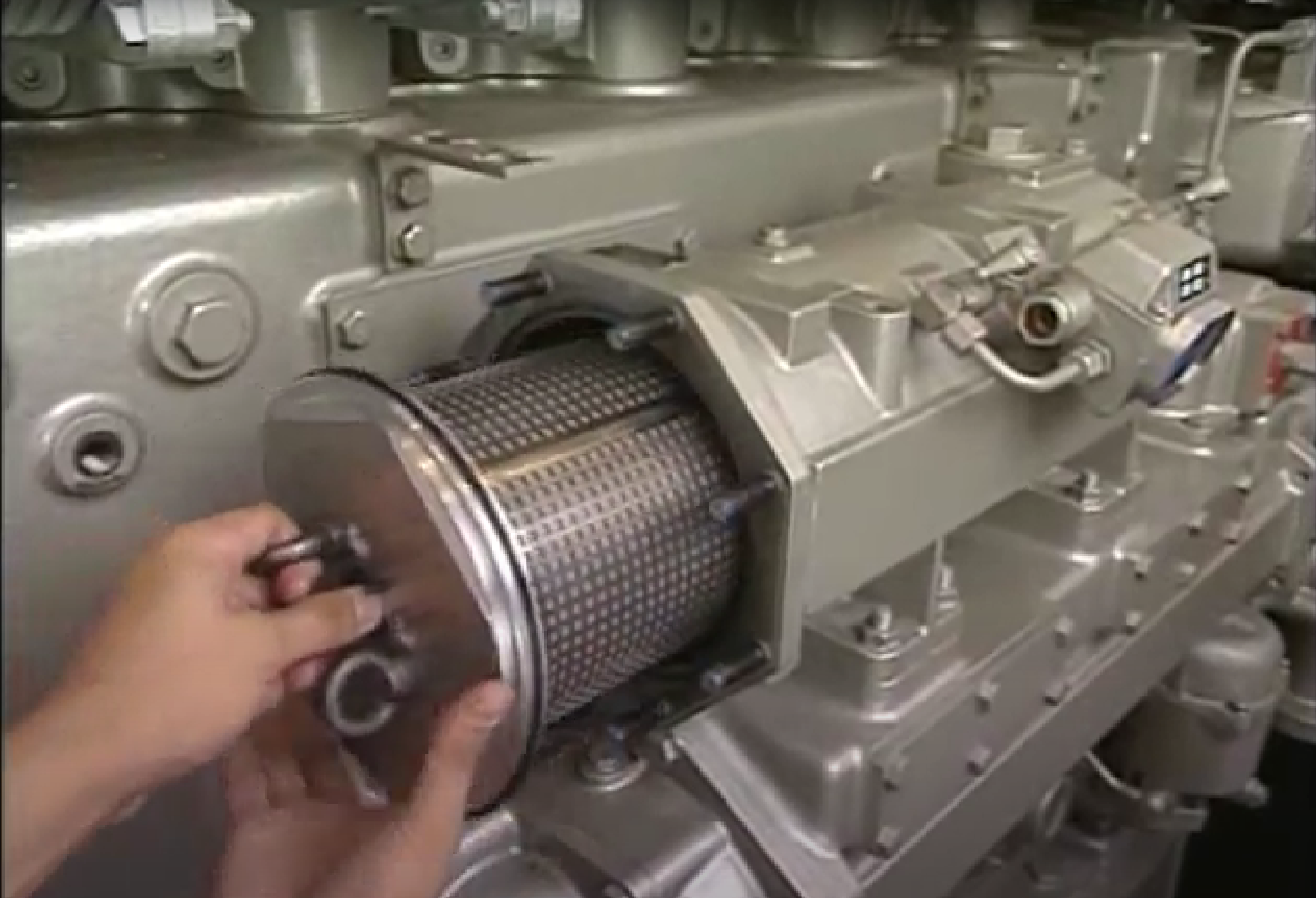

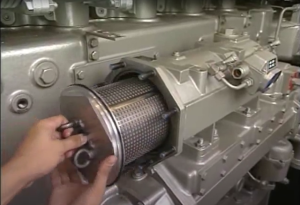

Maintenance of the Automatic Backwashing Filter

Many modern engines feature this type of filter for continuous self-cleaning.

Operating Principle:

- Oil flows from inside to outside through the strainer element.

- A turbine, driven by oil pressure, rotates a cleaning nozzle.

- Dirt is dislodged and discharged while filtration continues.

Daily Checks:

- Revolution indicator (confirm rotation is normal)

- Differential pressure gauge (if red zone appears, cleaning needed)

Cleaning Procedure:

- Drain filter.

- Remove cover, filter element, and gear.

- Soak strainer in cleaning fluid for 24 hours.

- Clean with high-pressure hot water or compressed air.

- Visually inspect for damage, replace worn elements.

- Reassemble with new O-rings.

Ensure gears re-engage properly during reassembly. See image below.

Real-World Example: Avoiding Engine Failure Through Proper Lube Oil Maintenance

In 2021, a bulk carrier in the Indian Ocean experienced an engine trip caused by low lube oil pressure. Investigation revealed that the bypass strainer hadn’t been cleaned in over three weeks, and sludge blocked the flow. The crew had skipped scheduled cleaning to meet tight deadlines.

Result: Forced shutdown, loss of propulsion, and a two-day delay for emergency repairs. Estimated cost: over USD 60,000.

Lesson: Even with automated systems, manual checks and cleaning remain vital.

FAQ: Common Questions on Lube Oil System Maintenance

1. How often should lube oil be changed? Refer to manufacturer recommendations, but typically after oil analysis every 500–1000 hours.

2. Can I reuse cleaned lube oil? Yes, if properly purified and tested for contaminants.

3. What is the difference between a bypass strainer and a main filter? The main filter runs continuously; the bypass strainer offers extra protection by filtering a portion of the oil to remove fine particles.

4. Why is the lube oil purifier temperature set at 90–95°C? At this range, oil viscosity is optimal for separating sludge and water.

5. How do I detect lube oil system failure early? Watch for sudden drops in pressure, unusual noises, rising engine temperatures, or red indicators on the filter.

Conclusion

Lube oil system maintenance is not just another checklist item. It is one of the most cost-effective ways to protect marine diesel engines from damage, improve operational reliability, and comply with safety standards.

Whether you’re managing a container ship or operating a tugboat, understanding how to clean strainers, monitor indicators, adjust valves, and analyze oil is essential. As technology advances, the human role in observation and intervention continues to be critical.

References

- MAN Energy Solutions. (2023). Marine Diesel Engine Lube Systems. https://www.man-es.com

- Wärtsilä. (2024). Lube Oil Purification and Monitoring. https://www.wartsila.com

- IACS. (2023). Machinery Maintenance Guidelines. https://www.iacs.org.uk

- DNV. (2023). Technical Advisory: Marine Engine Lubrication. https://www.dnv.com

- Alfa Laval. (2022). Centrifugal Oil Cleaning Systems. https://www.alfalaval.com

- IMO. (2022). Engine Room Safety Guidelines. https://www.imo.org