Discover in depth how a ship’s main propulsion system works—from the main engine and shafting to thrust bearings, seals, and propellers. This guide blends rigorous technical insight with clear, accessible language for maritime students, engineers, and enthusiasts alike.

Propelling a ship across the world’s oceans is no small feat. The journey from burning fuel to pushing water backward (and thus nudging the vessel forward) involves a carefully integrated chain of machinery, control, and engineering finesse. In this article, we’ll walk through the heart of that chain: the Main Propulsion System.

From giant two-stroke engines to seals, shafts, propellers, and control systems — you’ll gain a structured, human-readable view of how modern ships convert combustion into thrust. Along the way, we’ll explore recent innovations, real-world examples, and common questions.

Why the Main Propulsion System Matters in Modern Maritime Operations

Every cargo ship, tanker, LNG carrier, bulk carrier, or cruise liner depends on its main propulsion as the heartbeat of movement. Poor design, maintenance lapses, or inefficiency here can translate to:

- Massive fuel waste (fuel is one of the largest operating costs)

- Higher emissions (impacting compliance with IMO, EU, etc.)

- Downtime or failures at sea — with serious safety, schedule, and financial consequences

- Lower competitiveness in a decarbonizing industry

Meanwhile, international and regional regulations are pushing rules on emissions and energy efficiency. The propulsion system is under growing scrutiny as the core lever for decarbonization.

In short: if the propulsion system is not optimized, the whole vessel’s performance, sustainability, and economics suffer. That’s why every naval architect, marine engineer, and stakeholder must understand it deeply.

The Architecture of the Main Propulsion System: An Overview

At a high level, the main propulsion chain consists of:

-

Main Engine (ME)

-

Reduction Gearbox (if needed)

-

Shafting System (intermediate shaft, thrust shaft, tail shaft)

-

Thrust Bearing

-

Stern Tube & Seals

-

Propeller Assembly (FPP or CPP)

-

Turning Gear

-

Air Starting System

-

Lubrication System

-

Cooling System

-

Fuel System

-

Exhaust System

In the following sections, we’ll unpack each component, explain how it fits, and share real-world notes and trends.

Main Engine (ME)

Types & Basic Principles

In modern merchant vessels, the main engine is most often a two-stroke, slow-speed marine diesel engine from leading makers like MAN, WinGD, or Wärtsilä. These engines typically run at roughly 80–120 rpm. Because that speed closely matches efficient propeller rotation speeds, they can often be directly coupled to the shaft without needing a gearbox.

Alternatively, a medium-speed four-stroke engine (around 250–800 rpm) may be used — especially where size, layout, or other constraints favor a more compact installation. In that case, a reduction gearbox is required to step down RPM for the propeller.

High-speed engines (e.g., >1,000 rpm) are uncommon for large ships and mostly used on smaller vessels, where weight and installation constraints differ.

From energy supply to mechanical output, the main engine is the centerpiece.

Key Subsystems and Mechanics

-

Cylinder & Piston System: Combustion chamber, piston rings, liner, cylinder head, and cooling passages.

-

Camshaft, Timing Gear & Valve System: For scavenging, exhaust, and admission.

-

Turbocharging & Scavenging: Exhaust gas turbochargers supply pressurized air for combustion and scavenging.

-

Reversing Mechanism: Many slow-speed two-strokes can reverse rotation.

-

Safety & Control Systems: Instrumentation, control valves, overspeed protection, load sensors, and automation.

Real-World Example

Ultra-large container ships show how main engines blend with energy-recovery, hybridization, and efficiency systems. For instance, waste-heat recovery can produce steam that powers a turbine and provides additional electric output — helping lower fuel consumption and emissions.

Advantages & Constraints

Pros of slow-speed 2-stroke MEs:

-

High thermal and fuel efficiency

-

Fewer moving parts relative to high-speed engines

-

Direct coupling possibility (no gearbox)

Challenges:

-

Larger size and weight

-

Rigid installation and structural demands

-

Requires robust starting systems (often compressed air)

-

Must handle pulsating combustion loads

In contrast, medium-speed engines can be more compact, but require a gearbox, more cylinders, and often have lower fuel efficiency per unit power.

Emerging Trends & Innovations

Over the past few years, the industry has been actively working to decarbonize propulsion. Notable directions include:

-

Dual-fuel engines (e.g., methanol, hydrogen, ammonia) gaining approvals in principle from classification societies.

-

Hybridization / electric assist — main engines supplemented by electric motors or batteries for load sharing and flexibility.

-

Advanced control & optimization — precise fuel injection, variable turbocharging, AI-based fuel optimization, and route/trim optimization.

These directions reflect regulatory pressure, market demand, and technological maturity.

Reduction Gearbox (if medium-speed engine is used)

When a medium-speed engine is chosen, the crankshaft speed typically exceeds the optimal propeller speed by a factor of about 3–8. Without intervention, this mismatch leads to inefficiencies, cavitation, structural stress, and noise.

Hence, the reduction gearbox steps down RPM while multiplying torque. Key points:

-

Gear arrangement: Single-stage, multi-stage, epicyclic, double-input, cross-connect, etc.

-

Clutches and couplings: Allow disengagement, load sharing, or cross connections (e.g., in CODAG or multi-engine setups).

-

Lubrication, cooling & load balancing: Gearboxes run under high load and require robust oil lubrication, temperature monitoring, and maintenance.

-

Reverse gear (if needed): Some gearboxes include reverse capability (though many marine engines are reversible in themselves).

While gearboxes add cost, weight, maintenance, and some losses, they are indispensable in many designs when a medium-speed engine is used.

Shafting System: Intermediate, Thrust & Tail Shafts

Between the gearbox (or directly from the engine) and the propeller lies the shafting assembly — the central mechanical path transmitting torque and rotation to the propeller.

Components & Layout

-

Intermediate Shaft: Used to bridge distance or accommodate alignment constraints; there may be multiple sections.

-

Thrust Shaft: Delivers the thrust load into the hull via the thrust bearing.

-

Tail Shaft: The final segment right before the propeller.

Each shaft segment is supported by bearings and must be precisely aligned to minimize vibration, wear, and power loss.

Design Considerations

-

Materials: High-tensile alloy steels, with liners or claddings to resist corrosion and wear.

-

Diameter & stiffness: Sizing accounts for bending, torsional resonance, vibration modes, and critical speeds.

-

Shaft seals & couplings: Flexible couplings may absorb misalignments or damp vibrations.

-

Alignment & tolerances: Precise alignment ensures longevity and reduces losses.

The shafting system is usually “invisible” to the ship’s crew — but any misalignment or damage here is expensive and risky.

Thrust Bearing

Pushing a ship through water means pushing back on something — and that “something” is the ship’s hull via the thrust bearing.

Purpose & Principle

A thrust bearing sits between the thrust shaft and the ship’s hull structure. It receives the axial force generated by the propeller and transfers it into the ship’s structure, preventing the shaft from shifting.

Types & Design

-

Collar (sliding) thrust bearings

-

Tilting pad thrust bearings — multi-pad designs allow dynamic load redistribution and lower wear.

-

Hydrodynamic film: A thin oil film separates sliding surfaces, carrying load while minimizing friction.

-

Monitoring & condition sensors: Temperature sensors, oil film thickness, vibration monitoring.

A failure in the thrust bearing can be catastrophic — leading to shaft displacement, propeller misalignment, and even hull damage.

Stern Tube & Seals

After the tail shaft exits the hull, it passes through the stern tube — a cylindrical enclosure through which the shaft rotates and penetrates the hull. Stern tube systems house the shaft, allow for lubrication, and maintain hull integrity.

Key Elements

-

Stern tube liner with corrosion/wear-resistant surfaces

-

Journal bearings inside the tube for radial support

-

Seals at the hull penetration to prevent seawater ingress and lubricant egress (lip, labyrinth, mechanical/face seals)

-

Lubrication & flushing: Oil or water-lubricated arrangements; flushing for cleanliness and cooling

-

Pressure compensation to reduce seal load and leakage risk

Proper sealing is vital: a leak can flood the engine room, and oil loss can starve bearings.

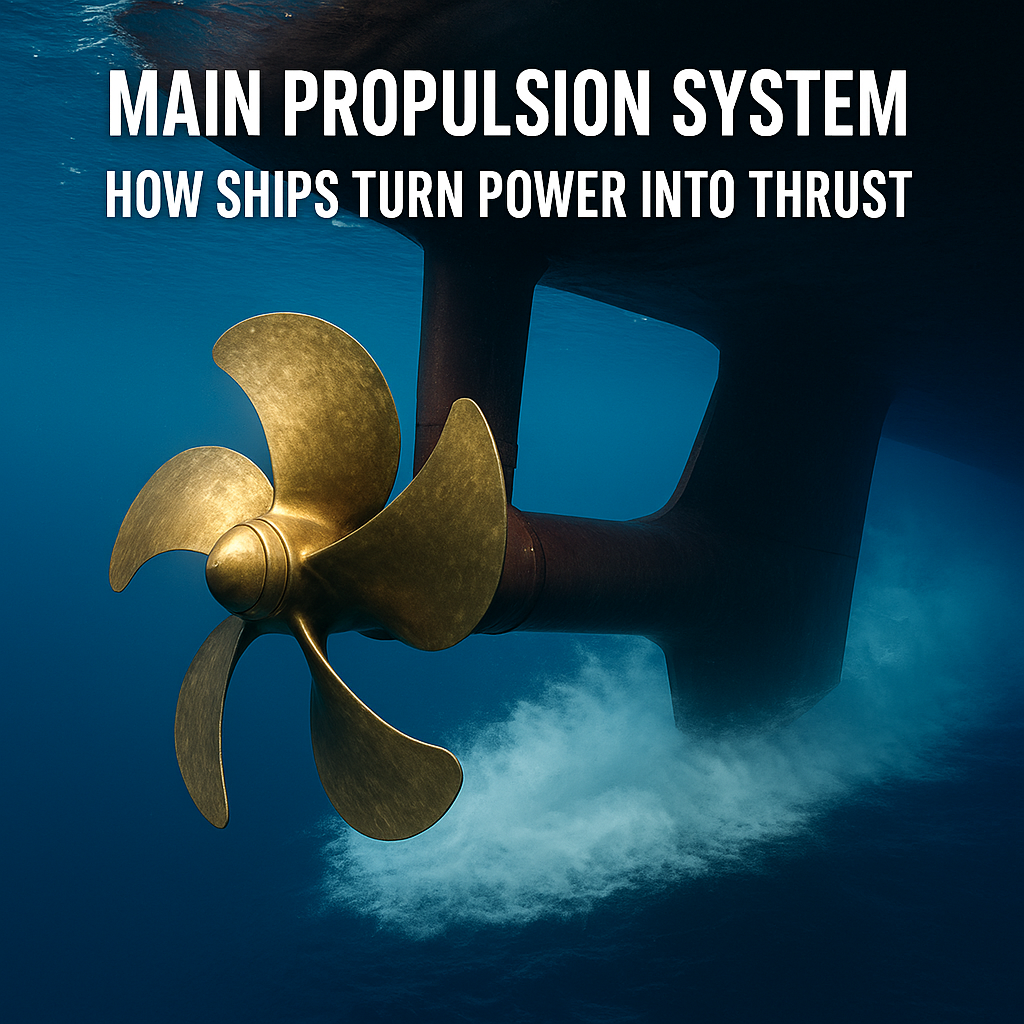

Propeller Assembly: Fixed-Pitch & Controllable-Pitch Propellers

At the end of the chain is the propeller — the device converting torque into thrust by pushing water backward.

Fixed-Pitch Propeller (FPP)

-

Simple and robust design

-

Blades fixed at a set pitch

-

Efficient at one design condition (e.g., cruising speed)

-

Common in bulk carriers, tankers, and cargo ships

Controllable-Pitch Propeller (CPP)

-

Blade pitch adjustable via hydraulic or mechanical actuators while turning

-

Flexible operation: reverse thrust, fine speed adjustment, better maneuverability

-

Suited to vessels with variable speed profiles (offshore vessels, ferries)

With a CPP, constant RPM can yield different thrust by altering pitch. With FPP, the engine or gearbox must change RPM or direction for thrust variation or reversal.

Design & Optimization

Propellers are designed with hull form, load patterns, cavitation margins, noise criteria, and efficiency curves in mind. Modern optimization blends CFD, empirical methods, and algorithmic search to derive shapes that balance efficiency, cavitation performance, and noise.

Real-World Note

Ice-class vessels often pair CPPs with robust gearboxes, hydrodynamic couplings, and flywheels to survive torque spikes from ice impacts while maintaining maneuverability.

Turning Gear

The turning gear (or turning machine) slowly rotates the main shaft — and thus the engine and propeller — at very low speed during port stays or maintenance.

Its purposes:

-

Prevent local cooling or thermal gradients in long idle periods

-

Help with alignment, inspection, or balancing

-

Facilitate maintenance or gearbox lubrication

Typically, electric or hydraulic motors drive the turning gear. It must be disengaged before main engine operation.

Air Starting System

Large marine engines need more than an electric starter. The air starting system provides high-pressure compressed air to each cylinder to initiate rotation.

Components & Operation

-

Air receivers store compressed air at high pressure

-

Starting valves admit air into cylinders to drive pistons down

-

Distributor / manifold manages sequence and timing

-

Check valves & safety devices prevent backflow and overpressure

-

Compressors keep the system charged

Controlled blasts of compressed air spin the engine until fuel injection and ignition take over. Reliability is critical, so the system is safeguarded and often redundant.

Main Engine Lubrication System

The lubrication oil (LO) system ensures bearings, pistons, cams, liners, and other moving parts receive proper oil film thickness under all loads.

Typical Components & Flow

-

LO pumps (main, standby, emergency)

-

Filters / purifiers (centrifuges, strainers, duplex filters)

-

Coolers / heat exchangers

-

Distribution manifolds

-

Pressure control & relief valves

-

Branch lines to components

-

Sump / drain return

-

Monitoring: Pressure, temperature, flow, contamination

Challenges & Considerations

-

Oil cleanliness and additive life

-

Viscosity control with temperature

-

Water ingress and combustion by-products

-

Cylinder lubrication strategies and feed rates

-

Redundancy and safe bypass arrangements

Failures or blockages in the LO system can lead to bearing damage or catastrophic engine failure.

Main Engine Cooling System

Combustion and friction generate significant heat. The cooling system is a multi-loop arrangement carefully managing thermal energy removal.

Typical Cooling Circuits

-

Jacket Water for engine block and cylinder head

-

Piston Cooling (oil or water)

-

Fresh Water / Sea Water Heat Exchanger loop dumping heat to seawater or a secondary cooler

-

Scavenge Air / Turbocharger Cooling

-

Charge Air Cooling / Aftercooling

Temperature control, flow rates, corrosion, fouling, and redundancy are critical. Proper thermal balance protects components and sustains efficiency.

Main Engine Fuel System

Fuel is conditioned, filtered, heated, and precisely metered before injection.

Key Components & Flow

-

Storage and day tanks

-

Transfer and booster pumps

-

Filters and separators to remove water and sediment

-

Fuel heaters to set viscosity and improve atomization

-

High-pressure pumps and injectors (or common-rail units)

-

Instrumentation: Flow meters, pressure/temperature sensors, and control valves

Modern engines demand precise injection timing, pressure, and atomization for efficiency, emissions control, and reliability.

Main Engine Exhaust System

After combustion, exhaust gases exit through a carefully designed path that manages heat, flow, emissions, and noise.

Elements of the Exhaust System

-

Turbochargers to recover energy and boost intake pressure

-

Exhaust piping and silencers

-

Bypasses & valves for special load conditions

-

Emission control: SCR, EGR, scrubbers, particulate filters

-

Insulation & expansion joints for thermal management

The aim is to minimize back pressure, maximize heat recovery where used, and meet emission and noise limits.

Integrating It All: System Interplay & Control

While each subsystem is vital, the art is integrating them into a reliable, efficient, and maintainable whole. This means:

-

Sophisticated control (engine control modules, distributed control systems)

-

Safety interlocks, alarms, redundancies

-

Holistic design balancing thermal, mechanical, fluid, and structural domains

-

Monitoring, instrumentation, diagnostics, and data analytics

A good analogy: building a car is easy; making a car that reliably drives uphill in varying climates, handles failures, conforms to emissions, and runs for decades? That’s the engineering challenge of marine propulsion — multiplied in size, risk, and cost.

Case Studies & Real-World Applications

Ice-Class Diesel-Mechanical

Medium-speed engines coupled through reduction gearboxes to CPPs are common in ice-capable vessels. Hydrodynamic couplings, flywheels, and robust control logic help manage torque spikes during ice interaction while preserving maneuverability and safety margins.

Diesel-Electric in Harsh Environments

In polar and offshore environments, diesel-electric arrangements feeding azimuth thrusters provide excellent torque control, redundancy, and maneuverability. This architecture separates prime movers from the propulsor line, offering flexible machinery layouts and improved survivability.

Ultra-Large Container Vessel Efficiency

Waste-heat recovery, optimized turbocharging, and advanced common-rail injection are widely used on ultra-large container ships to lower specific fuel oil consumption and reduce emissions while maintaining high service speeds.

These cases show how propulsion architecture adapts to application and environment.

Recent Innovations in Main Propulsion (Past 3–5 Years)

-

Dual-Fuel & Alternative Fuel Engines

Growing portfolios of methanol-, ammonia-, and hydrogen-capable engines, often with class approvals in principle, reflect rapid fuel diversification. Pilot projects are expanding from coastal pilots to deep-sea demonstrations. -

Hybrid & Electric Assist Propulsion

Diesel-electric systems, shaft generators/motors, energy storage, and PTO/PTI configurations provide flexible load sharing, peak shaving, and improved part-load efficiency. -

Pod & Azimuth Propulsors

New podded and azimuthing solutions promise maneuverability and potential efficiency gains for targeted vessel segments such as ferries, offshore wind SOVs, and cruise ships. -

Algorithmic & AI-based Optimization

Real-time performance monitoring, adaptive control of injection and turbocharging, and data-driven hull-propeller optimization — including modern propeller design workflows using CFD and machine-learning-aided optimization. -

Integration with Emissions and Energy Systems

Waste heat recovery, EGR/SCR combinations, scrubbers, pressure-equalized sealing, and condition-based maintenance (CBM) strategies are increasingly embedded from the concept stage.

Frequently Asked Questions (FAQ)

Q1: Why not always choose a slow-speed engine and avoid the gearbox entirely?

Large merchant ships often do. But constraints like hull dimensions, engine room height, or modularity can favor medium-speed units. Flexibility for alternative fuels or machinery layout also points to medium-speed + gearbox configurations in many designs.

Q2: Which is better: FPP or CPP propellers?

Fixed-pitch propellers are simpler and cheaper, best for near-constant speeds. Controllable-pitch propellers allow thrust reversal and fine speed control at constant RPM, ideal for variable profiles and high maneuverability needs.

Q3: What happens if the thrust bearing fails?

Potential shaft displacement, misalignment, seizure, and damage to the propulsion line and hull. That’s why thrust bearings are closely monitored and designed with margin and redundancy.

Q4: Can hybrid or electric propulsion fully replace conventional main engines for large ocean-going vessels?

For long-haul deep-sea trades, full battery-electric is limited by energy density and infrastructure. Hybrid systems and alternative-fuel engines are practical transitional solutions over the next decade.

Q5: How is maintenance managed in a propulsion system with so many components?

Through scheduled intervals (including class surveys and docking), condition-based monitoring (vibration, oil analysis, temperatures), redundancy, and increasingly predictive maintenance enabled by sensor data.

Q6: What’s the difference between diesel-mechanical and diesel-electric in this context?

Diesel-mechanical couples engine torque to the propeller via shafts and possibly gearboxes. Diesel-electric uses engines to generate electricity that powers electric motors driving propulsors, improving layout flexibility and control at the cost of electrical conversion complexity.

Q7: How do regulations like sulphur caps and carbon intensity indexes affect propulsion design?

They push fuel-efficient designs, alternative fuels, hybridization, and emissions after-treatment. Compliance is now baked into propulsion choices from day one.

Conclusion & Forward Look

The main propulsion system is the lifeblood of any ocean-going vessel. From the colossal slow-speed engine to the slender tail shaft and propeller blades, every component must work in harmony. Understanding this chain is crucial not just for engineers onboard or ashore, but for shipowners, maritime students, and decision-makers facing a more challenging, greener future.

As regulation tightens and zero-emission goals draw nearer, propulsion systems will evolve. Dual-fuel engines, electric-hybrid configurations, PODs, AI-optimized control, and novel materials are stepping into the spotlight. The next decade promises exciting—yet demanding—shifts in how ships are powered.

This gave me a whole new perspective on something I thought I already understood. Great explanation and flow!

This was so insightful. I took notes while reading!

Your content always adds value to my day.

You clearly know your stuff. Great job on this article.