MARPOL, short for Marine Pollution, is one of the most important international marine environmental conventions. It was designed to minimize pollution of the seas, including dumping, oil, and exhaust pollution. Annex I specifically deals with the prevention of pollution by oil from operational measures as well as from accidental discharges. The Annex covers various aspects of ship design and equipment, operational procedures, and requirements for the control of operational pollution.

Cargo Tank Cleaning Procedures

1. Pre-Cleaning Phase

Before cleaning cargo tanks, it is essential to ensure that all safety checks are in place. This includes checking the inert gas system, ensuring that the tanks are properly ventilated, and confirming that no sources of ignition are present. Crew members involved in the cleaning must wear appropriate personal protective equipment (PPE).

2. Cleaning Methods

Several methods are employed for tank cleaning, depending on the previous cargo, the next cargo, and the required cleanliness level:

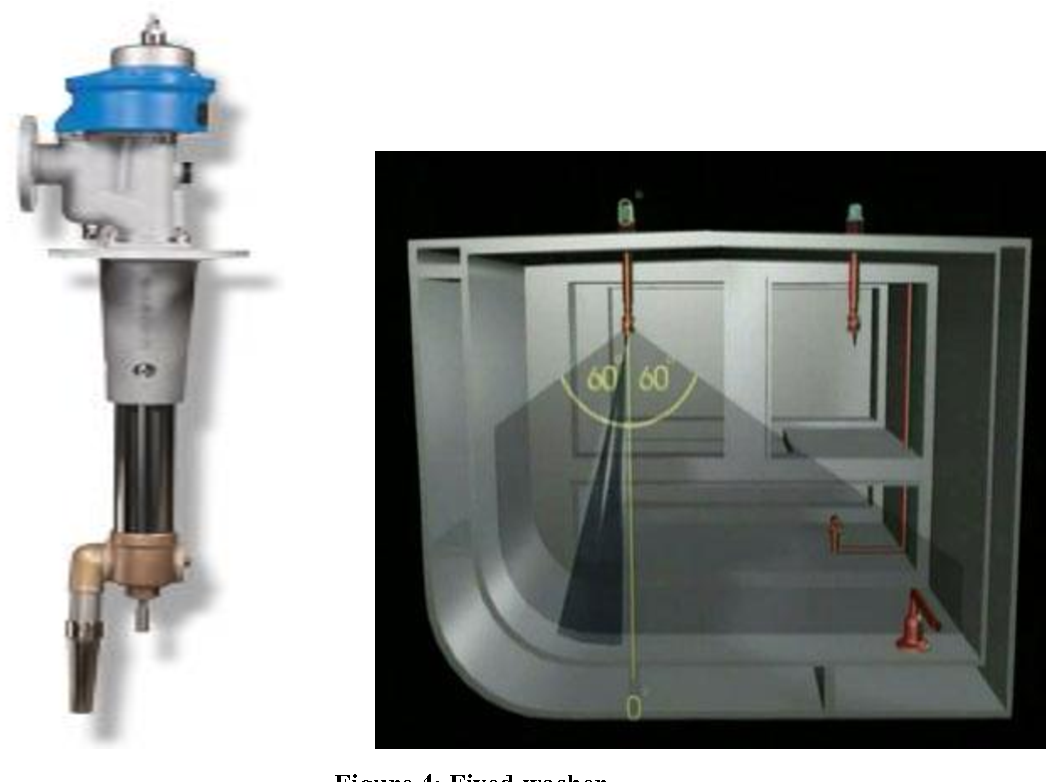

- Crude Oil Washing (COW): Used primarily on tankers carrying crude oil. This process involves using the oil itself, sprayed back onto the sides of the tanks to wash down residues. COW reduces the need for water-based cleaning and minimizes the amount of oily water generated.

- Water Washing: Involves high-pressure water jets to remove residues. The water used can be either fresh or sea water, often heated to improve cleaning efficiency.

- Chemical Cleaning: Used when residues are deemed too difficult to remove with water. Specific chemicals designed for tank cleaning are used, taking care to handle and dispose of them in accordance with MARPOL regulations.

3. Control of Cleaning Discharges At Sea

When it comes to the control of discharges during and after the cargo tank cleaning process on ships, the provisions of MARPOL Annex I are stringent and designed to minimize environmental impact. The discharge of oil-polluted water from cargo tanks is subject to several operational and equipment-related requirements that ensure the adherence to permitted levels.

The discharge of wash water from cargo tank cleaning is highly regulated under MARPOL Annex I, which includes several specific provisions designed to prevent pollution. These regulations focus on the treatment and release of oily mixtures, ensuring that the maritime environment is protected during and after cargo tank operations.

Operational Procedures for Discharge:

- En Route Condition: Legally, a ship can only discharge wash water while it is en route, ensuring it is moving under its own propulsion. This aids in the natural dilution and dispersion of discharged substances.

- Oil Content Limitation: The discharge must not contain more than 15 parts per million of oil. Continuous monitoring via an oil discharge monitoring and control system is required to ensure compliance with this regulation.

- Distance from Nearest Land: Discharges must occur at least 12 nautical miles from the nearest land, a critical measure to protect sensitive marine and coastal ecosystems.

- Oil Discharge Monitoring and Control System (ODMCS): This approved system by flag (or R.O) plays a crucial role in managing discharges. It stops the discharge process automatically if the oil content exceeds 15 ppm or if there is a system failure, thereby ensuring adherence to international standards.

4. Sludge and Residue Management

The management of sludge and residues from cargo tank cleaning is a critical aspect of operational pollution control. MARPOL Annex I mandates specific procedures for handling, storing, and disposing of these substances.

Sludge Accumulation: Sludge in cargo tanks primarily accumulates from the sediment of the cargo oil, chemical residues, and water emulsions. Regular cleaning helps in managing the levels of sludge. Dedicated tanks are used to store sludge on board ships. These tanks are often equipped with heating coils to maintain the sludge in a fluid state for easier handling and transfer.

Handling and Transfer, Documentation and Records: Sludge must be transferred carefully to avoid any spills. Pumps and pipelines used for the transfer are designed to handle viscous fluids efficiently. Each transfer or disposal operation must be meticulously documented in the Oil Record Book, providing transparency and facilitating inspections.

Disposal Ashore: Ships are required to dispose of sludge and tank washing residues at port reception facilities. These facilities are equipped to handle and treat oily waste in an environmentally friendly manner.

The use of port reception facilities and the compliance with local and international regulations are crucial for the legal disposal of sludge.

Onboard Incineration: Some ships are equipped with incinerators approved for the burning of sludge under controlled conditions. Incineration must comply with both MARPOL Annex I and Annex VI regarding air emissions.

These expanded details highlight the rigorous requirements and sophisticated equipment needed to manage and control the environmental impacts of cargo tank operations on ships. By adhering to MARPOL Annex I, ships not only comply with international regulations but also contribute to the broader goal of protecting marine and coastal ecosystems. This comprehensive approach ensures that the maritime industry remains responsible and sustainable, minimizing its ecological footprint while maintaining operational efficiency.

I like your information about the ship and …

thank you so much.