Master the art of measuring PMAX (maximum combustion pressure) in marine diesel engines. This hands-on guide explains tools, safety steps, and analysis for better performance, efficiency, and STCW compliance.

Why PMAX Measurement Matters in Marine Engine Operations

PMAX, or maximum combustion pressure, is one of the most important indicators of cylinder performance in a marine diesel engine. It reflects how well combustion is taking place inside the engine cylinder. By measuring PMAX regularly, marine engineers can identify:

- Fuel injection problems

- Combustion delays

- Injector nozzle wear

- Ignition timing errors

Regular PMAX checks help avoid costly repairs, improve fuel efficiency, and reduce harmful emissions—all while keeping vessels compliant with IMO and STCW engine performance monitoring requirements.

Understanding PMAX and Combustion Performance

PMAX is the highest pressure reached during the combustion cycle in a diesel engine cylinder. It is typically measured in bar or MPa using a mechanical or digital indicator.

Why It Matters:

- A low PMAX may indicate poor combustion, leaking injector nozzles, or delayed ignition.

- A high PMAX may suggest over-fueling, incorrect timing, or mechanical resistance.

Monitoring PMAX across all cylinders ensures uniform combustion and balanced power output.

Tools and Safety Gear for PMAX Measurement

Tools Required:

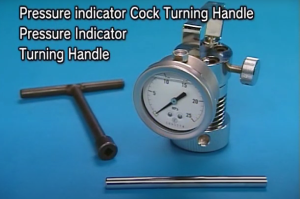

- Pressure indicator (mechanical or electronic)

- Anti-burnout compound (to protect threads)

- Wrenches and valve keys

- Cylinder indicator cock (fitted on engine)

Safety Equipment:

- Heat-resistant gloves

- Safety goggles or face shield

- Protective overalls

Step-by-Step: How to Measure PMAX Safely and Accurately

1. Prepare the Indicator

- Apply anti-burnout paste to the thread of the pressure indicator.

- Operate the exhaust valve of the indicator a few times (“gunning it”) to ensure it is functional.

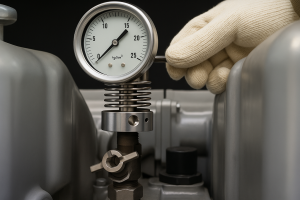

2. Install the Indicator

- Fix the indicator securely to the cylinder indicator cock.

- Ensure it is seated tightly to avoid leaks.

3. Open Cylinder Valve

- Slowly open the valve on the indicator cock.

- Watch the pressure gauge rise as the engine cycles.

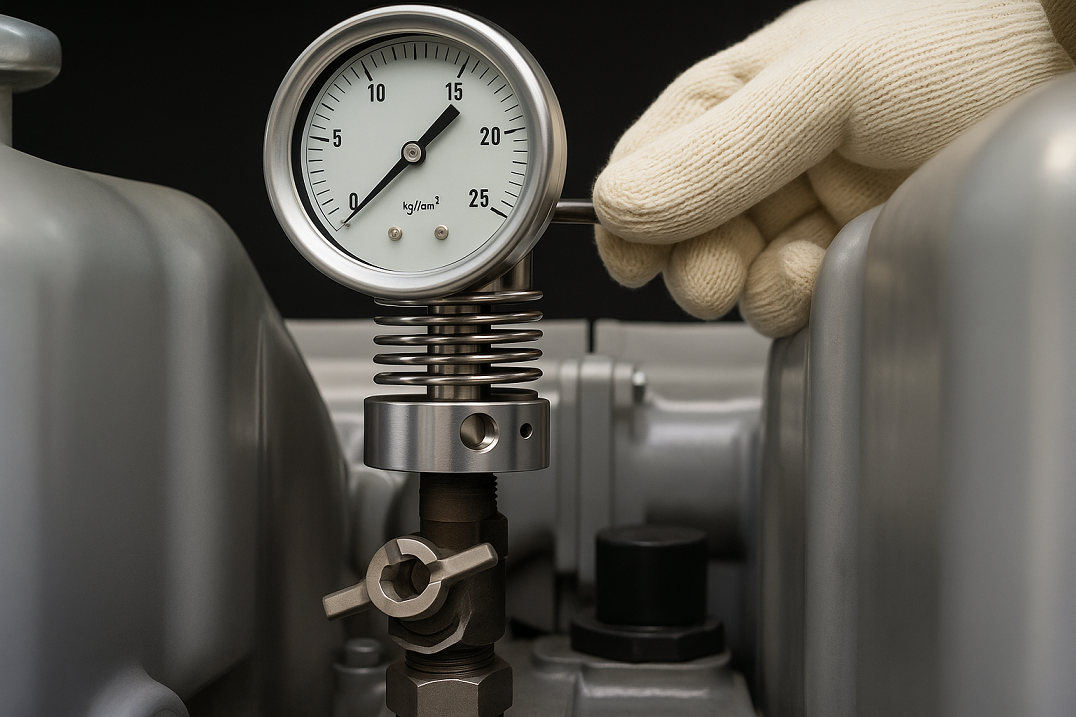

4. Record Peak Pressure

- When the needle reaches the maximum point (PMAX), take the reading.

- Wait until the pressure stabilizes and no longer increases.

5. Depressurize Before Removal

- Open the exhaust valve on the indicator to release internal pressure.

- Ensure the needle returns to zero.

- Only then remove the pressure indicator to avoid burns or injury.

Analysis: What the Numbers Tell You

Ideal PMAX Range:

- Depends on engine type and maker specs (e.g., 80–120 bar for medium-speed engines).

Compare PMAX readings across cylinders:

- Uniform readings indicate healthy engine operation.

- Wide variation (more than 3–5 bar difference) may indicate:

- Worn injectors

- Poor compression

- Scavenge air problems

Plotting PMAX data over time can also reveal performance trends and assist in planning preventive maintenance.

Real-World Example: Preventing Major Engine Trouble

Onboard a bulk carrier, engineers detected a PMAX reading of 70 bar on Cylinder #3, while others measured 110 bar. Upon inspection, the injector nozzle was partially clogged, affecting fuel atomization.

Early detection through PMAX monitoring prevented a potential piston ring failure and avoided an unscheduled dry-docking. Estimated savings: over USD 50,000.

Best Practices for Reliable PMAX Measurement

- Always measure at stable engine load (not during load changes).

- Calibrate your mechanical indicators periodically.

- Maintain a PMAX logbook for trend analysis.

- Clean indicator ports before and after each use.

FAQ: Common Questions About PMAX Checks

1. How often should PMAX be measured?

Usually every 500–1000 engine hours, or during routine overhauls.

2. Can I use digital indicators?

Yes. Digital indicators offer more precise data and can graph the pressure curve, but mechanical types are still widely used.

3. What if PMAX is too low?

Check injector performance, fuel quality, compression, and valve timing.

4. Is PMAX measurement required by regulation?

Yes, under STCW Code and many ISM checklists, performance monitoring is required.

5. Can I measure PMAX while the engine is running?

Yes, the engine must be running under load during the measurement.

Conclusion: PMAX Monitoring = Smarter Engine Management

Measuring PMAX is one of the most effective ways to assess marine engine health. It provides early warnings for faults, helps fine-tune fuel injection systems, and ensures that all cylinders are working in harmony.

By mastering this simple yet powerful diagnostic tool, marine engineers and cadets can improve engine efficiency, prevent failures, and meet international performance standards.

References

- MAN Energy Solutions. (2023). Engine Performance Monitoring Guide. https://www.man-es.com

- Wärtsilä. (2024). Combustion Pressure Measurement Manual. https://www.wartsila.com

- IMO. (2022). STCW Code, Part A – Performance Monitoring Requirements. https://www.imo.org

- IACS. (2023). Engine Data Logging and Evaluation Standards. https://www.iacs.org.uk

- DNV. (2023). Engine Diagnostics and Performance Audits. https://www.dnv.com

wow