Comprehensive step-by-step overhaul guide for marine diesel engine fuel injection pumps. Disassembly, inspection, reassembly, timing, and maintenance explained.

Introduction

The fuel injection pump is the heart of a marine diesel engine’s combustion system. It ensures that the right amount of fuel is injected into each cylinder, at the right pressure, and at the precise timing needed for efficient power generation. Even minor wear or misalignment in the pump can result in poor combustion, reduced efficiency, high emissions, or catastrophic engine damage.

Routine overhaul and inspection of the fuel injection pump is therefore essential for safe, efficient ship operations. The training video Fuel Injection Pump Overhaul Procedure demonstrates the practical onboard process. This article expands that procedure into a comprehensive guide enriched with theory, class requirements, troubleshooting, and real-world best practices.

The Role of the Fuel Injection Pump

Function in Marine Diesel Engines

The fuel injection pump is a critical component in a marine diesel engine, responsible for generating the extremely high pressure—typically between 350 and 1,200 bar in low- and medium-speed engines—required to atomize fuel for effective combustion. Its primary function is to deliver a precisely metered quantity of fuel to each cylinder at an exact moment in the combustion stroke. This precise control over fuel quantity is achieved through a mechanical rack and plunger system, which works in close coordination with the engine’s governor to automatically adjust the fuel delivery in response to changes in engine load.

- Pressurizes fuel (350–1,200 bar in low/medium speed engines).

- Delivers fuel precisely timed to the combustion stroke.

- Controls quantity through the rack and plunger system.

- Works in coordination with the governor to adjust engine load.

Types of Fuel Injection Pumps

Several types of fuel injection pumps are employed across the maritime fleet. The jerk-type pump is a traditional and common design, particularly in large-bore, slow-speed two-stroke engines. In contrast, modern common rail systems, used by manufacturers like MAN and Wärtsilä, represent the latest technological advancement. For smaller auxiliary engines, Bosch-type inline pumps are frequently utilized. This article will focus primarily on the operation and maintenance of the jerk-type fuel pumps found on many low- and medium-speed marine engines.

- Jerk-type pump (common in large slow-speed engines).

- Common rail systems (modern MAN/Wärtsilä).

- Bosch-type inline pumps (auxiliary engines).

This article focuses on jerk-type fuel pumps found on many low- and medium-speed marine engines.

Overhaul Intervals & PMS Integration

Maintenance overhauls are conducted on a routine basis, typically during a scheduled drydock period, or proactively if performance monitoring indicates emerging issues. Specific components, such as the tumpet and roller assembly, have a defined service life and are generally overhauled at intervals of 8,000 to 10,000 operating hours, as stipulated by the engine maker’s manuals and established operational practice. To ensure traceability and proper maintenance planning, all overhaul activities must be meticulously integrated into the Planned Maintenance System (PMS). This requires logging key details including the date of the overhaul, a comprehensive list of any parts that were replaced, and the results of any subsequent calibrations or performance tests.

Tools and Preparations

Tools Required

-

Socket wrench set.

-

Special tools for plunger and guide insertion.

-

Torque wrench for staged tightening.

-

Dial gauge (for fuel timing).

-

Cleaning solvents and brushes.

Safety Precautions

-

Isolate fuel system, depressurize lines.

-

Wear gloves and eye protection.

-

Prevent dust/oil contamination — fuel pump components are high-precision parts.

-

Never mix components from different pumps (keep parts matched).

Step-by-Step Overhaul Procedure

The video provides the backbone — here expanded into detailed technical notes.

1 Removal of the Fuel Pump

-

Disconnect high-pressure fuel pipes.

-

Loosen delivery valve and fuel rack nuts.

-

Remove pump from bracket using socket wrench.

-

Cover open pipes and ports to prevent dirt ingress.

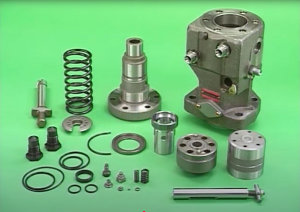

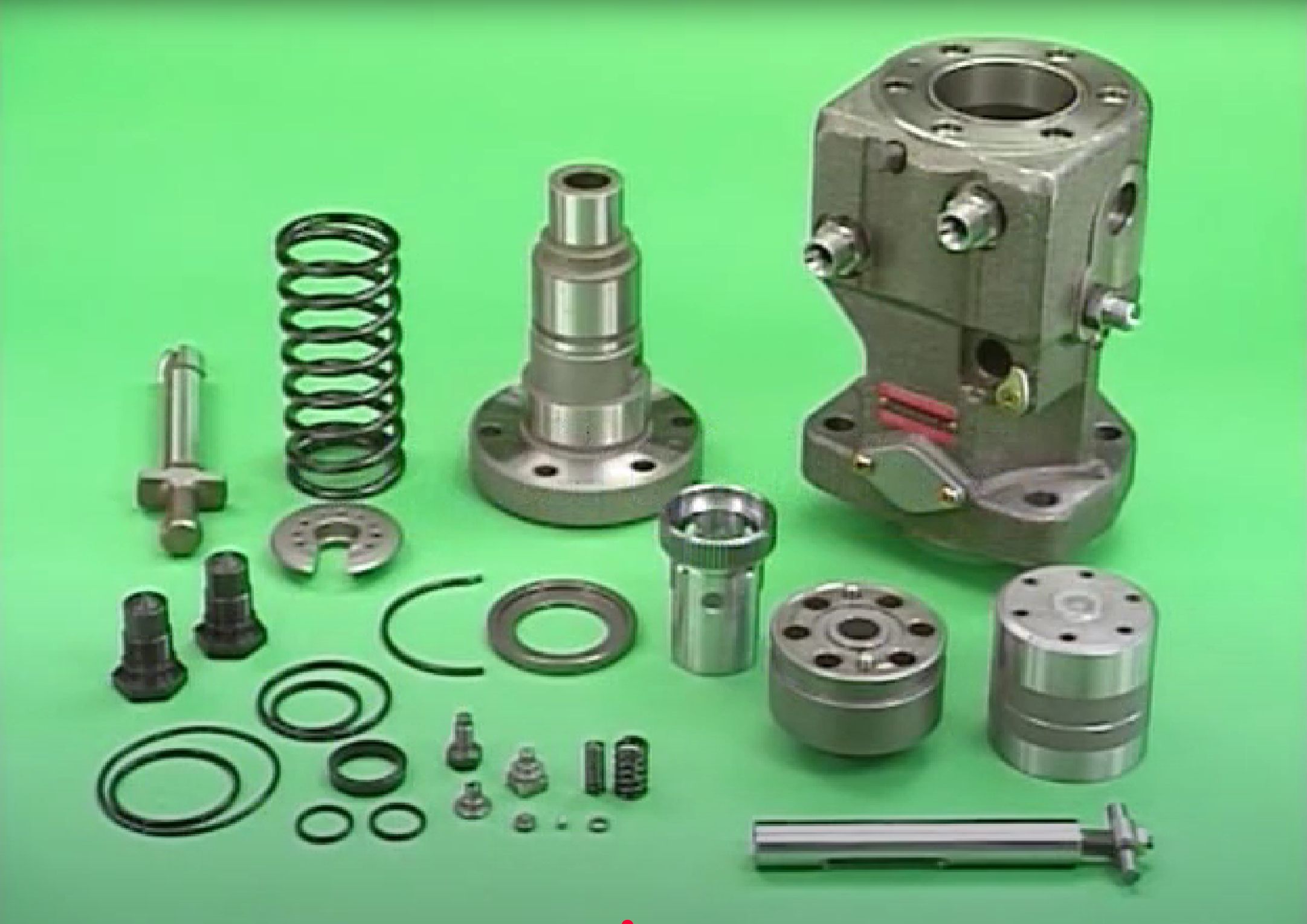

2 Disassembly of Pump

-

Remove plunger guide, spring, pinion, and retainer.

-

Withdraw fuel rack, deflectors, and barrel assembly.

-

Carefully remove all O-rings (replace during reassembly).

-

Handle delivery valve and plunger with clean hands only — precision tolerances are within microns.

3 Inspection of Components

-

Plunger & Barrel: Check for scoring, scratches, or wear using magnifying glass. Even small damage causes pressure loss.

-

Delivery Valve: Inspect seating surfaces for leakage.

-

Rack & Pinion: Ensure smooth engagement without play.

-

Springs & Guides: Check for deformation or cracks.

-

O-rings: Always renew.

🧪 Tip: Use penetrant testing for cracks in high-stress parts like the plunger top.

4 Cleaning

-

Wash all metallic parts in clean diesel or kerosene.

-

Avoid using rags that shed lint.

-

Dry with compressed air.

5 Reassembly of Pump

-

Insert plunger and barrel with correct orientation.

-

Align rack, pinion, and plunger set marks precisely (critical for injection timing).

-

Fit plunger guide with exclusive tool.

-

Reinstall delivery valve assembly and spring.

-

Tighten bolts in three torque stages as per maker’s manual (e.g., 30%, 60%, 100%).

-

Check that rack moves smoothly through full range.

–

Reinstallation & Testing

1 Installation Back to Engine

-

Position pump on bracket.

-

Connect rack and tappet linkage.

-

Refit high-pressure pipes.

-

Renew gaskets and O-rings.

2 Fuel Injection Timing Check

-

Align line marks on pump and engine timing gear.

-

Use dial gauge or spill timing method.

-

Confirm timing matches engine maker’s specification.

3 Air Bleeding

-

Open vent screws, operate hand pump to remove air.

-

Run slow turning gear to confirm injection.

–

Final Checks After Overhaul

-

Ensure rack movement is smooth and synchronized.

-

Confirm no leaks from connections.

-

Monitor exhaust temperature balance during trial run.

-

Record all work in engine logbook/PMS.

Troubleshooting & Common Problems

| Symptom | Likely Cause | Corrective Action |

|---|---|---|

| Black smoke | Late injection timing, worn plunger/barrel | Re-time pump, renew plunger/barrel |

| High exhaust temp | Incorrect rack setting, faulty delivery valve | Adjust rack, renew valve |

| Misfiring cylinder | Air in system, pump sticking | Bleed air, overhaul pump |

| Fuel leakage | Worn O-rings, cracked barrel | Replace seals, inspect barrel |

| Rack not moving | Pinion misaligned or stuck | Realign pinion, clean & lubricate |

Regulatory Requirements

The overhaul and maintenance of fuel injection systems are governed by a stringent framework of international conventions and class rules. The SOLAS Convention, in Chapter II-1, mandates that ship engines and their critical systems, including fuel systems, must be maintained to ensure continuous safety and reliability. Complementing this, the STCW Convention requires that marine engineers, as a core competency, possess a thorough understanding of fuel injection system maintenance and overhaul procedures. Furthermore, classification societies such as DNV, LR, and ABS conduct inspections of these systems as part of their special survey requirements to verify compliance. Beyond safety and performance, proper fuel injection maintenance is also an environmental imperative under MARPOL Annex VI, as precise injection is essential for achieving complete combustion, which in turn minimizes the release of harmful emissions.

Case Studies – Lessons from the Sea

Case 1 – Injector Knock from Poor Overhaul

A chief engineer reused old O-rings during a hurried overhaul. Air leakage caused irregular injection timing → knocking noise, reduced efficiency. Lesson: always renew seals.

Case 2 – Fuel Rack Sticking at Sea

Improper cleaning of rack/pinion led to rack sticking. Engine could not reduce speed, nearly causing collision. Lesson: verify free rack movement before engine run.

Case 3 – Exhaust Temp Imbalance

A container ship reported high exhaust temperature on one unit. Overhaul revealed plunger wear reducing pressure. Replacement restored balance.

Best Practices for Engineers

-

Work in clean, dust-free area.

-

Always follow maker’s manual torque values.

-

Replace consumables (O-rings, gaskets) every overhaul.

-

Keep detailed trend records of exhaust temp, fuel pump performance.

-

Train cadets on simulators before live engine overhauls.

Future Trends – Electronic Fuel Injection

- Common rail systems replacing mechanical jerk pumps.

- ECU (Electronic Control Units) adjust timing, pressure, and fuel quantity digitally.

- Benefits: reduced emissions, improved combustion, fuel savings.

- Engineers must be trained in diagnostics and electronic calibration.

Conclusion

The fuel injection pump is a high-precision component, central to the safe and efficient operation of marine diesel engines. The video demonstrated the practical steps for overhaul; this article expanded into a detailed technical guide covering:

- Disassembly, inspection, and cleaning.

- Alignment of rack, pinion, and plunger marks.

- Correct torque/angle tightening and smooth rack movement.

- Reinstallation with timing checks and air bleeding.

- Troubleshooting, regulatory compliance, and modern trends.

By mastering this procedure, marine engineers not only ensure efficient combustion and reduced emissions but also fulfill the requirements of SOLAS, STCW, and classification society standards.

Exactly, 🙏