Discover the most vital instruments and tools used in ship engine rooms for safety, performance, and compliance. A must-read for maritime cadets and professionals.

The engine room is the powerhouse of a ship, containing critical systems responsible for propulsion, electrical generation, and auxiliary functions. Monitoring these systems requires a suite of essential instruments, each playing a key role in maintaining safety, operational efficiency, and compliance with maritime standards. This guide explores the most vital instruments found in a ship’s engine room and the specialized tools used by marine engineers for maintenance.

Key Engine Room Instruments and Their Functions

1. Pressure Gauges Used to monitor pressure in fuel systems, lubricating oil circuits, cooling water lines, and steam systems. These readings help detect leaks, clogs, or pump malfunctions, ensuring safe operation.

2. Temperature Indicators and Pyrometers These include bimetallic thermometers, infrared thermometers, and pyrometers. They monitor temperatures in:

- Jacket cooling water

- Lubricating oil

- Turbocharger exhaust gases

- Heat exchangers

Timely detection of overheating prevents severe engine damage.

3. Tachometers Display the RPM (rotations per minute) of the main and auxiliary engines. Maintaining optimal RPM ensures efficient propulsion and fuel usage.

4. Flow Meters Track the volume and velocity of fuel, oil, and water flow. Engineers rely on these meters to optimize fuel consumption and lubrication.

5. Oil Mist Detectors Detects fine oil particles in crankcases. A high concentration may indicate impending bearing failure, frictional heat, or the risk of explosion.

6. Water Level Indicators Installed in boilers and tanks, they prevent low-water situations that can result in overheating or boiler explosion.

7. Alarm and Monitoring Systems Modern systems use integrated panels and software to alert engineers in real-time to deviations from safe operating conditions (e.g., low lube oil pressure, high exhaust gas temp).

8. Engine Control Room (ECR) Displays A central digital interface used by engineers to monitor parameters from multiple systems. Enables rapid decision-making and control.

Maintenance and Calibration Tools Used Alongside Instruments

Though not instruments themselves, these tools are essential to maintain the integrity of engine instrumentation and systems:

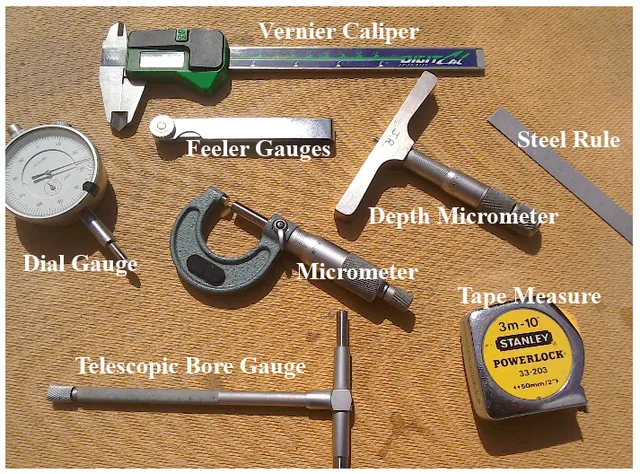

Measuring and Calibration Tools:

- Vernier Calipers and Micrometers: For measuring piston ring gaps, liner wear, and shaft diameters.

- Feeler Gauges: To measure valve clearances.

- Dial Gauges: Used for crankshaft deflection and alignment.

- Cylinder Bore Gauges: Assess wear inside cylinder liners.

Monitoring Devices (Portable):

- Infrared Thermometers: Check surface temperatures without contact.

- Handheld Vibration Analyzers: Detect shaft misalignment or worn bearings.

Case Study: On a gas carrier, a marine engineer used micrometers to inspect liner thickness during planned maintenance, identifying wear before it impacted performance.

Power and Specialized Tools in Engine Room Maintenance

Power Tools:

- Impact Wrenches: High torque removal of engine mounts or propeller nuts.

- Angle Grinders: Rust removal and surface prep.

- Electric Drills: Used during modifications or mounting components.

Specialized Tools:

- Valve Seat Cutters

- Bearing Pullers

- Hydraulic Jacks & Chain Hoists: For lifting heavy engine components

Cleaning and Safety Tools:

- Degreasers, Brushes, Industrial Vacuums

- Personal Protective Equipment (PPE)

- Gas Detectors

Example: During a fuel pump overhaul on a bulk carrier, an engineering team used an impact wrench and angle grinder to reduce downtime by 30%.

Why These Instruments and Tools Matter

- Safety: Real-time monitoring ensures quick response to hazardous conditions.

- Efficiency: Ensures optimal performance and extends machinery life.

- Compliance: Accurate logs of parameters are required under SOLAS, MARPOL, and class rules.

For aspiring marine engineers, cadets, and professionals, mastering these instruments and associated tools is crucial for both routine operations and emergencies.

FAQs

Q: Are portable measurement tools considered engine room instruments? A: Not technically. Instruments refer to fixed monitoring equipment. However, tools like micrometers are essential for engine inspections and maintenance.

Q: Why are oil mist detectors critical? A: They prevent catastrophic crankcase explosions by warning of unsafe mist concentrations early.

Q: What’s the role of the ECR in engine instrumentation? A: The Engine Control Room provides engineers with central access to monitor and control all major engine room systems.

References & Further Reading:

- Essential Tools in a Ship’s Engine Room – MaritimEducation.com

- Tools and Instruments Commonly Used in the Engine Room – MaritimEducation.com

- Kongsberg Maritime: Engine Room Automation Systems

- Wikipedia: Engine Room

- Martide: Engine Room Equipment

very good, thanks!