Anchoring is a critical operation in ship navigation, essential for ensuring vessel stability, safety, and operational efficiency. Dropping and lifting anchors require precise execution, proper communication, and adherence to maritime regulations. A well-executed anchoring procedure safeguards the ship, crew, cargo, and marine environment. This article explores the procedures involved in dropping and lifting anchors on ships, emphasizing best practices, operational guidelines, and real-world case studies to highlight the importance of this essential maritime operation.

Anchoring secures a ship in place when docking at a port, awaiting berth clearance, or holding position in designated anchorages. Ships also anchor in emergencies, such as engine failures or rough weather, to avoid drifting into hazardous areas.

Key Scenarios for Anchoring:

- Waiting for a berth at congested ports like Singapore or Rotterdam.

- Emergency anchoring during navigation equipment failure.

- Securing a vessel during repairs or cargo handling in port.

Credit: https://www.myseatime.com/blog/detail/the-ultimate-actionable-guide-of-anchoring-a-ship

–

Preparation Before Dropping the Anchor

1. Pre-Anchoring Checklist

Before initiating the anchoring process, the ship’s crew must prepare thoroughly by:

- Checking the Anchor and Windlass: Inspect the windlass, chains, and brakes to ensure they are in working condition.

- Navigational Equipment Check: Verify the accuracy of the ship’s GPS, radar, and depth sounder.

- Weather Forecast Review: Consider wind, tide, and current conditions to select a safe anchoring location.

- Communication Setup: Establish radio communication between the bridge, anchor team, and engine room.

2. Selecting the Anchoring Position

The following factors determine the best anchoring position:

- Seabed Composition: A firm seabed (sand or mud) offers the best holding ground.

- Depth of Water: The anchoring depth should allow the appropriate scope of chain length.

- Safety Distance: Ensure safe clearance from nearby vessels, ports, and navigational hazards.

Example: In the English Channel, ships choose sandy seabed areas to anchor securely and avoid strong tidal currents.

3. Determining Anchor Chain Length

The scope of the anchor chain is critical for ensuring the ship remains stationary. The recommended ratio between the anchor chain length and water depth is typically 5:1 to 7:1, depending on environmental conditions.

Formula for Chain Length:

Anchor Chain Length=Water Depth+Height of Ship’s Hawsepipe Above Water×Scope Ratio (5 to 7)\text{Anchor Chain Length} = \text{Water Depth} + \text{Height of Ship’s Hawsepipe Above Water} \times \text{Scope Ratio (5 to 7)}

Case Study: During a cargo operation delay in Singapore Anchorage, a bulk carrier used a 7:1 scope ratio to remain securely anchored amid strong tidal currents.

—

Procedure for Dropping the Anchor

1. Bridge-to-Deck Communication

The officer on the bridge must maintain continuous communication with the anchoring team, ensuring all commands are clear and acknowledged.

2. Approach the Anchoring Position

- Reduce the ship’s speed to 1-2 knots while approaching the anchoring point.

- Use bow thrusters and engines for precise maneuvering.

3. Dropping the Anchor

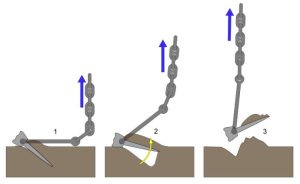

- Anchor Ready: Confirm that the anchor is free and ready to drop.

- Release the Brake: Slowly release the brake to let the anchor fall under gravity.

- Pay Out the Chain: Let the chain run freely as the ship moves astern.

- Control Chain Speed: Use the windlass brake to control the chain’s speed, avoiding sudden jerks that could damage the equipment.

4. Securing the Vessel

- Apply the Brake: Secure the windlass brake when the desired chain length is reached.

- Monitor the Ship’s Position: Use GPS, radar, and visual bearings to monitor the ship’s position and confirm that the anchor is holding securely.

- Anchor Watch: Establish an anchor watch to monitor ship movement, especially during changing tides or adverse weather conditions.

—Procedure for Lifting the Anchor

Credit: https://www.myseatime.com/blog/detail/the-ultimate-actionable-guide-of-anchoring-a-ship

Lifting the anchor (weighing anchor) is equally crucial and involves several coordinated steps to ensure safe departure.

1. Preparation Before Weighing Anchor

- Engine Readiness: Ensure that the engine is ready to maneuver.

- Anchor Team Standby: Assemble the anchor team at the forecastle deck with proper personal protective equipment (PPE).

- Communication Check: Establish communication between the bridge and anchor team.

2. Lifting the Anchor

- Bridge Command: The officer on the bridge commands the anchor team to lift the anchor.

- Use the Windlass: Engage the windlass to heave up the anchor while controlling chain tension.

- Slow Ahead Speed: Apply slow ahead engine movement to reduce the strain on the windlass.

3. Cleaning the Anchor and Chain

- Washdown Operation: Use high-pressure water jets to clean the anchor and chain of mud, debris, or marine growth.

4. Securing the Anchor

- Anchor Secured: Confirm that the anchor is fully housed in the hawsepipe and secured with the chain stopper.

- Inspection: Inspect the chain and windlass for damage before proceeding to the next voyage.

—

Safety Considerations During Anchoring Operations

Safety is paramount during anchoring operations due to the potential for heavy equipment failures, crew injuries, or ship collisions.

Best Safety Practices:

- Crew PPE: Crew must wear safety helmets, gloves, and steel-toed boots.

- Clear Deck: Ensure the deck area is clear of unnecessary personnel and equipment.

- Controlled Speed: Avoid sudden speed changes when lowering or lifting the anchor.

- Watchkeeping: Maintain an anchor watch to detect any dragging or environmental changes.

Case Study: Anchor Failure Incident

In 2017, a container ship experienced an anchor chain failure while anchoring off the Port of Long Beach. The investigation revealed that improper brake maintenance led to the incident, causing severe damage to the ship’s bow and delaying its cargo operations by three days.

—

Challenges and Mitigation in Anchoring Operations

Despite well-defined procedures, anchoring operations face challenges such as:

- Strong Winds and Currents: Use extra chain length and bow thrusters to counteract strong winds.

- Congested Anchorage Areas: Maintain proper lookout and adhere to COLREGS to avoid collisions.

- Equipment Failure: Conduct regular maintenance of the windlass, brakes, and anchor chains.

Dropping and lifting anchors is a fundamental aspect of maritime operations that requires technical skill, teamwork, and adherence to established procedures. By following best practices, using proper communication, and conducting equipment maintenance, ships can anchor safely and efficiently, ensuring smooth maritime operations and environmental safety.

Mariners must continually train, practice anchoring drills, and remain updated on industry standards to minimize risks and maintain the highest levels of operational readiness at sea.

Excuse, it is removed

Your passion for this topic shines through in your writing It’s clear that you put a lot of effort and thought into your posts Thank you for sharing your knowledge with us