Why Crude Oil Washing Matters in Modern Maritime Operations

Crude Oil Washing (COW) is more than a cleaning procedure—it is a critical safety, efficiency, and compliance measure in the operation of oil tankers. Introduced after major oil spills in the 1970s, COW became a regulatory standard to minimize sludge buildup, reduce oil residues, and lower the risk of pollution. Today, COW is governed by strict international regulations and terminal guidelines to ensure both environmental safety and operational efficiency.

For tanker cadets, junior officers, and shipboard trainers, understanding COW is not just about compliance but about performing a complex task with high safety standards. With hydrocarbons involved, the stakes are high. Mismanagement can lead to static discharges, fires, or pollution incidents. Therefore, solid procedural knowledge, safety awareness, and communication with terminal authorities are vital.

What Is Crude Oil Washing (COW)?

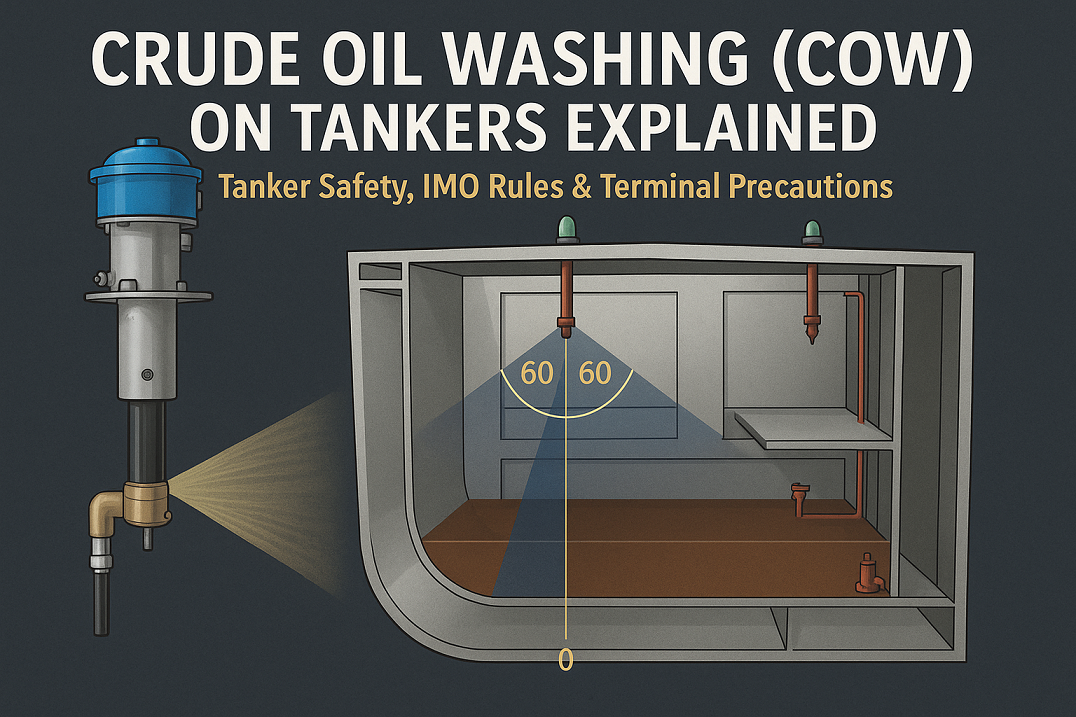

COW involves using part of the cargo (crude oil) to wash down the cargo tank walls during or after discharge. The process is carefully planned and executed under strict parameters:

- Purpose: Remove clingage (residual oil), reduce sludge formation, and improve outturn (discharged quantity).

- Process: The oil is pumped through fixed or portable COW machines and sprayed at high pressure on the internal tank surfaces.

- Timing: Often done simultaneously with cargo discharge to save time and energy.

This method not only boosts operational efficiency but also ensures the ship meets MARPOL Annex I discharge criteria and terminal outturn expectations.

–

Key Regulations Governing COW

1. SOLAS Reg. II-2/61

Mandates safety systems, including those to prevent fire and explosion risks during COW. Requires inert gas systems (IGS) to be fully operational during washing.

2. MARPOL Annex I Regulation 35

Outlines mandatory use of COW for certain sizes of crude oil tankers, especially those above 20,000 DWT. Also requires proper documentation, COW manuals, and officer training.

3. ISGOTT (International Safety Guide for Oil Tankers and Terminals)

Provides comprehensive best practices including pre-wash safety checks, operational sequences, and communication protocols.

4. OCIMF Guidelines

From the Oil Companies International Marine Forum, these guidelines reinforce COW as a tool for safe, efficient, and environmentally sound tanker operation.

–

Preparations Before Starting COW

Pre-Arrival Planning

Before arriving at the discharge terminal, the ship’s officers conduct a thorough pre-arrival shipboard meeting. This meeting reviews:

- COW plans

- Port discharge schedules

- Gas purging requirements

- Garbage management

- Mooring arrangements

This coordination, usually led by the Chief Officer, ensures that every department is aligned for a safe and efficient discharge.

Equipment and Safety Checks

Prior to starting the COW operation:

- Inspect manifold reducers, compound pressure gauges, and deck lighting.

- Test communication systems, remote hydraulic units, and emergency hand pumps.

- Perform a detailed inspection of the pump room, ensuring it is clean and free of combustible materials.

- Verify functionality of gas detection meters (HC, H₂S, O₂) and ensure calibration is up-to-date.

- Ensure inert gas systems are functioning correctly.

These checks are not mere formalities—they are safety nets that protect crew, cargo, and vessel.

–

Required Conditions and Safety Precautions

Minimum Cargo Level: 1 Meter Clearance

COW should not begin until at least 1 meter of oil remains above the suction line in the tank. This ensures sufficient oil volume for washing and prevents air ingress that could compromise inert conditions.

Restrictions with High-RVP Cargoes

When dealing with cargoes with Reid Vapor Pressure (RVP) above 7 psi, extra precautions are essential. High-RVP cargoes pose a higher risk of vapor formation and static discharge. Guidelines advise:

- Avoiding washing at high tank levels

- Ensuring low washing pressure

- Using anti-static measures and grounding equipment

Never Use Oil Over Settled Water

COW must never be conducted with oil settled over water in the tank. Water increases the risk of static discharge and may hinder effective cleaning. Tanks should be water-free before starting the wash.

Continuous Monitoring and Communication

Bridge, cargo control room, and pump room must maintain constant communication. Any sign of pressure spikes, equipment malfunction, or gas detection alarms requires immediate cessation of the operation.

Role of the COW Operations Manual

Each tanker is required to carry a COW Operations Manual, approved by the vessel’s flag state or classification society. This manual includes:

- Tank washing sequences

- Diagrams of fixed COW machines

- Operational checklists

- Emergency stop procedures

Crew must be thoroughly trained in its use. Any deviation from the manual must be documented and justified with terminal concurrence.

Coordination with Terminals

COW is never conducted in isolation. Terminals have their own procedures, often more stringent than IMO minimums. Chief Officers must:

- Notify terminal representatives of intent to carry out COW

- Provide washing plans and safety checklists

- Secure written permission before commencement

Terminal staff may request pauses, inspections, or adjustments depending on ongoing port operations or shore-based concerns.

Real-World Application: A Case at Ras Tanura

In a 2022 incident at Ras Tanura Terminal (Saudi Arabia), a VLCC attempted to begin COW operations without confirming inert gas pressure stability. Terminal authorities intervened when oxygen levels rose above 8% by volume, exceeding ISGOTT’s 8% threshold. The operation was halted, preventing a potential fire hazard. This underscores the importance of cross-checking tank atmosphere before and during washing.

–

Common Questions About Crude Oil Washing

1. Is COW mandatory on all crude oil tankers?

Not all. MARPOL Annex I requires it for crude carriers over 20,000 DWT unless alternate pollution prevention equipment is installed.

2. Can COW be done at anchor?

Yes, but only with terminal approval and environmental safety assurances. Local regulations (e.g., Port State Control) also play a role.

3. How long does a typical COW operation take?

Depending on the number of tanks and washing sequence, COW can last from 6 to 24 hours.

4. What training is required for COW?

Officers must be familiar with the COW manual and have completed STCW training modules relevant to crude oil operations. Shipboard drills are also recommended.

5. What happens if gas detection systems fail during COW?

Operations must be stopped immediately. Backup equipment should be activated, and the terminal informed. The operation may only resume once systems are functional and safety verified.

6. Why use crude oil instead of water for washing?

Water washing can create oil-water mixtures that are harder to manage and dispose of. Crude oil washing avoids this and utilizes available cargo to clean, improving efficiency and reducing waste.

7. Are there innovations in COW systems?

Yes. Recent technologies include programmable tank washing sequences, integration with real-time tank atmosphere monitoring, and automated shut-off valves tied to gas alarms.