Marine boilers are critical components on ships, providing essential steam for propulsion, power generation, and various auxiliary systems. They ensure the efficient operation of engines, heating, and cargo handling equipment. Properly functioning boilers enhance fuel efficiency, reduce emissions, and maintain safety standards. Their reliability is vital for smooth maritime operations, making regular maintenance and optimal performance indispensable for ship functionality and crew safety.

Marine boilers play a pivotal role in ship operations, providing the necessary steam for propulsion, heating, and other onboard processes.

However, one of the potential hazards associated with marine boilers is back-fire or blow-back.

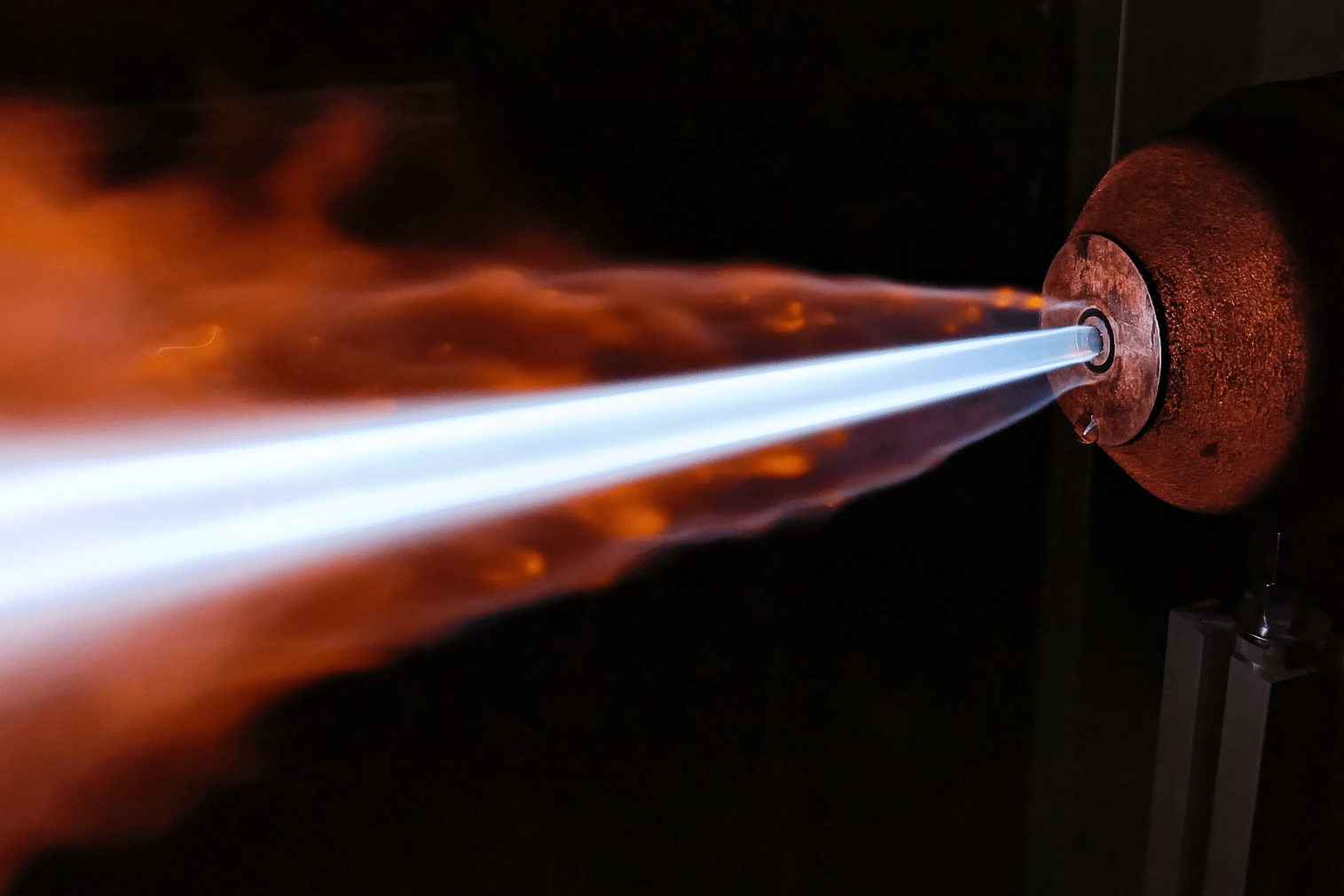

In Marine boilers, back-fire, also known as blow-back, is typically caused by the accumulation of fuel vapors or explosive/flammable gases, leading to improper combustion conditions or malfunctions within the burner system. Common contributing factors include incorrect air-to-fuel ratios, insufficient fresh air draft pressure, or blockages in the flue gas pathway. These issues can create an abnormal pressure surge, forcing flames and hot gases to flow backward into areas where they are not designed to go, such as the burner or fuel supply lines.

Causes of Back-Fire in Marine Boilers

Understanding the causes of back-fire is critical for preventing its occurrence. Below are some common reasons for back-fire in marine boilers:

1. Incomplete Combustion

- Reason: Insufficient air supply or improper fuel atomization can result in incomplete combustion.

- Impact: Unburned fuel accumulates, creating a highly flammable environment that may ignite unexpectedly.

2. Blocked or Restricted Flue Gas Path

- Reason: Soot or debris buildup in the exhaust path can restrict the smooth flow of gases.

- Impact: Pressure imbalance forces combustion gases to reverse.

3. Delayed Ignition

- Reason: Faulty ignition systems or a mismatch in air-fuel timing can delay ignition.

- Impact: Accumulated fuel can ignite explosively, causing a back-fire.

4. Burner Malfunctions

- Reason: Faulty burners, damaged nozzles, or incorrect alignment disrupt the combustion process.

- Impact: Improper fuel spraying and flame instability increase the risk of back-fire.

5. Excessive Boiler Load Fluctuations

- Reason: Sudden load changes can destabilize combustion conditions.

- Impact: Unstable pressure can lead to a reversal of gases.

Effects of Back-Fire in Marine Boilers

Back-fire incidents can have serious consequences, including:

- Damage to Equipment: Burners, fuel lines, and surrounding components may suffer damage from high-pressure flames and gases.

- Injury to Personnel: Back-fire can pose significant risks to crew members near the boiler.

- Operational Disruptions: Unplanned shutdowns for inspection and repair can delay ship schedules.

- Fire Hazards: Escaping flames may ignite surrounding materials, leading to onboard fires.

Preventing Back-Fire in Marine Boilers

Preventing back-fire in marine boilers is critical to ensuring the safety, efficiency, and longevity of a vessel’s operations. Back-fire, a dangerous condition where combustion occurs in the wrong part of the system, can lead to equipment damage, safety hazards, and operational downtime. Implementing preventive maintenance and adhering to proper operational practices are essential to mitigate this risk. Below are detailed explanations of the key measures to prevent back-fire:

1. Regular Maintenance and Inspection

Regular maintenance and inspection are fundamental to preventing back-fire in marine boilers. Over time, burners and fuel nozzles can become clogged with soot, carbon deposits, or unburned fuel residues. Cleaning these components ensures that fuel is atomized properly and combustion occurs efficiently. Additionally, inspecting combustion chambers helps identify cracks, corrosion, or other damage that could disrupt the combustion process and lead to back-fire. It is also crucial to ensure that flue gas paths are free of soot, debris, and blockages. Blockages in these pathways can cause pressure buildup, forcing flames or hot gases back into the combustion chamber or burner area. Regular cleaning of these pathways ensures smooth exhaust flow and reduces the risk of back-fire.

2. Optimal Air-Fuel Ratio

Maintaining the correct air-fuel ratio is essential for efficient combustion and preventing back-fire. An improper balance of air and fuel can lead to incomplete combustion, resulting in the accumulation of unburned fuel in the combustion chamber. This unburned fuel can ignite unexpectedly, causing a back-fire. Ensuring the correct ratio promotes complete combustion and minimizes risks. Modern marine boilers are often equipped with automated monitoring systems that continuously track and adjust the air-fuel ratio. These systems provide real-time data and alerts, helping operators maintain optimal combustion conditions and prevent back-fire.

3. Proper Ignition Timing

Proper ignition timing is another critical factor in preventing back-fire. Faulty or poorly timed ignition systems can cause delayed or premature ignition, leading to back-fire. Regular checks and adjustments ensure that ignition occurs at the right moment, promoting safe and efficient combustion. Additionally, worn or faulty components such as spark plugs, electrodes, or ignition controllers should be replaced as part of routine maintenance. These components are vital for reliable ignition, and their failure can increase the risk of back-fire.

4. Monitoring Boiler Load

Monitoring and managing boiler load is essential to prevent back-fire. Sudden and extreme changes in boiler load can disrupt the combustion process, causing pressure fluctuations that may lead to back-fire. Gradual adjustments to the load help maintain stable combustion conditions. Advanced control systems can automatically adjust fuel and air supply in response to load changes, ensuring stable combustion and preventing back-fire. These systems are particularly useful in dynamic maritime environments where boiler demand can vary significantly.

5. Training and Awareness

Training and awareness among ship engineers and crew are vital for preventing back-fire. Early detection of issues such as irregular flame patterns, unusual noises, or pressure fluctuations can prevent back-fire. Training ensures that the crew can recognize and address these signs promptly. Additionally, conducting regular safety drills helps prepare the crew to handle boiler emergencies effectively. In the event of a back-fire or other boiler-related emergencies, a well-trained crew can respond quickly and efficiently, minimizing risks and ensuring the safety of the vessel and its personnel.

By implementing these measures, maritime operators can significantly reduce the risk of back-fire in marine boilers, ensuring safer and more efficient vessel operations.

Emergency Response to Back-Fire

Despite preventive measures, back-fire incidents may still occur. Here’s how to respond:

- Shut Down the Boiler: Immediately stop the burner to halt fuel supply.

- Ventilate the Boiler Room: Clear any accumulated flammable gases.

- Inspect for Damage: Check burners, fuel lines, and surrounding areas for signs of damage.

- Report and Document: Record the incident and findings for maintenance and safety audits.

- Restart Protocol: Only restart the boiler after thorough inspection and clearance by qualified personnel.

Back-fire in marine boilers is a serious issue that demands attention from maritime engineers and operators. By understanding its causes, implementing preventive measures, and preparing for emergency responses, ships can minimize risks and ensure safe, efficient boiler operations. Regular training and maintenance are key to fostering a safe and secure marine environment.

For further resources and advanced training, explore our maritime education modules tailored for seafarers and marine engineers.