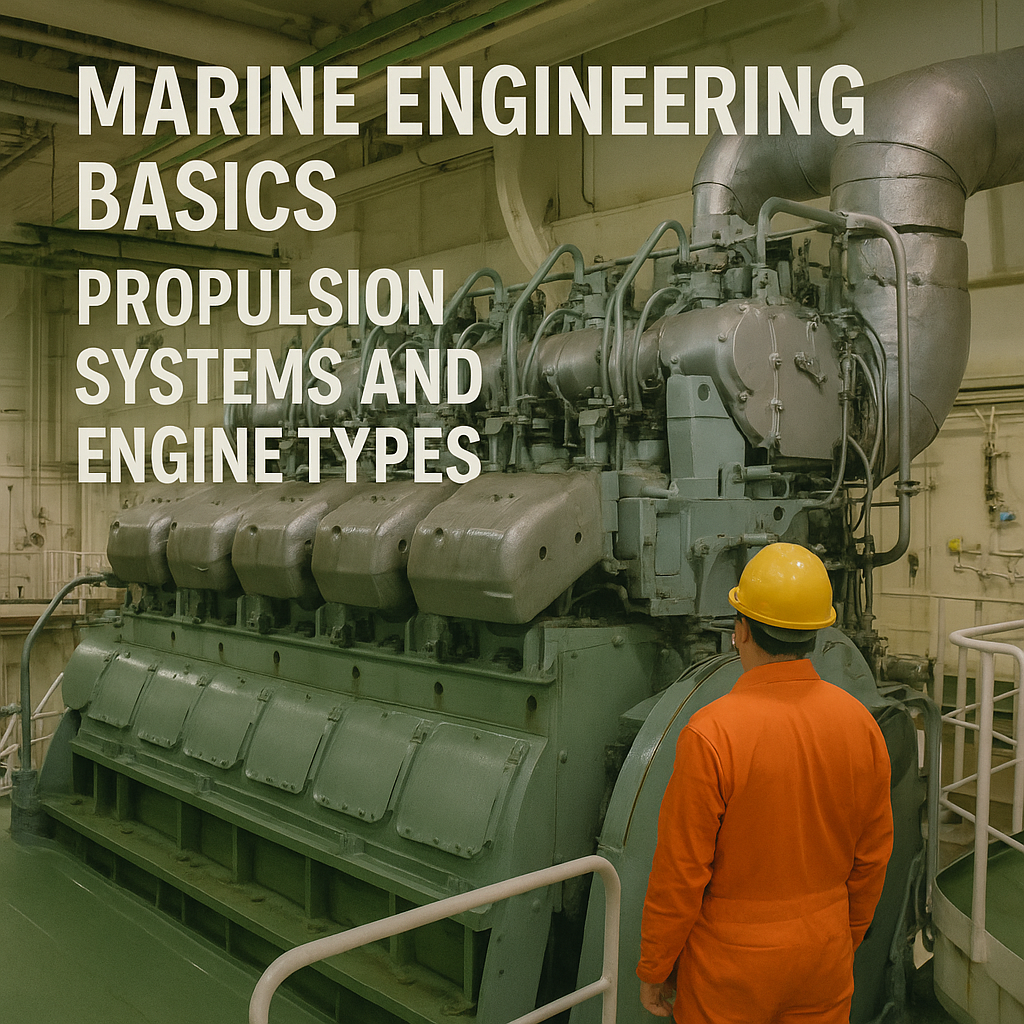

Explore the essential principles of marine engineering, from ship propulsion systems to main engine types. Understand how modern ships move and the technology powering global maritime trade.

Why Marine Engineering Matters in Modern Maritime Operations

Marine engineering forms the beating heart of the maritime industry. Every container vessel crossing the Pacific, every LNG tanker navigating Arctic waters, and every cruise ship gliding through the Caribbean relies on engineering systems to propel, maneuver, and operate safely.

With over 80% of global trade volume carried by sea (UNCTAD, 2023), the reliability and efficiency of propulsion systems are more critical than ever. Marine engineers are not only responsible for machinery but also for integrating new energy sources, meeting stricter emission rules (like IMO 2023 carbon intensity standards), and ensuring vessels can handle modern navigation demands.

Whether you’re a student, a cadet, or a professional looking to refresh your knowledge, this guide breaks down the basics of ship propulsion systems and marine engine types—with real-world examples, recent innovations, and insights from industry experts.

What Is Marine Propulsion?

In simple terms, marine propulsion is how a ship moves through water. It converts energy—usually from fuel—into thrust that pushes the vessel forward.

Traditional propulsion systems are mechanical, relying on a diesel engine connected to a propeller via a shaft. But in the last two decades, electrical and hybrid systems have emerged alongside LNG, methanol, and hydrogen as alternative fuels.

Regardless of design, the goal remains the same: to move the vessel efficiently, safely, and with minimal environmental impact.

–

Main Propulsion Systems in Ships

Conventional Shaft Propulsion

This is the most common system in merchant shipping.

-

How it works: A marine diesel engine turns a crankshaft. This drives the propeller shaft, which rotates the propeller.

-

Fuel type: Heavy fuel oil (HFO), marine gas oil (MGO), or low-sulfur fuel oil (LSFO).

-

Application: Bulk carriers, tankers, container ships.

Example: The Wärtsilä RT-flex96C, used on large container ships, is a two-stroke diesel engine capable of producing over 80,000 kW. It’s one of the most powerful marine engines ever built.

Diesel-Electric Propulsion

Electric propulsion uses diesel generators to produce electricity, which powers electric motors connected to propellers.

-

Advantages: More flexible layout, lower noise and vibration, and efficient at varying speeds.

-

Common in: Icebreakers, naval ships, cruise vessels.

Example: The Royal Navy’s Type 45 destroyers use an integrated electric propulsion system (IEPS), combining gas turbines and diesel engines with electric motors.

Gas Turbine Propulsion

Used in military vessels and some high-speed ferries.

-

Pros: Lightweight, fast acceleration, high power-to-weight ratio.

-

Cons: High fuel consumption and maintenance cost.

Example: The U.S. Navy’s Arleigh Burke-class destroyers feature General Electric LM2500 gas turbines.

Steam Turbine Propulsion (Historic and LNG Application)

-

Historic role: Powered early 20th-century ships like the RMS Titanic.

-

Modern use: Some LNG carriers use steam turbines with boil-off gas (BOG) from LNG cargo.

While steam turbines are being phased out, some vessels still use dual-fuel steam systems for efficiency.

Azimuth Thrusters and Podded Propulsion

Azimuth thrusters rotate 360°, offering superior maneuverability.

-

Types: Mechanical, electric (Azipod® by ABB), or hydraulic.

-

Used in: Cruise ships, offshore support vessels (OSVs), dynamic positioning vessels.

Example: The Queen Mary 2 cruise liner uses electric podded propulsion, enhancing both efficiency and turning radius.

–

Engine Types in Marine Engineering

Marine engines are typically classified by stroke type, fuel type, and function.

Two-Stroke vs Four-Stroke Engines

-

Two-stroke engines: Simple design, high torque, typically used as main propulsion engines in large ships.

-

Example: MAN B&W ME-C series.

-

-

Four-stroke engines: More complex, used in auxiliary power and smaller vessels.

-

Example: Wärtsilä 32 engine for ferries and offshore vessels.

-

Key difference: Two-stroke engines complete a power cycle in one crankshaft revolution, while four-stroke engines need two.

Main Engine vs Auxiliary Engine

-

Main engine: Propels the ship forward. Generally larger and uses HFO.

-

Auxiliary engine (generator engine): Powers onboard equipment and hotel load. Runs on MGO or LSFO.

On modern ships, redundancy is crucial. Multiple auxiliary engines ensure continuous power during main engine maintenance or emergencies.

Dual-Fuel and Alternative Fuel Engines

Driven by IMO’s decarbonization goals, dual-fuel engines that run on both LNG and diesel are gaining traction.

Example: MAN 51/60DF and Wärtsilä 34DF engines offer flexibility in fuel sourcing and reduce SOx and NOx emissions.

Fuel flexibility is critical as regulations tighten. LNG reduces CO₂ emissions by ~20% compared to HFO (DNV, 2023), though methane slip is a concern.

–

Case Study: Propulsion System on a Modern Container Ship

Take the Maersk Triple-E class—designed for energy efficiency, economy of scale, and environmental performance.

-

Main engine: MAN B&W 11S90ME-C9 two-stroke engine.

-

Propulsion: Direct drive to a fixed-pitch propeller.

-

Power output: ~80,000 kW at 80 rpm.

-

Emission reduction: Utilizes exhaust gas economizers and waste heat recovery to improve energy efficiency.

This setup exemplifies the latest marine engineering philosophy: fewer revolutions, bigger propellers, better fuel economy.

Challenges in Modern Marine Propulsion

While technologies have advanced, engineers face increasing demands:

-

Environmental Regulations: IMO 2023 and EU Fit for 55 aim for GHG reduction. Compliance requires engine retrofits, scrubbers, or switching fuels.

-

Fuel Price Volatility: Shifts in global energy markets affect engine operating costs.

-

Maintenance and Diagnostics: Engine wear, cylinder lubrication, and fouling require smart monitoring.

-

Methane Slip in LNG Engines: A known challenge that reduces the climate advantage of LNG.

Solution Pathways: Use of digital twins, predictive maintenance, and real-time emission tracking.

Recent Developments (2020–2025)

The marine propulsion industry is evolving rapidly:

-

Methanol-ready engines: Maersk ordered a fleet of methanol-powered vessels from Hyundai Mipo in 2023.

-

Hybrid-electric systems: Ferries in Norway (e.g., MF Bastø Electric) use battery packs charged by shore power.

-

Ammonia-fueled engines: Wärtsilä and MAN are piloting ammonia propulsion systems as a zero-carbon solution.

Source: DNV Maritime Forecast 2023

FAQ: Marine Engineering and Propulsion

What engine is used in most large commercial ships?

Two-stroke slow-speed diesel engines, like those from MAN B&W or Wärtsilä.

What is the difference between mechanical and electric propulsion?

Mechanical uses a direct shaft from engine to propeller; electric uses generators to power motors.

Are gas turbines used in merchant vessels?

Rarely. They are fuel-intensive and mostly used in military or high-speed crafts.

What’s the future of marine propulsion?

Alternative fuels (LNG, methanol, ammonia), hybrid-electric systems, and AI-assisted diagnostics.

Can ships be fully electric?

Yes, but mostly for short voyages. Battery capacity is a limitation for ocean-going ships.

What is EEDI?

The Energy Efficiency Design Index—an IMO regulation mandating minimum efficiency for new ships.

Why is shaft alignment important?

Poor alignment leads to vibration, wear, and power loss. Precision is crucial for efficiency and safety.

Conclusion: The Engine Room Behind Global Trade

Marine engineering isn’t just about making engines run—it’s about making the world’s trade system move safely, cleanly, and efficiently. From traditional diesel engines to advanced hybrid propulsion systems, the evolution of marine propulsion reflects the industry’s resilience and adaptability.

For students and professionals, staying updated with propulsion technologies is essential—not just for passing exams or job interviews, but for navigating an industry that’s increasingly digital, green, and globally connected.

Whether you’re aboard an LNG tanker, a ferry in Norway, or studying at a maritime academy, the future of propulsion is yours to engineer.