Explore the safety measures, operational logistics, and regional complexities of oil tanker operations in the Persian Gulf. This guide examines regulatory frameworks, modern technologies, and real-world challenges faced by the global tanker industry.

Navigating the World’s Most Strategic Oil Corridor

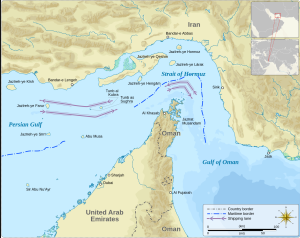

The Persian Gulf is not just a body of water—it’s the economic artery of the global energy supply. With over 30% of the world’s seaborne crude oil passing through the Strait of Hormuz every year, the region’s importance in global shipping and energy security is unparalleled. However, operating oil tankers in this geopolitical hotspot presents unique safety, navigational, and logistical challenges.

From high-density traffic and piracy threats to extreme climate conditions and evolving international regulations, tanker operations in the Persian Gulf demand the highest levels of planning, training, and technological integration. This article explores the critical elements of oil tanker operations in the region, including compliance with IMO safety codes, cargo transfer protocols, and strategies to ensure navigational and environmental security.

Why Tanker Operations in the Persian Gulf Matter in Modern Maritime Trade

The Persian Gulf, bordered by energy giants such as Saudi Arabia, the UAE, Kuwait, and Iran, serves as a loading and transshipment hub for VLCCs (Very Large Crude Carriers) and Aframax tankers supplying oil to Asia, Europe, and North America. According to the U.S. Energy Information Administration (EIA, 2023), over 21 million barrels per day of oil pass through the Strait of Hormuz, making it the most vital chokepoint for global oil trade.

Operational safety in this region is non-negotiable:

-

A single collision or spill could halt global supply chains.

-

Hostile engagements can disrupt operations and spike global oil prices.

-

Mismanagement in cargo transfer or navigation can result in detentions or accidents.

With so much at stake, safe and efficient tanker operations are paramount—not just for shipowners and operators, but for the global economy.

Key Operational Areas: Tanker Navigation, Cargo Transfer, and Port Protocols

Navigational Challenges in the Strait of Hormuz

At its narrowest point, the Strait of Hormuz is only 21 nautical miles wide, with two 2-mile-wide shipping lanes and a buffer zone. Tankers must navigate:

-

Congested lanes used by commercial vessels, naval patrols, and fishing boats

-

High-speed current changes, especially near the Musandam Peninsula

-

GPS spoofing risks reported by Lloyd’s List Intelligence (2022)

To mitigate these, ships rely on:

-

Advanced ECDIS systems and AIS monitoring

-

Regular communications with marine traffic control centers in Oman and UAE

-

Coordination with coalition naval forces (e.g., CMF, USCG)

Cargo Loading at Key Terminals

Major oil terminals in the region include:

- Kharg Island (Iran)

- Ras Tanura (Saudi Arabia)

- Mina Al Ahmadi (Kuwait)

- Jebel Dhanna (UAE)

At these ports, loading procedures are governed by strict protocols:

-

Closed loading using vapor return lines to meet MARPOL Annex VI emissions regulations

-

Real-time monitoring of static electricity build-up, inert gas systems, and load rates

-

Alignment with OCIMF’s Ship Inspection Report Programme (SIRE) for pre-arrival audits

Ballast Operations and MARPOL Compliance

The warm waters of the Gulf make ballast water exchange an ecological concern. Ships must comply with the Ballast Water Management Convention (BWMC) and often use onboard ballast water treatment systems from manufacturers like Alfa Laval or Wärtsilä.

To protect sensitive marine environments:

-

Ballast operations are logged and reported to port state control

-

Environmental officers onboard follow IMO BWM protocols to avoid violations

-

Use of approved neutralization chemicals or UV-based systems is becoming standard

–

Safety Measures and Emergency Preparedness

Navigational Safety Protocols

To minimize risk in high-traffic and geopolitically volatile waters:

-

Ships adopt Transit Corridor Systems guided by Combined Maritime Forces (CMF)

-

Use LRIT (Long-Range Identification and Tracking) for continuous monitoring

-

Tankers are required to submit Advanced Notification Forms (ANF) before entry

Fire and Explosion Risk Management

Given the volatility of crude oil cargo:

-

IGS (Inert Gas Systems) are maintained at positive pressure to avoid oxygen buildup

-

All tanks undergo gas freeing and testing before maintenance or inspection

-

Firefighting systems are SOLAS-compliant, with high-capacity foam monitors and CO₂ suppression systems

Crew Training and STCW Compliance

Crew training is regulated under the STCW Convention, with officers trained in:

-

Advanced Tanker Operations (STCW VI/1 and V/1-1)

-

Emergency shutdown procedures (ESD)

-

Crude Oil Washing (COW) system operation

Refresher training and DP simulator drills are standard in companies operating in high-risk zones.

–

Case Studies: Lessons from Persian Gulf Incidents

MT Front Altair and Kokuka Courageous (June 2019)

Both tankers were attacked near the Gulf of Oman, leading to fires and emergency abandon ship operations. The crews survived, but the incidents triggered:

-

A surge in war risk premiums

-

Increased naval escort requests

-

Reviews of ISPS Code compliance procedures for vessels in the region

MT Sanchi (2018, East of the Gulf area)

Though not directly in the Gulf, the Sanchi incident highlighted:

-

The risks of volatile cargoes like condensate

-

The importance of automated firefighting systems

-

Gaps in AIS and VHF watchkeeping that led to delayed response

These case studies emphasize the importance of real-time threat assessment, robust safety systems, and international coordination.

–

Recent Advancements in Tanker Safety and Efficiency (2020–2025)

-

Smart Tanker Technology: Real-time fuel monitoring, leak detection sensors, and AI-based trim optimization

-

Bridge Decision Support Systems (DSS): Used to reduce human error in tight navigation lanes

-

Automated Mooring Systems at terminals like Ras Laffan and Fujairah reduce accidents during berthing

-

Maritime Domain Awareness (MDA) platforms: Shared among coalition forces for monitoring suspicious maritime activity

According to a 2024 report by IHS Markit, VLCCs equipped with integrated DSS and energy efficiency management systems reduced bunker consumption by up to 12% in congested regions like the Persian Gulf.

Frequently Asked Questions

What are the key safety concerns for tankers in the Persian Gulf?

Navigational congestion, regional conflict, fire risk, and environmental protection are primary concerns.

Are tankers escorted by naval forces?

Often yes, especially during heightened tensions. Naval escorts are coordinated through CMF (Combined Maritime Forces) or regional maritime authorities.

What IMO conventions govern tanker operations in this region?

Key conventions include SOLAS, MARPOL, STCW, and ISPS Code. The Polar Code is not applicable but informs cold-weather readiness for northern-bound vessels.

What ports are most critical for tanker logistics in the Gulf?

Ras Tanura, Mina Al Ahmadi, Jebel Dhanna, and Kharg Island are major oil terminals. Fujairah and Khor Fakkan serve as key bunkering and lay-up hubs.

What type of tankers typically operate here?

VLCCs dominate crude export routes. Aframax and Suezmax tankers are used in inter-Gulf and regional distribution.

How are spills or accidents handled in the Gulf?

Ports operate under OSRO agreements (Oil Spill Response Organizations). Regional spill drills and IMO-level preparedness plans are coordinated through the REMPEC office.

Conclusion: Navigating Complexity with Competence

Operating an oil tanker in the Persian Gulf requires more than just seamanship—it demands strategic navigation, rigorous safety compliance, and an acute awareness of geopolitical and environmental realities.

With evolving technologies, enhanced training standards, and collaborative regional security frameworks, modern oil tanker operations are more resilient than ever. But the margin for error remains razor-thin. From engine room to ECDIS, every system must function flawlessly in this high-stakes maritime theater.

Whether you’re a cadet, fleet manager, or maritime student, understanding tanker logistics in the Persian Gulf equips you with a sharper, safer, and smarter view of one of the world’s most dynamic shipping regions.