Get ahead of your next port state control (PSC) inspection with these top 10 expert tips. Discover how seafarers can avoid detentions, pass inspections smoothly, and stay compliant with international maritime safety standards.

Why Port State Control Inspections Matter in Modern Maritime Operations

In today’s increasingly regulated maritime landscape, Port State Control (PSC) inspections are more than procedural check-ins—they are crucial checkpoints that determine whether your vessel remains operational or ends up detained.

After the Amoco Cadiz sank that year, it was decided to also audit safety and pollution practices. To this end, in 1982 fourteen European countries agreed on the Paris Memorandum of Understanding on Port State Control (Paris MoU) to establish port state control. Currently, 26 European countries and Canada are signatories of Paris MoU. PSC was a reaction to the failure of those flag states – especially flag of convenience states – that had delegated their survey and certification responsibilities to classification societies.

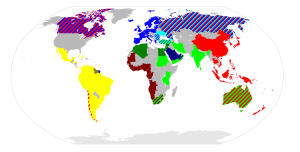

Modeled on the Paris MOU, several other regional MOUs have been signed, including the Tokyo MOU (Pacific Ocean),Acuerdo Latino or Acuerdo de Viña del Mar (South and Central America), the Caribbean MOU,the Mediterranean MOU, the Indian Ocean MOU,the Abuja MOU (West and Central Atlantic Africa), the Black Sea MOU, and the Riyadh MOU (Persian Gulf).

Signatories to the Paris MOU (blue), Tokyo MOU (red), Indian Ocean MOU (green), Mediterranean MOU (dark green), Acuerdo de Viña del Mar (yellow),[1] Caribbean MOU (olive), Abuja MOU (dark red), Black Sea MOU (cyan) and Riyadh MOU (navy).

PSC is the second line of defense in maritime safety, stepping in when flag state enforcement fails. Inspectors acting on behalf of regional agreements like the Paris MoU, Tokyo MoU, or USCG routinely inspect foreign vessels to ensure compliance with key international conventions, including SOLAS, MARPOL, STCW, and the MLC.

Failure to comply doesn’t just lead to detention; it can affect a company’s safety reputation, financial standing, and chartering opportunities. For seafarers, PSC inspections are high-stakes moments—yet success often hinges on preparation, awareness, and communication.

This guide offers 10 essential tips, based on real-world practices and common detainable deficiencies, to help crew members pass inspections with confidence.

1. Master the Basics: Know the PSC Framework

Before preparing for inspections, every officer must understand how PSC operates.

Key Elements:

-

PSC is governed regionally (e.g., Paris MoU, Tokyo MoU).

-

High-risk ships (older vessels, past detentions) are prioritized.

-

PSC inspections can be initial, expanded, or targeted.

Insight: According to Paris MoU data (2023), over 13,000 inspections were conducted, with nearly 3.5% of ships detained for safety-related deficiencies.

2. Ensure All Certificates Are Up-to-Date and Accessible

Outdated or missing documents remain one of the top reasons for vessel detention.

Ensure all certificates are:

-

Valid, with no expired documents onboard.

-

Accessible, preferably in a dedicated folder for quick review.

-

Supported by evidence, such as logbooks, manuals, and maintenance records.

Pro Tip: Conduct a pre-port internal audit 24–48 hours before arrival to verify that certificates such as the Safety Management Certificate (SMC), International Oil Pollution Prevention (IOPP), and Maritime Labour Certificate (MLC) are valid and onboard.

3. Prepare for the Inspector’s First Impressions

PSC inspections often begin with visual impressions. Dirty passageways, cluttered bridge equipment, or unkempt engine rooms signal poor maintenance culture.

Best Practice:

-

Clean and organize high-traffic areas: accommodation, galley, bridge, and engine control room.

-

Welcome inspectors professionally—showing confidence, not defensiveness.

-

Ensure the Master and Chief Engineer are briefed and available.

Analogy: Think of your ship like an aircraft cabin during a surprise aviation inspection—the first 10 minutes set the tone for what follows.

4. Conduct Regular Drills and Log Entries

Inspectors often ask for evidence of recent drills as part of the inspection. They may also observe or request a demonstration.

Required drills include:

-

Fire and abandon ship

-

Man overboard

-

Security and oil spill response

Example: During a 2021 inspection in Antwerp, a tanker was detained because the crew could not demonstrate how to start the emergency fire pump—despite it being technically operational.

5. Test Emergency Systems Before Arrival

PSC inspections focus heavily on operational readiness. Make sure all emergency systems are tested and logged before arriving at port.

Checklist Includes:

-

Emergency lighting

-

Lifeboat engine starts

-

Fire main pressure

-

ECDIS and GMDSS test logs

Stat: According to Tokyo MoU statistics, deficiencies in emergency systems accounted for 12.5% of all detentions in 2022.

6. Show a Strong Safety Management System (SMS)

An effective Safety Management System (SMS) isn’t just paperwork—it must be lived.

What Inspectors Look For:

-

Knowledge of the ship’s SMS among officers and crew

-

Internal audits and corrective actions

-

Awareness of the Designated Person Ashore (DPA)

Tip: During interviews, crewmembers should confidently explain safety procedures, such as enclosed space entry or permit-to-work protocols.

7. Know Your MARPOL Equipment—And Its Records

Environmental compliance is a major PSC focus, particularly under MARPOL.

Common MARPOL issues:

-

Faulty OWS (Oily Water Separator)

-

Incomplete or forged Oil Record Book

-

Poor garbage management or sewage handling

Red Flag: If the OWS doesn’t operate correctly or documentation doesn’t match actual practices, the vessel risks immediate detention.

8. Ensure Crew Competency and Familiarity with Duties

PSC inspectors often interview crew members to check understanding of duties and emergency procedures.

Ensure:

-

All officers have valid STCW certificates.

-

Crew can explain their muster list roles, including lifeboat launching or fire team responsibilities.

-

Ratings are familiar with PPE and safety signage.

Tip: Conduct roleplay drills a few days before inspection to boost confidence and address weak areas.

9. Maintain Accurate and Transparent Recordkeeping

Whether it’s ballast water exchange, lifeboat maintenance, or oil transfers, proper log entries are essential.

Must-Have Logs:

-

Bridge and engine logbooks

-

GMDSS log

-

Maintenance schedules

-

Non-conformity reports

Warning: Missing or backdated entries are red flags. Keep documentation real-time, clean, and consistent with operational reality.

10. Conduct a Pre-Arrival Internal PSC Audit

The best way to avoid unpleasant surprises is through self-inspection using PSC checklists.

Steps:

-

Use regional MoU checklists (e.g., Paris MoU Inspection Checklist PDF).

-

Assign responsibility to departments (deck, engine, galley).

-

Hold a final briefing meeting with all department heads.

Pro Tip: Appoint a PSC liaison officer onboard—someone who coordinates inspector requests and ensures a smooth flow of communication.

Real-World Case Study: The Detention of MV Greenstar (2022)

During a routine PSC inspection in Rotterdam, the MV Greenstar was detained for multiple deficiencies:

-

Inoperative emergency lighting

-

Incomplete Oil Record Book entries

-

Crew unable to explain muster station duties

Despite being a modern ship, these lapses cost the company five days of off-hire time, legal penalties, and damage to its safety profile on the Paris MoU White List.

FAQ: Port State Control Inspections

Q1: How often do PSC inspections occur?

A: Frequency depends on ship risk profile, past history, flag, and type. High-risk vessels may face multiple inspections annually.

Q2: Can a ship refuse a PSC inspection?

A: No. Refusal may result in denial of port entry or automatic detention.

Q3: What is the most common reason for PSC detention?

A: Fire safety violations, outdated certificates, and malfunctioning emergency equipment.

Q4: How long does a typical inspection take?

A: 3–6 hours for standard inspections; expanded inspections may take longer.

Q5: What is an expanded inspection?

A: A deeper inspection for high-risk vessels, covering structural integrity, machinery, and more.

Q6: Who conducts PSC inspections?

A: Authorized inspectors from the port state’s maritime authority.

Q7: Can PSC inspection results affect future operations?

A: Yes. Repeated detentions can place a vessel on a black list, impacting chartering and insurance rates.

Conclusion

Port State Control inspections are an essential, unavoidable part of global maritime operations. But they don’t have to be adversarial or nerve-wracking. With the right preparation, transparent documentation, and well-trained crew, passing a PSC inspection becomes a demonstration of professional excellence—not a hurdle to fear.

Call to Action: Want more checklists, PSC case studies, or downloadable audit tools? Visit our Maritime Compliance Resource Center for everything you need to stay inspection-ready.

References

-

Paris MoU. (2023). Annual Report on Port State Control. https://www.parismou.org

-

Tokyo MoU. (2022). Summary of Detentions and Deficiencies. https://www.tokyo-mou.org

-

International Maritime Organization (IMO). (2020). SOLAS and MARPOL Requirements. https://www.imo.org

-

European Maritime Safety Agency (EMSA). (2023). Maritime Safety Statistics. https://emsa.europa.eu