Ship machinery and systems form the backbone of marine operations, enabling vessels to perform essential functions such as propulsion, power generation, navigation, and cargo handling. Understanding these systems is crucial for cadets, engineers, and maritime professionals, as well as enthusiasts seeking insight into the heart of marine engineering.

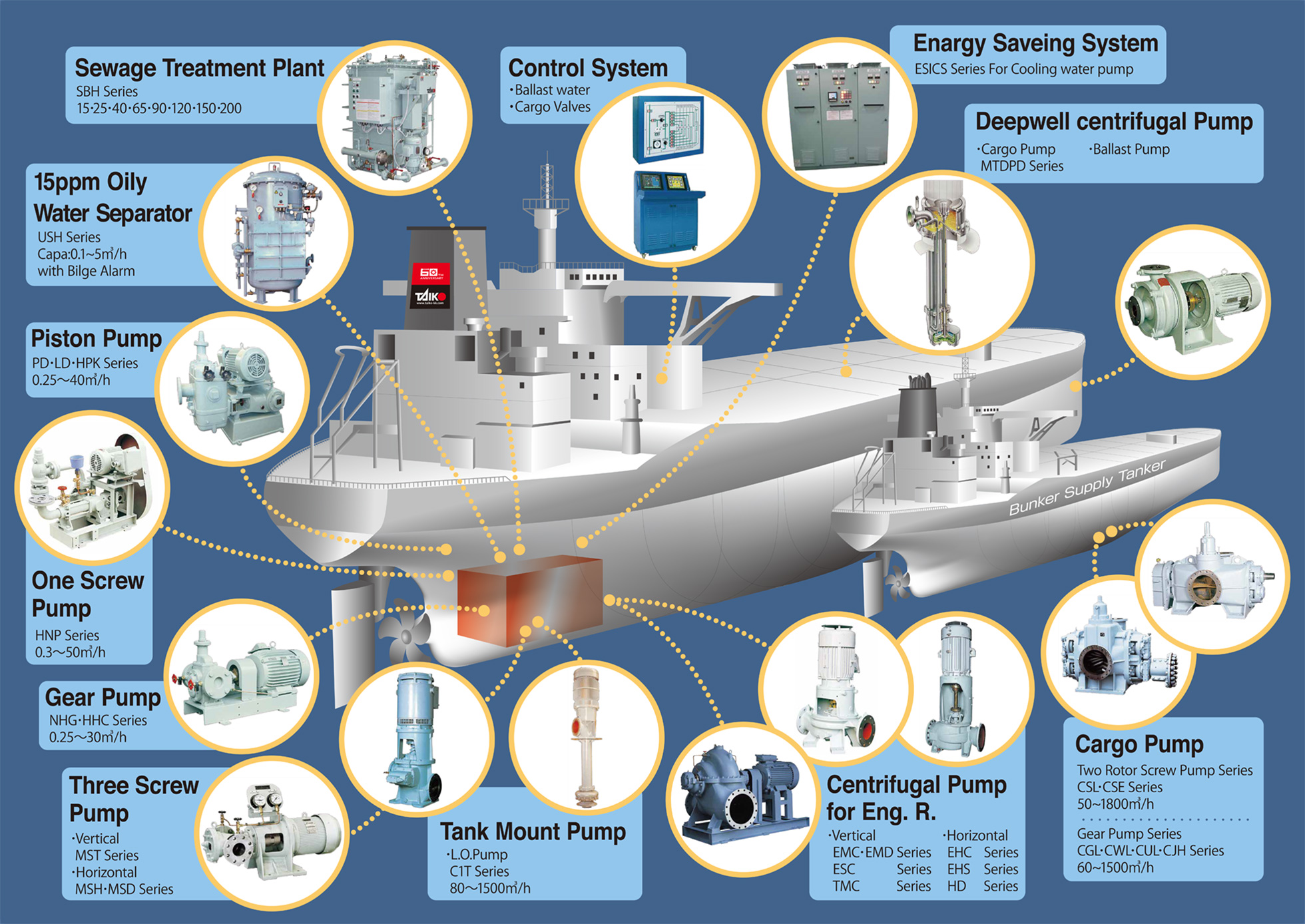

Ship machinery refers to the mechanical and electrical equipment onboard a vessel that supports its operation, propulsion, and auxiliary services. This includes main engines, generators, pumps, boilers, compressors, and associated control systems. The purpose of ship machinery is to ensure a vessel’s movement, safety, habitability, and operational efficiency at sea.

- Main Propulsion System – Comprising diesel engines, gas turbines, or electric drives, this system propels the ship.

- Power Generation and Distribution System – Generates and distributes electrical energy throughout the vessel.

- Steering System – Includes rudders, hydraulic pumps, and steering gears.

- Bilge and Ballast Systems – Handle water ingress and manage vessel stability.

- Fresh Water and Sewage Systems – Provide potable water and waste treatment.

- Firefighting and Safety Systems – Ensure onboard safety through detection and suppression tools.

- Navigation and Communication Systems – Include radar, GPS, AIS, and radios.

- Propulsion System – Converts fuel into thrust to move the ship.

- Electrical System – Powers lighting, automation, and equipment.

- Fuel System – Supplies fuel to the engines.

- Lubrication System – Reduces friction and wear in engines.

- Cooling System – Maintains optimal temperature for engine operations.

- Main Engine (e.g., MAN B&W or Wärtsilä) – Converts fuel into mechanical power.

- Auxiliary Engines – Generate electrical power.

- Air Compressors – Supply compressed air for starting engines and operating tools.

- Pumps – Circulate liquids like fuel, ballast water, and lubricants.

- Boilers – Produce steam for heating and auxiliary needs.

- Purifiers – Clean oil and fuel by removing water and contaminants.

- Operate machinery efficiently.

- Diagnose and troubleshoot malfunctions.

- Ensure compliance with maritime regulations.

- Enhance ship safety and environmental protection.

Operating ship machinery presents challenges such as frequent breakdowns caused by harsh marine environments like saltwater corrosion and extreme weather. The complexity of these systems often makes diagnosing issues difficult, requiring advanced technical expertise. Regular maintenance is essential but demanding, as it ensures reliability and prevents failures. Furthermore, evolving technology necessitates continuous learning to keep up with advancements and maintain operational efficiency.

- Increased use of hybrid propulsion and battery systems.

- Integration of smart maintenance technologies (e.g., IoT sensors).

- Focus on energy-efficient and eco-friendly systems.

- Adoption of automation and remote diagnostics.

Additional Resources

- DNV – Ship Machinery Efficiency

- ABS Rules for Building and Classing

- ScienceDirect: Ship Machinery Research

maritimeducation.com

maritimeducation.com

best maritimeducation.com

best maritimeducation.com

best maritimeducation.com

best maritimeducation.com

best maritimeducation.com

best maritimeducation.com

maritimeducation.com

best maritimeducation.com

best maritimeducation.com

best maritimeducation.com

best maritimeducation.com

best maritimeducation.com

best maritimeducation.com

best maritimeducation.com

best maritimeducation.com

best maritimeducation.com

maritimeducation.com

Ship Machinery and Systems: An Essential Guide for Maritime Learners – Maritime Education

Ship Machinery and Systems: An Essential Guide for Maritime Learners – Maritime Education

Ship Machinery and Systems: An Essential Guide for Maritime Learners – Maritime Education

Ship Machinery and Systems: An Essential Guide for Maritime Learners – Maritime Education

Ship Machinery and Systems: An Essential Guide for Maritime Learners – Maritime Education

Ship Machinery and Systems: An Essential Guide for Maritime Learners – Maritime Education

Ship Machinery and Systems: An Essential Guide for Maritime Learners – Maritime Education

Ship Machinery and Systems: An Essential Guide for Maritime Learners – Maritime Education

Ship Machinery and Systems: An Essential Guide for Maritime Learners – Maritime Education

To the maritimeducation.com owner, Excellent work!

Dear maritimeducation.com webmaster, Your posts are always well-received by the community.

Hi maritimeducation.com admin, Your posts are always informative.

maritimeducation.com