Bunkering, the process of transferring fuel to a vessel, is a cornerstone of maritime logistics. For dual fuel ships that operate on both Liquefied Natural Gas (LNG) and Diesel Oil (DO), the process demands even greater precision and adherence to safety protocols. This article delves into the intricacies of bunkering dual fuel ships, focusing on the procedures, safety considerations, and regulatory frameworks that govern these critical operations.

Understanding Dual Fuel Systems

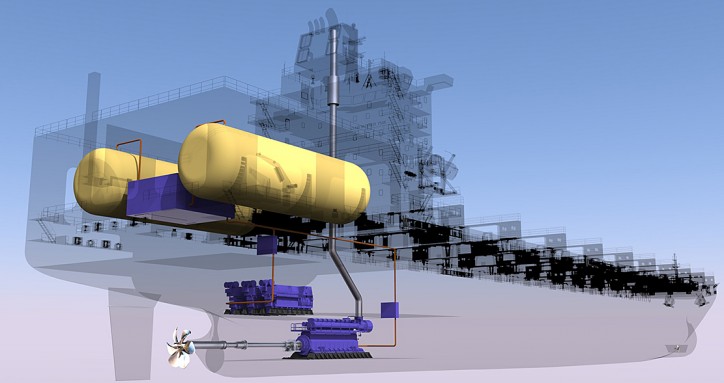

Dual fuel ships are engineered to operate on two types of fuel: LNG and Diesel Oil. LNG, known for its lower emissions and reduced environmental impact, serves as a cleaner alternative to conventional marine fuels. Diesel Oil, on the other hand, provides the reliability and flexibility needed to ensure operational continuity, particularly in regions where LNG infrastructure may be limited.

The decision to use one fuel over the other often hinges on factors such as:

- Availability: LNG bunkering infrastructure is expanding but remains concentrated in key ports.

- Cost: Fluctuations in fuel prices may make one fuel more economical than the other.

- Regulatory Compliance: Emission control area (ECA) regulations and global environmental standards influence fuel selection.

Bunkering Procedures for Dual Fuel Ships

The bunkering process for dual fuel ships is multifaceted, requiring careful planning and execution to ensure safety and efficiency. Below is a breakdown of the key steps involved:

Preparation

- Weather and Tide Assessment: The ship’s Master must evaluate weather conditions and tidal movements to ensure safe and stable operations. Adverse conditions may necessitate delaying bunkering operations.

- Safety Zone Establishment: A safety perimeter is marked around the bunkering site. This area is treated as an EX-classified zone due to the flammable and cryogenic nature of LNG.

- Equipment Inspection: All bunkering equipment, including hoses and couplings, must be inspected for functionality and integrity.

Connection

- Hose and Coupling Setup: Quick Connect/Disconnect (QCDC) couplings and cryogenic transfer hoses are employed to facilitate LNG transfer while minimizing risks of leaks and spills.

- Vapor Return Line Connection: When available, a vapor return line is connected to manage boil-off gas emissions during the transfer, maintaining environmental and operational safety.

Transfer Operation

- Monitoring: Tank levels are closely monitored to prevent overfilling. The use of automatic shutoff systems adds an extra layer of safety.

- Continuous Communication: Clear and uninterrupted communication between the vessel and the bunker supplier is maintained to coordinate all stages of the operation and respond quickly to any anomalies.

Completion

- Hose Draining and Inerting: After fuel transfer, hoses are drained of any residual LNG and purged with inert gas to prevent vaporization.

- Final Checks: A comprehensive inspection ensures that all connections are properly secured and that the fuel quantity delivered aligns with agreed-upon figures.

Safety Considerations in Dual Fuel Bunkering

Bunkering dual fuel ships involves unique hazards that necessitate robust safety measures:

- Cryogenic Risks: LNG is stored at an ultra-low temperature of -162°C, making proper handling critical to avoid frostbite or cryogenic burns. All personnel must wear appropriate Personal Protective Equipment (PPE), including insulated gloves and face shields.

- Leakage Prevention: The use of dry-break couplings significantly reduces the risk of leaks during hose connection and disconnection. Additionally, spill containment equipment must be readily available to address accidental releases.

- Emergency Preparedness: Emergency Shut Down (ESD) systems are crucial for halting operations immediately in the event of a malfunction. Regular emergency drills should be conducted to ensure crew readiness.

Regulatory Framework for Bunkering Operations

Compliance with international and national regulations is paramount for safe and efficient bunkering:

IGF Code Compliance: The International Code of Safety for Ships Using Gases or Other Low-flashpoint Fuels (IGF Code) sets rigorous safety standards for LNG-powered vessels. This includes requirements for fuel tank positioning, safety distances, fire protection measures, and operational protocols.

In addition to the IGF Code, maritime authorities in specific regions may impose supplementary regulations tailored to local conditions. Operators must stay informed and comply with these requirements to avoid penalties or delays. Crew members involved in LNG bunkering must undergo specialized training to ensure they are equipped to handle the complexities of dual fuel operations.

Emerging Trends in Dual Fuel Bunkering

As the maritime industry transitions towards cleaner energy solutions, the role of dual fuel ships is becoming increasingly prominent. Innovations such as automated bunkering systems, enhanced LNG storage technology, and the integration of renewable energy sources are shaping the future of fuel transfer operations. Additionally, the expansion of LNG bunkering infrastructure worldwide is making it more accessible, further encouraging the adoption of dual fuel technology.

Bunkering dual fuel ships is a sophisticated process that combines advanced technology, meticulous planning, and strict adherence to safety and regulatory standards. As the maritime industry embraces cleaner fuels and tighter environmental regulations, the ability to conduct safe and efficient bunkering operations will be critical for maintaining compliance and ensuring the sustainable growth of global shipping.

Dr.Reza Karimpour