Shipboard electrical engineering plays a crucial role in the operation and safety of modern merchant vessels. Engineering officers are responsible for overseeing the generation, distribution, and control of electrical power onboard ships. They must also maintain a wide range of electrical equipment and ensure the safe operation of both high and low voltage systems. In this chapter, we will explore the key aspects of shipboard electrical engineering, including power generation, electrical distribution, electric motors and generators, high-voltage safety, and the maintenance of electrical systems.

Power Generation Systems on Ships (AC and DC Systems)

Shipboard electrical systems are powered by onboard generators, which produce the electricity needed to run essential machinery, navigation systems, lighting, and other equipment. Power generation systems can operate on alternating current (AC) or direct current (DC), although AC systems are more common on modern ships.

- Diesel Generators

Diesel generators are the most common source of electrical power on ships. These generators consist of a diesel engine coupled to an alternator, which converts mechanical energy into electrical energy. Depending on the size of the ship, multiple generators may be installed to ensure redundancy and balance electrical loads across different operating conditions.

Engineering officers must ensure that diesel generators are operating efficiently, performing routine checks on fuel consumption, load distribution, and mechanical wear. Regular maintenance includes oil changes, fuel filter replacements, and cooling system inspections to prevent overheating and ensure continuous power supply. - Emergency Power Generation

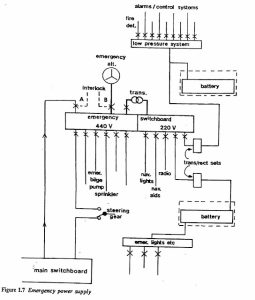

Ships are also equipped with emergency generators, which provide backup power in case of a failure in the main power generation system. These emergency systems are typically powered by small diesel engines or batteries and are essential for maintaining critical systems, such as navigation equipment, communication systems, and emergency lighting.

Engineering officers are responsible for ensuring that emergency power systems are regularly tested and fully functional, especially in challenging operational environments or during inspections by port state authorities. - Shore Power Connections

In port, many ships use shore power connections to reduce fuel consumption and emissions. Shore power allows the ship to draw electricity from a land-based source, eliminating the need to run diesel generators while docked. Engineers must oversee the connection and disconnection of shore power, ensuring proper synchronization and voltage matching to avoid damaging onboard electrical systems.

Electrical Distribution Networks

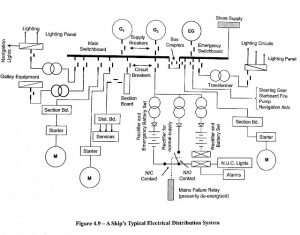

Electrical distribution networks onboard ships are responsible for delivering electricity from the generators to various systems and equipment throughout the vessel. A well-maintained distribution system is essential for ensuring that power is reliably supplied to all parts of the ship.

- Main and Emergency Switchboards

The main switchboard is the central hub of a ship’s electrical distribution system. It controls the distribution of power from the generators to the ship’s electrical circuits. Switchboards are equipped with protective devices, such as circuit breakers and fuses, to prevent overloading or short circuits, which can lead to power outages or equipment damage.

In addition to the main switchboard, ships have an emergency switchboard, which controls the distribution of power from the emergency generator to critical systems in the event of a main power failure. Engineering officers must ensure that both switchboards are inspected regularly, and any faults are addressed promptly to avoid disruptions. - Power Distribution Panels

Power distribution panels are located throughout the ship, supplying electricity to various systems, such as lighting, navigation equipment, and auxiliary machinery. Engineering officers must monitor the distribution panels to ensure that electrical loads are properly balanced and that individual circuits are functioning correctly. Overloading or failure of a distribution panel can lead to equipment malfunction or fire hazards.

Electric Motors, Generators, and Transformers

Electric motors, generators, and transformers are fundamental components of a ship’s electrical system, powering everything from propulsion to auxiliary equipment.

- Electric Motors

Electric motors are used extensively on ships to drive pumps, fans, winches, and other machinery. These motors operate by converting electrical energy into mechanical energy. Engineering officers must maintain these motors by ensuring proper lubrication, monitoring for overheating, and inspecting for signs of wear, such as bearing failure or insulation degradation.

Induction motors and synchronous motors are the most common types found on ships. Officers must be familiar with both types, understanding their respective advantages and troubleshooting techniques. - Generators

In addition to diesel-driven generators, ships may also use shaft generators, which are driven by the main engine’s propulsion shaft to produce electrical power. Shaft generators are often used during sailing to reduce reliance on auxiliary diesel generators, improving fuel efficiency. Engineering officers must monitor the operation of shaft generators and ensure they are synchronized correctly with the main electrical grid to avoid fluctuations in power supply. - Transformers

Transformers are used to step up or step down the voltage levels in a ship’s electrical system, allowing for efficient transmission of electricity and safe operation of equipment. For example, high-voltage electricity generated by the main generators is transformed into lower voltages suitable for use in lighting systems or other auxiliary equipment.

Transformers must be regularly inspected for signs of overheating or insulation failure, and any issues should be addressed immediately to prevent power outages or equipment damage.

High Voltage Safety on Ships

Modern ships, especially large vessels such as tankers and container ships, often use high voltage (HV) systems to distribute power more efficiently over long distances. High voltage systems, typically defined as operating at voltages above 1,000V, pose significant safety risks, and engineering officers must be properly trained in high voltage operations.

- High Voltage Safety Procedures

Working with high voltage systems requires strict adherence to safety procedures to prevent accidents such as electric shock, arc flash, or equipment damage. Ship engineering officers must be familiar with lockout/tagout (LOTO) procedures, which ensure that high voltage systems are de-energized and secured before maintenance work is performed. Officers must also wear appropriate personal protective equipment (PPE), such as insulated gloves and face shields, to minimize the risk of injury. - High Voltage Testing and Maintenance

Regular testing and maintenance of high voltage systems are essential for preventing failures. Engineering officers must conduct insulation resistance tests and dielectric strength tests to ensure that high voltage cables and switchgear are in good condition. High voltage transformers, circuit breakers, and busbars should be inspected regularly for signs of wear, corrosion, or contamination. Any faults detected during testing should be repaired promptly to avoid potentially catastrophic system failures.

Maintenance of Electrical Equipment and Fault Finding

Electrical systems on ships are exposed to harsh conditions, including vibration, temperature fluctuations, and saltwater corrosion. Regular maintenance of electrical equipment is necessary to ensure reliable operation and prevent unexpected failures.

- Routine Inspections and Preventive Maintenance

Engineering officers are responsible for performing routine inspections of electrical systems, identifying potential issues before they lead to equipment failure. Preventive maintenance tasks include cleaning switchboards, checking electrical connections for looseness or corrosion, and replacing worn or damaged components. Maintaining detailed records of maintenance activities helps engineers track equipment performance and plan future maintenance work. - Troubleshooting and Fault Finding

Electrical faults can cause serious operational issues on board a ship, leading to system failures or even fires. Engineering officers must be skilled in troubleshooting and fault finding techniques to quickly identify the source of electrical problems.

Common electrical faults include short circuits, ground faults, and open circuits. Officers use tools such as multimeters, megohmmeters, and thermal imaging cameras to diagnose electrical problems and identify areas of overheating, insulation failure, or excessive current draw. Once the fault is located, repairs should be made promptly to restore the electrical system to normal operation.

Conclusion

Shipboard electrical engineering is a critical discipline that ensures the safe and efficient operation of a ship’s power systems. Engineering officers must have a comprehensive understanding of power generation, distribution, and electrical safety to manage the complex electrical infrastructure on modern vessels. Through regular maintenance, fault detection, and adherence to safety protocols, engineers can prevent electrical failures and ensure the reliability of critical systems onboard. With advancements in high voltage technology, automation, and electrical efficiency, shipboard electrical engineering will continue to evolve, requiring officers to stay current with new technologies and industry standards.

Thank you.