Electrical systems are crucial for the safe and efficient operation of ships. From navigation equipment to propulsion systems and lighting, the integrity of electrical components directly impacts a ship’s performance and safety. One of the most essential tools used to ensure the health and reliability of these electrical systems is the Megger tester. The Megger test, also known as an insulation resistance test, plays a pivotal role in identifying issues related to insulation breakdown and other electrical faults on ships.

In this article, we’ll explore what a Megger test is, how the Megger tester works, and why this testing procedure is particularly important for ships.

What is a Megger Test?

The Megger test is a method used to measure the insulation resistance of electrical components and systems. It is named after the company Megger, which manufactures the equipment used for such tests, but the term is often used generically to refer to any insulation resistance testing.

Insulation in electrical systems is vital for preventing leakage currents, which can lead to short circuits, electrical fires, or even electrocution. Over time, insulation materials can degrade due to exposure to moisture, heat, chemicals, or physical wear and tear. A Megger test is performed to evaluate the condition of this insulation by applying a high-voltage direct current (DC) to an electrical circuit and measuring the resulting resistance.

- High resistance indicates good insulation.

- Low resistance suggests that the insulation may be breaking down, potentially allowing leakage currents, which can be dangerous.

Why is Insulation Resistance Important?

Electrical insulation is designed to contain electrical currents within the wiring or equipment. If insulation becomes weak or damaged, electricity can escape, leading to:

- Electrical faults.

- Equipment malfunction.

- Risk of fire or shock.

- Reduced efficiency and increased energy consumption.

A Megger test helps detect these potential issues early, allowing for preventive maintenance and repairs before a failure occurs.

–

How Does a Megger Tester Work?

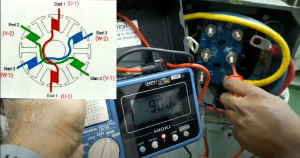

A Megger tester is a handheld device that generates high-voltage DC, typically between 250 volts and 5,000 volts, depending on the rating of the system or equipment being tested. The Megger tester applies this voltage across the insulation material and measures the resistance.

Steps in Conducting a Megger Test:

- Isolate the Equipment: Before performing the test, the electrical equipment or circuit being tested must be isolated from the power source and any other live circuits. Safety precautions are critical to avoid damaging sensitive electronics or causing personal injury.

- Connect the Megger Tester: The Megger tester is connected to the equipment or wiring. Typically, one lead is connected to the conductor, and the other lead is connected to the insulation material or ground.

- Apply Test Voltage: The tester applies a high DC voltage to the circuit, and the test begins. This voltage stresses the insulation to reveal any potential weaknesses or breakdowns.

- Measure Insulation Resistance: The tester measures the resulting current flow and calculates the insulation resistance in ohms (Ω). A higher resistance value indicates better insulation.

- Analyze Results: The measured resistance is compared to standard values or historical data to assess whether the insulation is within acceptable limits or if maintenance is required.

credit: https://www.northshorecommercialdoor.com/product/bd-loops-bd-megger-testing-meter/

Interpreting Megger Test Results

- High Resistance (in the Megohm range or higher): Indicates healthy insulation.

- Moderate Resistance: May indicate that insulation is deteriorating, and further investigation or replacement may be necessary.

- Low Resistance: Indicates damaged or insufficient insulation, requiring immediate attention and repair.

–

The Role of the Megger Test on Ships

Ships operate in harsh and variable environments where electrical systems are exposed to a wide range of factors that can degrade insulation, such as saltwater, humidity, temperature fluctuations, and mechanical vibrations. Regular testing of electrical insulation is critical for the following reasons:

1. Preventing Equipment Failures :Electrical equipment on ships, such as motors, transformers, switchboards, and generators, relies on good insulation to function properly. Degraded insulation can lead to equipment failures, causing operational disruptions or potentially catastrophic failures at sea. A Megger test helps identify potential faults before they lead to major issues.

2. Safety Assurance: Electrical faults, including short circuits and ground faults, are a significant safety risk on ships. Faulty insulation can expose personnel to the risk of electrical shock, fires, and explosions. Performing regular Megger tests helps ship operators ensure that their electrical systems are safe and compliant with maritime safety regulations.

3. Maintaining Compliance with Maritime Regulations:Ships are subject to strict safety and operational standards established by international bodies such as the International Maritime Organization (IMO), Classification Societies, and various national authorities. Regular Megger testing of electrical equipment is often required to ensure compliance with these standards. Ships must demonstrate that their electrical systems are safe, reliable, and capable of withstanding the harsh marine environment.

4. Optimizing Maintenance Schedules:Megger tests are a key part of a ship’s preventive maintenance program. By regularly testing the insulation of critical electrical equipment, ship operators can identify components that are likely to fail and plan repairs or replacements during scheduled maintenance periods. This proactive approach reduces the risk of unexpected breakdowns and minimizes downtime.

5. Protecting Sensitive Electronic Systems:Modern ships are equipped with sophisticated electronic navigation, communication, and automation systems. These systems are highly sensitive to electrical faults, and insulation breakdowns can cause significant damage or disruption. Regular Megger testing of wiring and equipment helps to protect these systems from the effects of insulation failures.

6. Extending Equipment Lifespan:Electrical equipment is a significant investment for ship operators. Megger testing helps ensure that this equipment remains in good working condition, prolonging its lifespan and reducing the need for costly replacements. By catching potential insulation issues early, shipowners can avoid major repair expenses and maintain operational efficiency.

–

Common Applications of Megger Testing on Ships

1. Generators and Motors

Generators and electric motors are vital components on ships, powering everything from propulsion systems to auxiliary equipment. Insulation breakdown in these components can lead to overheating, inefficiency, and equipment failure. Regular Megger testing ensures the insulation of windings and cables in these devices remains intact.

2. Transformers

Transformers onboard ships step up or step down voltage for various applications. Insulation resistance testing ensures that the transformer’s windings are not compromised, which could lead to dangerous arcing, shorts, or even transformer failure.

3. Switchboards

Shipboard switchboards are responsible for distributing electrical power to various systems. Testing the insulation of switchboard components ensures that there are no faults that could interrupt power supply or cause electrical accidents.

4. Cabling and Wiring

Cables on ships are often exposed to moisture, salt air, and physical wear, making them particularly susceptible to insulation damage. Testing the insulation resistance of cables ensures they can safely conduct electricity without leakage, reducing the risk of faults or fires.

5. Navigation and Communication Equipment

Navigational systems, such as radar and GPS, as well as communication systems like radios and satellite links, are critical for a ship’s safe operation. Insulation resistance testing helps protect these systems from electrical faults, ensuring they operate reliably in all conditions.

———————————————————————————————————————————————————————————————————————————

The Megger test is an essential tool in maintaining the safety, reliability, and performance of a ship’s electrical systems. By regularly conducting insulation resistance tests, ship operators can detect and address potential issues before they lead to equipment failures or safety hazards. This not only enhances operational efficiency but also ensures compliance with maritime regulations and protects the well-being of crew members and passengers.

As ships become more reliant on complex electrical and electronic systems, the importance of regular Megger testing will only continue to grow. By incorporating these tests into routine maintenance schedules, shipowners can significantly reduce risks, extend the lifespan of critical equipment, and maintain smooth, trouble-free operations at sea.