Fire pumps on ships are essential components of a ship’s firefighting system, designed to assist the crew in combating emergency fire situations. These pumps, commonly referred to as Marine FiFi Pumps, are vital for ensuring adequate water and foam supply under sufficient pressure to suppress onboard fires. Under the latest SOLAS (Safety of Life at Sea) Convention regulations and the updated Fire Safety Systems (FSS) Code, stringent standards have been set for fire pump types, arrangements, and performance requirements to ensure the highest level of fire protection onboard.

Fire Pump Types and Requirements

1- Main Fire Pumps

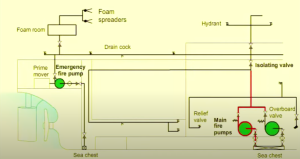

Main fire pumps, typically centrifugal in nature due to their high flow capacity, are the primary firefighting pumps used during fire emergencies. Located in the ship’s engine room, they are electrically driven to ensure reliability and can be operated from multiple points on the ship, including the fire control station, engine control room, and bridge. These pumps are connected to the fire main, which distributes water across the vessel through various firefighting hydrants.

-

- Configuration: Main fire pumps are generally positioned near other essential ship systems like the general service and ballast pumps, often sharing interconnected pipelines for efficiency. However, the use of fire pumps for non-oil cargo or service functions is strictly prohibited, with changeover arrangements needing approval from the relevant authorities.

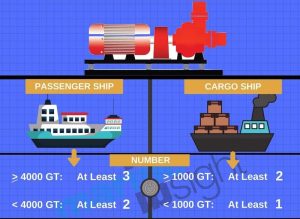

- Redundancy: The SOLAS regulations require that all ships be equipped with at least two independent fire pumps, ensuring redundancy in the event one pump fails. For larger ships, such as passenger and cargo ships, the required number of pumps increases based on the ship’s gross tonnage (GT). For instance, passenger ships below 4000 GT must have at least two independent pumps, while those exceeding 4000 GT must have a minimum of three pumps. Cargo ships above a certain size follow similar requirements.

Located typically in the ship’s engine room, main fire pumps are electrically driven, ensuring high reliability. They often sit near the general service and ballast pumps, with lines interconnected to the fire main, sometimes doubling as general service and fire pumps. However, they are strictly for non-oil pumping, with changeover arrangements for general service use requiring administration approval.

2-Emergency Fire Pumps

The emergency fire pump is a critical component for ships to ensure firefighting capabilities in the event that the main fire pumps become disabled, such as during engine room flooding or electrical failure.

- Location and Power Source: As mandated by SOLAS Chapter II-2, Regulation 4, emergency fire pumps must be installed outside the engine room to ensure continued operability even if the engine room is compromised. These pumps are often driven by a diesel engine or powered by the ship’s emergency generator system. On passenger ships exceeding 1000 GT and cargo ships above 2000 GT, emergency fire pumps are mandatory, and their capacity must be adequate to maintain sufficient firefighting pressure even in emergency situations.

- Backup Water Source: Emergency fire pumps are designed to provide an alternative water supply to the fire main, ensuring that the firefighting system remains fully functional despite any failure in the main pumping system.

Operating Fire Pumps – Flexibility and Accessibility

SOLAS places significant emphasis on the operational flexibility of fire pumps. During an emergency, rapid response and accessibility to firefighting systems are paramount, which is why fire pumps are operable from multiple locations across the vessel. This includes the:

- Bridge

- Fire control station

- Engine control room

Having multiple control points ensures that the firefighting pumps can be activated and operated even if certain areas of the ship become inaccessible or unsafe. This operational redundancy is critical for maintaining firefighting capabilities in dynamic and dangerous situations.

Routine checks and maintenance are essential for ensuring fire pump readiness, involving bearing lubrication, temperature monitoring, gland packing conditions, and mechanical seal integrity. Operational tests, particularly during emergency drills, are crucial for verifying functionality. Fire pump pipelines, typically galvanized to resist seawater corrosion, require careful handling to maintain integrity. In cold conditions or during periods of disuse, additional precautions, like draining to prevent freezing, are necessary.

SOLAS FSS Code – Specific Requirements

The FSS Code, incorporated within the SOLAS framework, establishes more detailed and technical requirements for fire pumps on ships. Key areas of regulation include:

- Pump Capacity: The FSS Code requires that the total combined capacity of fire pumps must be capable of producing a minimum flow rate of water for firefighting operations. The exact capacity is determined based on the ship’s size and type, with larger vessels required to have higher water discharge rates.

- Pressure Requirements: The water pressure delivered by the fire pumps to the fire main must be sufficient to provide effective firefighting capabilities throughout the ship, even at the highest point or furthest hydrant. This pressure must remain consistent, and pumps must be capable of maintaining it for extended periods.

- Hydrant Accessibility: The fire hydrant system, fed by the fire pumps, must be designed so that every part of the ship can be reached with a single firefighting hose connected to the nearest hydrant. The ship’s layout, including fire zones and compartmentalization, is taken into account to ensure complete coverage.

Number and Arrangement of Fire Pumps

The required number of fire pumps and their arrangement on a vessel depends on its size and type. Under SOLAS and FSS requirements:

- Passenger ships: Passenger ships over 4000 GT must have at least three independent fire pumps. Smaller passenger vessels, such as those under 4000 GT, are required to have a minimum of two fire pumps.

- Cargo ships: Cargo ships follow a similar rule, with larger vessels requiring additional pumps to ensure adequate firefighting coverage. The capacity of these pumps must exceed that of other ship systems like bilge pumps, ensuring that firefighting efforts can take precedence over routine maintenance operations.

Credit: Adapted from Marineinsight.

Modern Developments

Recent updates to the FSS Code highlight the importance of ensuring fire pumps and their associated systems are tested regularly and maintained in peak working condition. Emerging technologies, such as remote monitoring systems and automated fire pump testing, are now being explored to further enhance onboard safety. Furthermore, ships are increasingly being equipped with advanced fire suppression systems, including foam and CO2 systems, which can work in conjunction with traditional water-based fire pumps to provide multi-layered fire protection.

Fire pumps on ships are one of the most vital safety features, offering the first line of defense in the event of a fire at sea. The SOLAS regulations and the updated FSS Code provide comprehensive guidance on the design, arrangement, and operational readiness of these systems, ensuring that ships can maintain effective firefighting capabilities under any circumstances. The importance of redundancy, accessibility, and capacity in fire pumps highlights their critical role in protecting lives and property onboard.