Lubricating oil systems play a pivotal role in the effective operation and longevity of two-stroke marine diesel engines on ships. These systems help in reducing friction between moving parts, dissipating heat, and protecting against corrosion. Compliance with conventions such as SOLAS and adherence to manufacturers’ guidelines, like those of MAN-B&W and Sulzer-Wartsila, is crucial.

Basic Principles

The essence of lubrication in marine engines lies in the critical role of lubricating oil. This oil establishes a protective film between moving components, mitigating friction, wear, and excessive heat. By doing so, not only ensures smooth operations but also significantly enhances the engine’s efficiency and lifespan. Furthermore, lubricating oil takes on the dual role of a coolant, adeptly dissipating the heat produced from friction and the combustion processes, preventing the engine from overheating. Beyond lubrication and cooling, the oil has an inherent capability to hold and suspend the by-products that result from combustion and mechanical wear. This ensures that the engine parts remain uncontaminated, facilitating cleaner operations and reducing the potential for undue wear and damage. In essence, the lubricating oil system in marine engines is a multifunctional mechanism, optimizing performance while ensuring longevity and cleanliness.

Lubrication: Lubricating oil forms a protective film between moving parts to reduce friction, wear, and heat generation, which is vital for the engine’s efficiency and durability.

Cooling: The system also acts as a coolant by carrying away the heat generated due to friction and combustion processes.

Cleaning: Lubricating oil holds in suspension the by-products of combustion and wear, keeping engine parts clean.

–

Main Lubricating Oil System

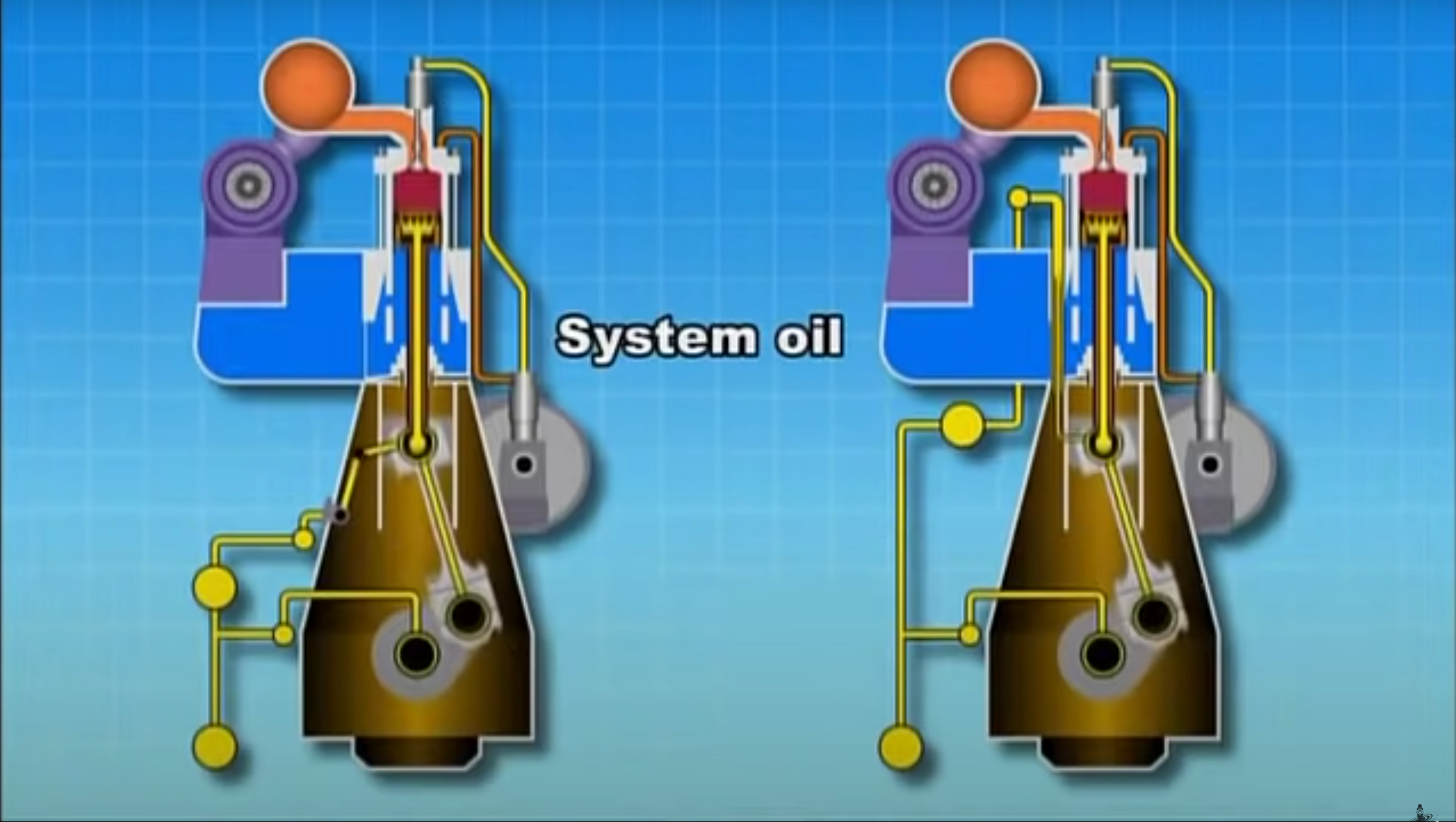

In marine vessels, two-stroke diesel engines are a common installation, and a well-maintained lubricating oil system is paramount for their optimal functioning. This system works meticulously to ensure that friction between moving parts is minimized, heat is efficiently dissipated, and components are safeguarded against corrosion. Each component of the lubricating oil system plays a crucial role in maintaining the engine’s efficiency and lonlife. At the heart of this system is the oil sump, acting as a reservoir, holding the supply of lubricating oil. It ensures that there is always an adequate amount of oil available for circulation throughout the engine. The oil pump, another vital component, works in tandem with the oil sump, circulating the oil throughout the engine and maintaining the necessary pressure. This continuous flow of oil is essential for the lubrication of various engine components, preventing wear and tear and ensuring smooth operation.

As the oil circulates through the engine, it picks up impurities and by-products of combustion. Oil filters are integral to the system as they ensure that these contaminants are removed, allowing only clean oil to circulate and protect the engine components. These filters need regular cleaning or replacement to maintain the purity of the oil and the health of the engine. Another essential component is the lubricating oil cooler. It regulates the temperature of the oil, ensuring it doesn’t get too hot, which might otherwise compromise the viscosity and lubricating properties of the oil. The cooler helps in maintaining the oil at an optimum temperature, balancing between adequate fluidity and lubricating ability.

Oil Sump: The oil sump contains the lubricating oil supply and acts as a reservoir.

Oil Pump: The oil pump circulates the oil throughout the engine, maintaining the necessary pressure.

Oil Filters: Filters remove impurities and contaminants from the oil, ensuring that only clean oil circulates.

Coolers: Lubricating oil coolers maintain the oil at the optimum temperature.

Bearings and Moving Parts: These are the main areas where lubrication is essential to prevent wear and tear.

—

Cylinder Lubricating Oil System introduced by MAN-B&W and Sulzer-Wartsila:

- MAN-B&W: MAN-B&W engines, such as the MC and ME series, employ a system-driven approach to lubrication. The Alpha Lubricator System, for example, precisely controls the timing and quantity of cylinder oil injection based on engine load, speed, and other parameters. This technology helps in optimizing oil consumption and minimizing wear.

- Sulzer-Wartsila: Sulzer-Wartsila engines, like the RTA and RT-flex series, utilize the Pulse Lubricating System (PLS) for cylinder lubrication. This system ensures uniform oil distribution on the cylinder liner surface, contributing to efficient lubrication and reduced cylinder wear.

System Maintenance and Monitoring

Frequent checks on oil levels, pressure, temperature, and contamination levels are essential. Any irregularities should be addressed promptly to prevent engine damage. Periodic oil analysis helps in determining the oil’s condition and the presence of any contaminants, enabling timely oil changes and adjustments. Regular cleaning or replacement of filters is vital to maintain oil cleanliness.

A well-maintained lubricating oil system is integral to the operational efficiency and lifespan of two-stroke marine diesel engines. By understanding the principles of lubrication, complying with international standards, and following manufacturers’ recommendations, ship personnel can ensure the optimal performance and safety of marine engines. MAN-B&W and Sulzer-Wartsila, with their advanced lubrication technologies, provide exemplary models in the industry for efficient lubrication practices. Regular inspections, timely maintenance, and adherence to safety guidelines contribute to a safe and efficient maritime environment.

–