Common ship incinerator problems explained clearly: combustion faults, alarms, sludge issues, and how marine engineers diagnose and fix them safely.

Onboard a ship, the incinerator is one of those machines that rarely attracts attention—until it stops working, fills the engine room with smoke, or triggers repeated alarms just before a port state control inspection. For marine engineers, incinerators sit in a delicate space between environmental compliance, fire safety, and daily operational reality. They burn waste that cannot simply be thrown away at sea, yet they operate using high temperatures, fuel oil, forced draft air, and mixed waste streams that behave very differently from clean fuels.

Unlike a main engine or generator, an incinerator often runs intermittently. This makes problems harder to detect early and easier to misunderstand when they appear. A smoky exhaust, a flame failure alarm, or damaged refractory lining may look like a simple fault, but in practice it usually reflects deeper issues in waste preparation, combustion control, or maintenance discipline.

This article explains the most common problems in ship incinerators, why they occur, and how experienced marine engineers diagnose and fix them in real operating conditions. The focus is practical and educational, using plain maritime English suitable for cadets, junior engineers, and experienced officers alike.

Why This Topic Matters for Maritime Operations

Ship incinerator problems are rarely isolated technical faults. They affect environmental compliance, engine-room safety, crew workload, and inspection outcomes. A poorly performing incinerator can lead to excessive waste storage, illegal incineration practices, fire hazards, or detentions during inspections by authorities applying international maritime rules set by bodies such as the International Maritime Organization. Understanding incinerator failures—and how to fix them correctly—protects both the ship and the people working onboard.

Understanding How a Ship Incinerator Works (Before Fixing It)

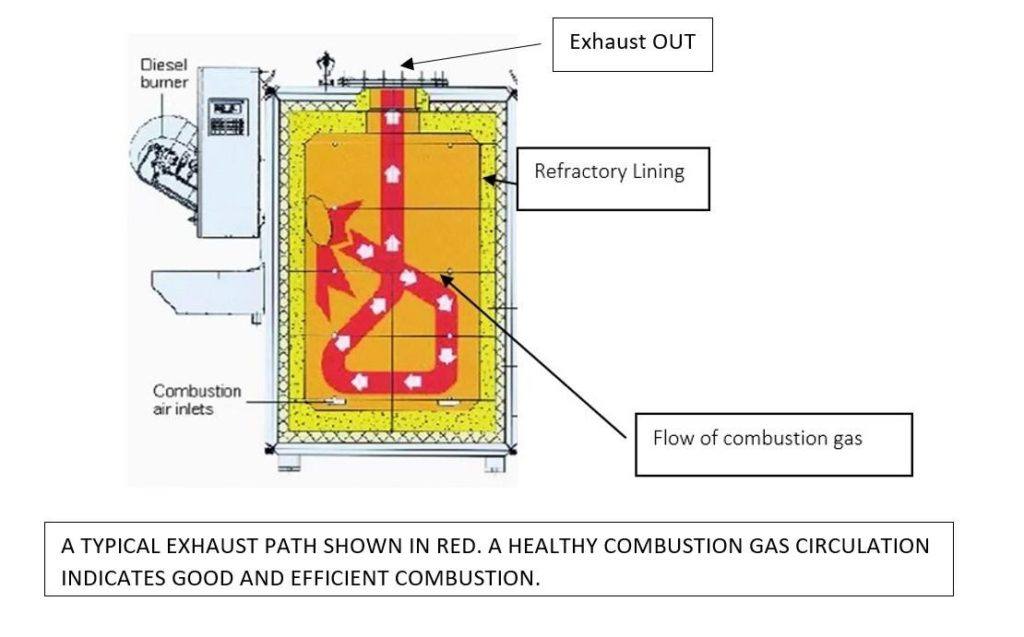

Before discussing failures, it is important to understand the basic operating principle. A ship incinerator is essentially a controlled combustion system designed to burn ship-generated waste at high temperature in a safe, enclosed chamber. Waste may be solid, liquid (sludge oil), or a combination of both. Air supply, ignition, flame stability, exhaust draft, and ash handling must all work together.

Unlike engines that burn relatively uniform fuel, incinerators burn highly variable material. One day the waste may be oily rags; the next day, wet food waste or sludge oil with high water content. This variability is the root cause of many problems.

Combustion Problems: The Most Common Source of Trouble

Poor Ignition and Flame Failure

One of the most frequent incinerator problems reported by engineers is flame failure during start-up. The burner ignites briefly and then trips, or the ignition sequence fails altogether.

In most cases, the issue is not the burner itself but the conditions at ignition. Sludge oil with high water content, cold combustion chambers, or incorrect air–fuel ratios make stable flame formation difficult. Engineers often resolve this by starting the incinerator on clean auxiliary fuel, allowing the chamber to reach stable operating temperature before introducing sludge oil or solid waste.

Experienced engineers treat incinerator ignition like lighting a fire in a cold furnace: rushing the process almost always leads to failure.

Incomplete Combustion and Black Smoke

Black smoke from the incinerator uptake is a clear sign of incomplete combustion. This typically results from insufficient air supply, overloaded waste charges, or poor waste preparation.

Engineers fix this problem by reducing the waste feed rate, checking forced-draft fans and dampers, and ensuring that waste is dry and properly segregated. In many cases, simply burning smaller batches more frequently produces far better results than loading the chamber heavily in one cycle.

White Smoke and Steam Clouds

White smoke is often mistaken for incomplete combustion, but it usually indicates excess moisture. Sludge oil mixed with water, wet food waste, or cleaning residues produces steam that exits the funnel as white vapour.

The solution is not more fuel or more air, but better waste conditioning. Engineers drain sludge tanks properly, allow waste to dewater, and avoid feeding wet waste until the chamber temperature is sufficiently high.

Sludge Oil–Related Problems and How Engineers Handle Them

High Water Content in Sludge Oil

Sludge oil is rarely pure oil. It contains water, solids, and chemical residues. When water content is high, combustion becomes unstable and flame failure is common.

Engineers typically address this by improving sludge tank heating, allowing sufficient settling time, and draining free water before incineration. Some ships also use dedicated sludge conditioning tanks to improve burn quality.

Sludge Pump and Heater Failures

Incinerator sludge systems rely on heaters and pumps that are often neglected. Heater failure leads to cold, viscous sludge that cannot atomise properly, while worn pumps struggle to deliver consistent flow.

The fix is preventive rather than reactive. Engineers who include sludge heaters and pumps in routine maintenance schedules experience far fewer incinerator problems than those who treat them as secondary systems.

Refractory Lining Damage: A Hidden but Serious Problem

Cracked or Spalled Refractory

The refractory lining protects the steel casing of the incinerator from extreme heat. Over time, thermal cycling, mechanical impact from waste loading, and chemical attack cause cracking or spalling.

Symptoms include overheating of the outer casing, reduced combustion efficiency, and alarm activation. Engineers inspect refractory linings during routine checks and dry-dock periods, repairing damaged sections before failure escalates into structural damage.

Causes Engineers Often Overlook

Rapid temperature changes are a major contributor to refractory damage. Shutting down the incinerator immediately after a high-temperature cycle, or restarting it while still hot without proper procedures, accelerates lining deterioration.

Experienced engineers allow controlled cool-down periods and avoid unnecessary start–stop cycles.

Air Supply and Exhaust Problems

Forced Draft Fan Failures

The forced draft fan supplies combustion air. When it underperforms or fails, combustion becomes unstable and smoky.

Engineers check fan motors, bearings, dampers, and air filters, ensuring that airflow matches the incinerator’s design requirements. Simple issues such as clogged filters or stuck dampers are often the root cause.

Uptake and Exhaust Blockages

Ash, soot, and unburned residues can accumulate in exhaust ducts over time. This restricts flow, reduces draft, and causes poor combustion.

Routine cleaning of exhaust paths is essential. Engineers who treat the incinerator uptake like a boiler uptake—inspecting and cleaning it regularly—avoid many operational issues.

Control System Alarms and Sensor Failures

Temperature and Flame Detector Faults

Incinerators rely on temperature sensors and flame detectors for safe operation. When these sensors fail or become contaminated, false alarms occur.

Engineers diagnose these issues by cleaning sensors, checking wiring connections, and verifying calibration. Replacing sensors is sometimes necessary, but unnecessary replacement can be avoided through proper inspection.

Interlock and Safety Trip Issues

Modern incinerators include safety interlocks linked to doors, fans, and burners. A single faulty limit switch can prevent operation.

Experienced engineers approach these faults systematically, checking each interlock condition rather than bypassing systems—a practice that creates serious safety risks.

Waste Segregation Errors That Create Technical Failures

Incinerators are often blamed for problems that actually originate in poor waste segregation. Burning prohibited materials, plastics, or contaminated residues leads to toxic fumes, clinker formation, and refractory damage.

Engineers fix this not with tools, but with procedures and communication. Clear waste segregation rules, signage, and crew training reduce incinerator failures more effectively than any mechanical adjustment.

Challenges and Practical Solutions in Daily Operation

One of the biggest challenges is time pressure. Engineers often operate incinerators during busy engine-room periods, increasing the temptation to rush cycles or overload waste.

The practical solution is routine. Ships that assign specific incinerator operation windows, with clear responsibility and checklists, experience fewer failures. Treating incinerator operation as a controlled activity—not an afterthought—makes a measurable difference.

Case Studies from Real Engine Rooms

On a bulk carrier trading long ocean passages, repeated flame failure alarms occurred every time sludge oil was introduced. The root cause was not the burner but excessive water content in the sludge. After improving sludge settling and draining practices, the incinerator operated reliably without hardware changes.

On a container feeder with frequent port calls, repeated smoke complaints led to inspection attention. Engineers traced the issue to mixed waste containing plastics and wet packaging. After improving segregation and reducing batch size, smoke emissions dropped immediately.

These cases illustrate a recurring theme: most incinerator problems are operational, not design failures.

Future Outlook and Maritime Trends

Incinerator technology is evolving alongside stricter environmental expectations. Improved combustion control, better monitoring, and integration with digital maintenance systems are becoming more common. At the same time, many operators aim to reduce incinerator use by relying more on port reception facilities.

However, incinerators will remain essential on many ships, especially those on long voyages or in regions with limited waste infrastructure. The role of the marine engineer will increasingly focus on safe, compliant, and well-documented operation, rather than simply burning waste.

Frequently Asked Questions

Why does my ship’s incinerator keep tripping on flame failure?

Most flame failures are caused by poor waste quality, high water content in sludge oil, or incorrect air–fuel ratios during start-up.

Is black smoke always a serious problem?

Black smoke indicates incomplete combustion. While not always dangerous, it signals inefficiency and potential compliance risk that should be corrected promptly.

Can wet waste be burned safely?

Wet waste can be burned, but only after the incinerator reaches stable high temperature. Excess moisture during start-up causes combustion problems.

How often should refractory linings be inspected?

Visual inspection should be routine, with detailed checks during maintenance periods and dry dockings.

Are incinerator problems usually mechanical or operational?

Most problems are operational—linked to waste preparation, loading practices, or procedure—not mechanical failure.

Should engineers bypass safety interlocks to keep the incinerator running?

No. Bypassing interlocks creates serious fire and safety risks and can lead to detention or accidents.

Conclusion and Take-away

Ship incinerators fail for predictable reasons: poor combustion conditions, bad waste preparation, neglected auxiliary systems, and rushed operation. Skilled marine engineers fix these problems not by improvisation, but by understanding how combustion works, respecting procedures, and maintaining the supporting systems that make incineration safe.

For maritime students and professionals, the key lesson is clear. An incinerator is not just a waste-disposal machine—it is a high-temperature system that demands the same respect, planning, and discipline as any other combustion equipment in the engine room. Mastering it is part of mastering modern ship operation.

References

-

International Maritime Organization (IMO) – MARPOL Annex VI and shipboard incineration guidance: https://www.imo.org

-

SOLAS Convention and fire safety principles (IMO): https://www.imo.org

-

Lloyd’s Register – Marine machinery and fire safety guidance: https://www.lr.org

-

DNV – Engine-room systems and safety publications: https://www.dnv.com

-

Marine Pollution Bulletin – Peer-reviewed research on ship waste and emissions: https://www.sciencedirect.com