Ship design and construction is a vast topic that involves the planning, designing, engineering, and construction of various types of ships. Some of the key aspects of ship design and construction include:

- Concept Design: The initial stage of ship design involves conceptualizing the ship’s purpose, size, and configuration, based on the customer’s needs and requirements.

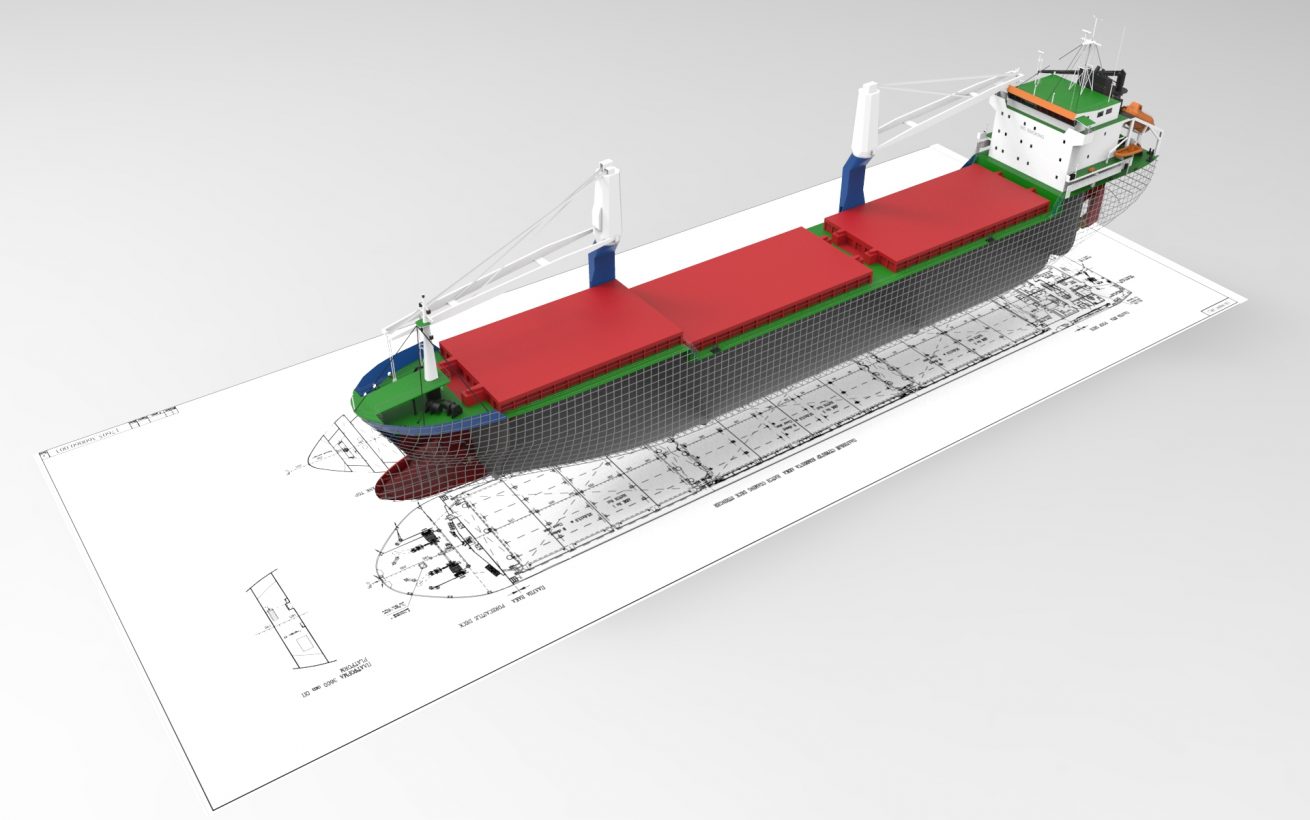

- Preliminary Design: This stage involves developing the general arrangement plan, which includes the layout of the vessel’s compartments, decks, and systems, as well as the specification of the main dimensions and capacity of the vessel.

- Detailed Design: In this stage, the technical details of the vessel are developed, including the engineering of the propulsion system, structural design, electrical systems, and piping.

- Construction: Once the design has been finalized, the construction of the ship begins. This involves the actual fabrication of the vessel, including the assembly of the hull, installation of equipment, and outfitting of the interior spaces.

- Testing and Commissioning: After construction, the ship undergoes a series of tests and trials to ensure that it meets all regulatory and operational requirements. Once the ship has been commissioned, it is ready to be delivered to the customer.

Some of the key factors that influence ship design and construction include the intended use of the vessel, the operating environment, regulatory requirements, and technological advances in materials and systems. Additionally, sustainability and environmental impact are becoming increasingly important considerations in ship design and construction.

Ship design and construction is a complex and costly process, as ships can be operated for multiple decades in an evolving marketplace and regulatory environment. The design of ships must consider their purpose, anticipated area of operation, and long-term regulatory environment. Environmental performance is also a key focus to reduce the ship’s carbon footprint, particularly in reducing greenhouse gas emissions. Autonomous ships are also being explored, and several pilot projects are already in the early stages of implementation.

Regulatory Framework for Shipbuilding

The International Convention for the Safety of Life at Sea (SOLAS) is regarded as the most important of all international treaties concerning the safety of merchant ships. The Convention regulates the minimum standards for the construction, equipment, and operation of ships compatible with their safety. Countries are responsible for ensuring that ships under their “flag” comply with its requirements, and a number of certificates are prescribed in the Convention as proof of compliance. Port State control allows countries to inspect ships of other countries if there are clear grounds for believing that the ship and its equipment do not comply with the Convention’s requirements.

Types and Sizes of Ships

The size of a ship is generally referred to in relation to its cargo capacity, or deadweight tonnage (DWT). DWT is a measure of a vessel’s weight carrying capacity and does not include the weight of the ship itself.

Bulkers

Ships carrying bulk cargo such as grain, potash, or coal, can also be classified according to their size. Some common terms include:

- Handysize bulker: 15k – 39k DWT

- Handymax bulker: 40k – 50k

- Supramax bulker: 50k – 60k

- Panamax bulker: 60k – 80k

- Post Panamax bulker: 80k – 110,000 DWT

- Capesize bulker: 160k – 210k DWT

Asia Dominates Ship Construction

South Korea is the world’s largest shipbuilder, followed by China. South Korea’s “big three” shipbuilders, Hyundai Heavy Industries, Samsung Heavy Industries, and Daewoo Shipbuilding & Marine Engineering, dominate the global market for large container ships. The market share of European ship builders began to decline in the 1960s as they lost work to Japan in the same way Japan most recently lost their work to China and South Korea. Modern shipbuilding makes considerable use of prefabricated sections. Entire multi-deck segments of the hull or superstructure will be built elsewhere in the yard, transported to the building dock or slipway, then lifted into place. This is known as “block construction.” The most modern shipyards pre-install equipment, pipes, electrical cables, and any other components within the blocks, to minimize the effort needed to assemble or install components deep within the hull once it is welded together.