Discover the 12 main ship propulsion systems—how they work, where they shine, and what’s next. From classic two-stroke diesels to hybrid-electric, pods, LNG and methanol dual-fuel, fuel cells, and wind-assist, this comprehensive guide blends clear explanations with real-world examples and the latest regulations and research.

Powering 80,000 ships—and the world economy ⚓️

If you have ever watched a fully laden container ship nose out of a breakwater or a cruise liner pirouette in port with ballet-like grace, you’ve witnessed one of engineering’s quiet miracles: propulsion. Behind the hull plating is a powertrain sized like a factory—converting chemical or electrical energy into thrust, hour after hour, in salt, heat, and swell.

Propulsion is changing fast. Climate policy, fuel markets, and digital controls are pushing beyond the diesel era into multi-fuel, hybrid-electric, and data-optimised configurations. Recent greenhouse-gas strategy updates call for a steep reduction in carbon intensity by 2030 and scalable uptake of zero or near-zero fuels this decade. Strategic outlooks from leading class societies and technology providers frame technical pathways and trade-offs operators must navigate to stay safe, compliant, and profitable.

What follows is a clear, practical tour of 12 major propulsion options, from workhorse two-strokes to advanced pods and fuel cells—explained without jargon, grounded in real ships, and connected to the decisions owners, officers, students, and port engineers make every day.

–

Why propulsion choice matters (beyond “how fast?”)

Selecting propulsion isn’t a beauty contest; it’s a business model:

- Fuel & emissions: The wrong choice can lock in high fuel bills and exposure to tightening carbon rules; the right one can lower OPEX and emissions simultaneously.

- Mission profile: A tug’s torque, a Ro-Ro’s hotel load, an offshore vessel’s dynamic positioning, or a ferry’s start-stop duty cycle pull choices in different directions.

- Lifecycle risk: Spares, crew familiarity, supplier ecosystem, and residual value all matter as fuels and standards evolve. Regulatory updates on shafts, bearings, and alternative fuels also shape machinery choices.

Think of propulsion as a three-legged stool: power source, transmission/control, and propulsor. Swap any leg (fuel, drivetrain, or propeller/nozzle/pod) and the whole system’s efficiency, manoeuvrability, and maintainability change.

–

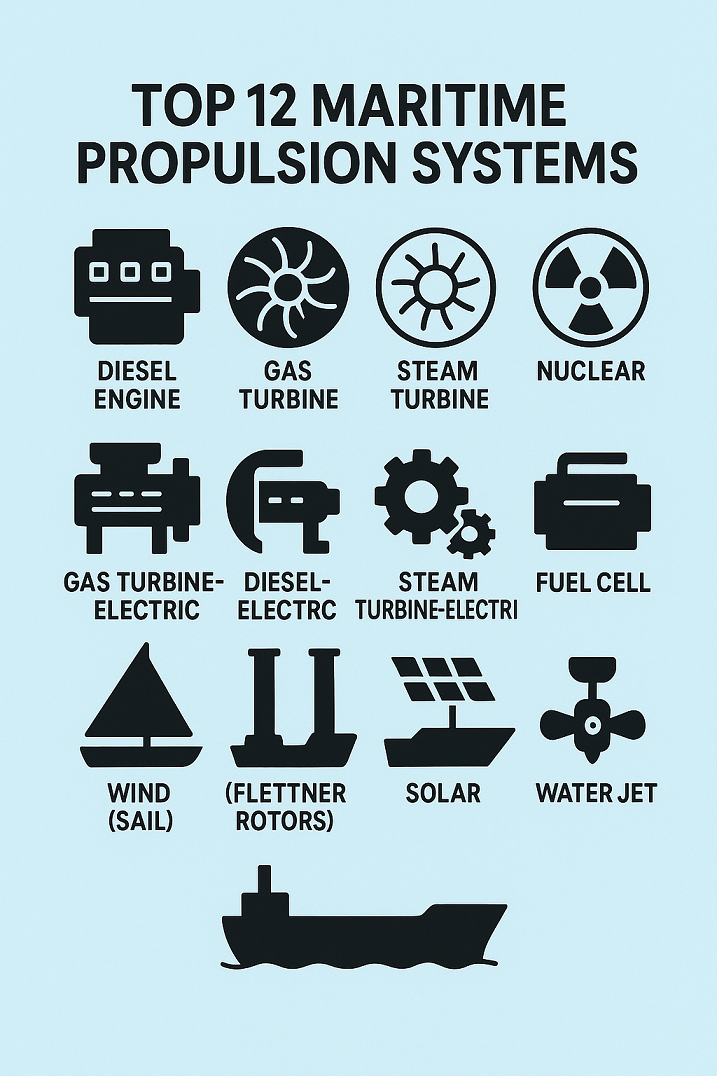

The Top 12 Maritime Propulsion Systems

The world of ship propulsion is undergoing a profound transformation. For over a century, the conventional diesel engine has been the backbone of global shipping. Today, however, the sector faces mounting pressure to decarbonise, comply with IMO’s GHG reduction strategy, and adapt to regional regulatory frameworks. This is pushing owners and shipyards to explore a wider portfolio of propulsion technologies. In this article, we examine the 12 most significant maritime propulsion systems, moving from traditional diesel setups to alternative fuels, electrical and podded drives, high-speed solutions, and finally the emerging frontiers of batteries, fuel cells, and wind-assist technologies.

1. Slow-Speed Two-Stroke Diesel with Fixed-Pitch Propeller (FPP)

This remains the undisputed classic of the deep-sea fleet. A slow-speed, long-stroke two-stroke diesel engine is mounted directly onto the propeller shaft, eliminating the need for a gearbox. The massive fixed-pitch propeller rotates slowly but produces tremendous thrust, making this arrangement ideal for tankers, bulk carriers, and container giants. These engines traditionally run on heavy fuel oils but now increasingly operate on very low sulphur fuel oil (VLSFO), marine gas oil (LSMGO), or dual-fuel variants.

The appeal of this propulsion system lies in its rugged simplicity, low specific fuel consumption, and unrivalled efficiency at service speeds. It is also a configuration that thrives under slow-steaming regimes, a strategy widely adopted to reduce emissions and operating costs. Yet, the landscape is changing: modern regulations such as EEXI and CII are driving retrofits like shaft power limitation devices, energy-saving ducts, and optimised propeller upgrades. Shipowners are also investigating conversion kits that allow these engines to operate on methanol or other alternative fuels, ensuring that today’s vessels remain competitive in tomorrow’s green economy.

2. Medium-Speed Diesel with Gearbox and Controllable-Pitch Propeller (CPP)

Unlike the direct-drive arrangement of two-stroke engines, medium-speed diesels rely on a reduction gearbox to connect to a controllable-pitch propeller. This configuration is favoured by ferries, Ro-Ros, offshore vessels, and naval auxiliaries, where flexible thrust, redundancy, and manoeuvrability are vital. The controllable-pitch mechanism allows the angle of the blades to be adjusted, enabling efficient operation across a wide range of speeds and load conditions.

One of the system’s great advantages is its ability to adapt to variable duty cycles, offering smoother part-load performance compared to fixed-pitch setups. It also integrates well with power-take-in and power-take-off modules, allowing for shaft generators, hybridisation, and even shore power compatibility. However, the mechanical complexity of gearboxes and hydraulic pitch systems requires disciplined maintenance. Without careful monitoring, wear and failure in these components can compromise both efficiency and safety.

3. Dual-Fuel LNG Engines (Two-Stroke or Four-Stroke)

Liquefied natural gas has emerged as the leading transitional marine fuel of the 2020s. Dual-fuel LNG engines can operate on both LNG and conventional liquid fuels, using small pilot injections for ignition. These engines exist in both low-pressure and high-pressure two-stroke variants as well as in four-stroke configurations.

LNG dramatically reduces sulphur oxide emissions and virtually eliminates particulate matter. Nitrogen oxide levels are also cut significantly, while carbon dioxide intensity is lower than traditional fuels. However, the true climate benefit depends on controlling methane slip—the unburned methane released into the atmosphere—which is a potent greenhouse gas. For this reason, continuous research is underway to improve combustion technologies, cycle efficiency, and slip abatement systems. LNG propulsion has gained significant traction in sectors with ready access to bunkering, such as cruise ships, container lines, and shuttle tankers. Yet, critics point out that LNG is not a permanent solution but a bridge fuel on the path to zero emissions.

4. Methanol Dual-Fuel Two-Strokes

Methanol propulsion is rapidly gaining momentum. Unlike LNG, methanol is liquid at ambient temperatures, which simplifies its storage and handling requirements. Dual-fuel two-stroke engines designed for methanol can switch between methanol and conventional fuels, offering operational flexibility.

The main attraction lies in methanol’s potential to be produced sustainably. Green methanol, derived from biomass or synthesized from renewable hydrogen and captured CO₂, can dramatically lower lifecycle greenhouse gas emissions. Shipowners such as Maersk and CMA CGM have placed substantial orders for methanol-powered vessels, signaling confidence in the fuel’s future.

Nevertheless, methanol comes with trade-offs. It has a lower energy density compared with diesel, meaning ships need larger tanks or more frequent bunkering. Safety concerns also arise because methanol is toxic and flammable, requiring strict handling protocols. The global supply network for methanol bunkering remains in its infancy, but investments are accelerating.

5. Ammonia-Ready and Dual-Fuel Concepts

Ammonia is one of the most anticipated future marine fuels, mainly because it contains no carbon. Dual-fuel two-stroke engines are being developed to burn ammonia with a small amount of pilot fuel, and several engine makers are already in the prototype stage.

Ammonia offers several advantages: its energy density by volume is higher than compressed hydrogen, and global logistics for ammonia are already well established through the fertilizer and chemical industries. However, the challenges are equally serious. Ammonia is highly toxic and poses risks to crew and the environment if leaks occur. Combustion of ammonia also generates nitrogen oxides and nitrous oxide, requiring sophisticated aftertreatment systems. Class societies and regulators are working quickly to develop the rulebooks, safety standards, and best practices necessary for ammonia adoption.

6. Diesel-Electric Propulsion (AC or DC Grids)

Diesel-electric propulsion represents a significant shift from mechanical to electrical power distribution. Instead of directly driving the propeller, multiple diesel generator sets feed electricity into an onboard grid, which in turn powers propulsion motors and hotel loads. This setup is particularly attractive for cruise ships, offshore support vessels, and icebreakers, where variable power demand and redundancy are critical.

The system offers remarkable flexibility. Engines can be run at optimal loads, while electric integration makes it easier to manage auxiliary systems such as heating, cooling, or dynamic positioning. The emergence of DC grids and smart energy management systems has further narrowed the efficiency gap with mechanical drive systems, reducing conversion losses and enhancing resilience. Still, diesel-electric vessels face higher upfront costs and require careful integration to achieve their full potential.

7. Hybrid-Electric Propulsion (Engines and Batteries)

Hybrid propulsion combines traditional engines with marine batteries, coordinated through an advanced energy management system. This setup enables zero-emission port manoeuvres, silent operations, peak shaving during high-load periods, and greater efficiency in dynamic positioning.

Hybrid technology has already proven itself in tugs, ferries, offshore supply vessels, and RoPax ships. The operational benefits are significant: reduced fuel consumption, lower maintenance costs, and the ability to meet increasingly strict port emission limits. Battery-electric ferries are even entering regular service corridors, relying on shore-based charging infrastructure.

The technology is not without challenges. Battery capacity must be carefully matched to the vessel’s mission profile, while fire safety and thermal management systems must be rigorously designed. Additionally, end-of-life recycling and sustainability of the battery supply chain remain important considerations.

8. Podded Electric Propulsion (Azipod® and Similar Systems)

Podded propulsion revolutionises manoeuvrability by integrating electric motors into steerable pods located outside the hull. These pods can rotate a full 360 degrees, eliminating the need for rudders and lengthy shaft lines. Ships equipped with podded systems enjoy superior agility, smoother hydrodynamic performance, and often more flexible internal layouts.

Cruise liners, icebreakers, and vessels with demanding dynamic positioning requirements are the primary beneficiaries of this technology. While the benefits are clear, podded systems require careful lifecycle planning. Maintenance of underwater equipment and the logistics of spare pods must be integrated into fleet strategies to ensure reliability.

9. Waterjets

Waterjets are the propulsion choice for high-speed vessels such as fast ferries, patrol craft, and luxury yachts. The principle is simple yet effective: an impeller draws in water and expels it at high velocity through a nozzle, creating thrust. The absence of protruding propellers makes waterjets well suited for shallow waters and operations requiring reduced underwater appendage risks.

Their strength lies in high-speed efficiency, rapid acceleration, and excellent manoeuvrability. However, at low speeds, waterjets are generally less efficient than conventional propellers. Cavitation, intake design, and careful maintenance are essential to sustaining performance.

10. Gas Turbines and Combined Cycles (CODOG, CODAG, COGES)

Gas turbines, adapted from aerospace technology, offer extreme power-to-weight ratios and compact design. They are often used in combination with diesel engines or steam recovery systems, giving rise to arrangements such as CODOG (combined diesel or gas), CODAG (combined diesel and gas), and COGES (combined gas turbine and steam).

These propulsion systems are most common in naval vessels and some high-speed ferries, where low vibration, quiet operation, and fast acceleration are highly valued. The drawbacks include high fuel consumption at part load, demanding maintenance, and costly fuel supply chains. Despite these challenges, their unmatched power density keeps them relevant in specialised applications.

11. Fuel Cells (PEM, SOFC) with Battery Buffers

Fuel cells represent a cutting-edge approach to marine power. Instead of combustion, they generate electricity electrochemically, using hydrogen or reformate fuels such as methanol and LNG. Proton exchange membrane (PEM) and solid oxide fuel cells (SOFC) are the most promising candidates for maritime applications.

The main advantages include high electrical efficiency, silent operation, and the near-total elimination of local pollutants. Fuel cell technology is advancing rapidly, with pilot projects on ferries and auxiliary systems already in place. However, widespread adoption depends on solving challenges in fuel logistics, hydrogen storage density, system cost, and safety regulations.

12. Wind-Assisted Propulsion (Rotor Sails, Wing Sails, Kites)

The shipping industry is revisiting an ancient ally: the wind. Modern wind-assist technologies such as Flettner rotors, rigid wing sails, and automated kites are now being deployed to supplement engine power and reduce fuel consumption. These systems are not intended to replace engines entirely but to work in tandem, typically delivering 5 to 15 percent fuel savings depending on the route and weather conditions.

Performance depends heavily on integration and digital optimisation. Weather routing systems can maximise the benefits while ensuring that schedules are not compromised. Challenges remain in terms of deck space, structural integration, and investment cost, yet successful deployments in bulkers, tankers, and Ro-Ros are proving that wind is once again a serious contender in maritime propulsion.

Assistive technologies that boost any propulsion choice

No matter which propulsion system a ship relies on—whether it is a conventional two-stroke diesel, a hybrid-electric setup, or an advanced fuel cell—there are several assistive technologies that can significantly improve performance. These solutions do not replace the main engines but rather work alongside them to enhance efficiency, reduce emissions, and improve operational resilience. Three of the most important categories are air lubrication systems, high-efficiency appendages, and digital optimisation tools such as digital twins and energy management systems.

Air Lubrication Systems (ALS)

One of the most effective technologies now being fitted to newbuilds and retrofits alike is the air lubrication system. By releasing a steady stream of micro-bubbles under the hull, these systems create a thin carpet of air that reduces skin friction between the hull and the surrounding water. Depending on hull form, vessel size, and operating speed, reported fuel savings typically range from five to ten percent. On large ships where fuel consumption represents the dominant operational cost, this margin translates into substantial annual savings as well as a measurable reduction in CO₂ emissions.

ALS has proven particularly effective on flat-bottomed vessels such as bulk carriers and LNG carriers, but it is now being trialled on cruise ships and Ro-Ros as well. The challenge lies in optimising bubble distribution and ensuring the system remains effective over time, particularly in rough seas or fouled hull conditions. Nevertheless, as energy-efficiency regulations become stricter, ALS is emerging as one of the most practical retrofittable solutions.

High-Efficiency Appendages

Another class of assistive technologies focuses on improving how water flows around the propeller and rudder. Devices such as pre-swirl stators, ducts, rudder bulbs, and propeller boss cap fins are designed to straighten and optimise the wake field before it reaches the propeller. Advanced propeller geometries, including tip-loaded or highly skewed blade designs, further enhance thrust efficiency by reducing cavitation and improving load distribution.

The cumulative effect of these appendages can be significant, often delivering fuel savings of three to eight percent. While each device on its own may seem incremental, together they can transform the hydrodynamic performance of a ship. Classification societies have already standardised many of these solutions, and shipyards routinely offer them as part of energy-efficiency upgrade packages. Importantly, these improvements are compatible with virtually all propulsion systems, from traditional shaft lines to azipods and waterjets.

Digital Twins and Energy Management

Beyond hardware, the rise of digital optimisation tools is revolutionising the way ships consume energy. A digital twin is a virtual model of a vessel’s propulsion, power, and auxiliary systems that runs in parallel with the real ship. By continuously comparing live operational data with model predictions, operators can identify inefficiencies and adjust settings in real time.

Coupled with advanced energy management systems, digital twins enable optimised loading of engines and batteries, smarter hotel load management, and even dynamic routing that reduces overall energy demand per tonne-mile. In practical terms, this means fewer grams of fuel burned per kilowatt-hour, lower emissions, and improved resilience under variable operating conditions. Digital optimisation also creates a foundation for integrating future technologies such as shore power, alternative fuels, or large-scale batteries without disrupting ship operations.

–

In-Depth Comparisons: How to match propulsion to mission

Deep-sea cargo (bulk, tanker, large container)

- Baseline: Two-stroke mechanical drive with large FPP (Option #1).

- Near-term decarb: Main-engine derating/propeller refit; shaft-gen PTO; ALS retrofit; slow steaming plus CII management; dual-fuel (LNG/methanol) for newbuilds.

- Future-proofing: Structural allowances for larger/segregated tanks; methanol/ammonia readiness; shore-power and on-voyage efficiency tech.

Ferries and RoPax

- Baseline: Medium-speed + CPP (Option #2) or diesel-electric (Option #6).

- Winning upgrades: Hybrid-electric with battery packs to enable zero-emission port transits, schedule-friendly ramp-ups, and noise reduction. Fully battery-electric high-speed passenger ferries are now practical on short routes with shore charging.

Offshore / DP vessels

- Baseline: Diesel-electric (Option #6) with podded thrusters (Option #8).

- Why: Load-following efficiency, redundancy, and precise positioning. Batteries add spinning reserve and transient smoothing (Option #7).

Cruise

- Baseline: Diesel-electric + podded propulsion for hotel load integration and unrivalled manoeuvrability.

- Direction of travel: LNG/methanol dual-fuel gensets, shore power, and waste-heat recovery, with ALS and weather routing to shave fuel and improve comfort.

High-speed craft / patrol

- Baseline: Waterjets (Option #9) with lightweight engines or turbines (Option #10).

- Focus: Intake design, cavitation suppression, and structure-borne noise for crew comfort and mission effectiveness.

Case Studies / Real-World Applications

1) Methanol two-strokes go mainstream

A new wave of large merchant newbuilds adopts dual-fuel methanol engines, citing drop-in compatibility with green methanol as supply grows. Owners value dual-fuel resilience while negotiating port-by-port availability.

2) Hybrid tugs and RoPax: small batteries, big impact

Harbour tugs benefit from high cycling and short transits; a modest battery-hybrid slashes idling and transient peaks, reducing fuel and noise without sacrificing bollard pull. Ferries see schedule reliability and zero-emission port entry as additional wins.

3) Cruise & ice: podded propulsion as a design enabler

Cruise contracts standardised on podded electric drives for turning circles, hotel integration, and redundancy. Designers enjoy machinery-space freedom that translates into better layouts and passenger experience.

4) Wind-assist on bulkers and tankers

Operators are installing Flettner rotors or wing sails, reporting double-digit percentage savings on some routes. Many pair wind-assist with air lubrication and optimised routing to compound gains and improve CII scores.

5) Battery-electric fast ferries

New orders in Europe and North America show fully battery-electric high-speed ferries with rapid shore charging and advanced energy-management systems, meeting local air-quality goals and reducing noise.

Challenges—and sensible solutions

The shift to new propulsion systems brings both opportunities and risks. One major issue is fuel uncertainty: with green methanol, ammonia, and hydrogen supplies still limited, owners fear locking into the wrong option. The solution lies in fuel-flexible designs, retrofit-ready tanks, and long-term agreements with suppliers, supported by modular energy systems that can adapt as markets evolve.

A second challenge is the pace of regulatory change. Classification codes and safety rules for shafts, bearings, and alternative fuels are being updated rapidly. Engaging early with class societies, working with vendors offering upgrade paths, and embedding safety-by-design principles are key to staying compliant.

Integration complexity also complicates hybrid, battery, and podded systems. These introduce new layers of electronics, management software, and vendor interfaces. Proven integrators, digital twin testing, and secure energy management architectures can reduce risks, while lifecycle planning for spares and remote support ensures long-term reliability.

Finally, regulatory pressure and the rising cost of carbon are tightening the economics of fossil-only propulsion. Efficiency upgrades such as air lubrication and wind-assist, combined with phased adoption of low-carbon fuels and digital routing tools, help owners stay ahead of measures like the IMO GHG strategy and the EU ETS.

In essence, success depends less on a single technology than on adaptability and proactive planning—balancing immediate savings with long-term readiness for a decarbonised future.

Future Outlook: Convergence on hybrid, modular, and data-led propulsion

The next decade likely belongs to hybrid-electric architectures wrapped around multi-fuel engines, with pods where manoeuvrability or layout benefits justify them. Batteries will keep growing in short-sea roles; fuel cells will expand as hydrogen and methanol supply chains mature. Wind-assist and air lubrication are on track to become mainstream efficiency add-ons—especially for CII management. The regulatory signal is one-directional: scale up zero/near-zero fuels by 2030 and keep marching toward 2050.

FAQs

1) What’s the single most efficient deep-sea propulsion today?

For large, steady-speed vessels, a slow-speed two-stroke with a large FPP remains hard to beat on pure propulsive efficiency. Hybrid measures like shaft-gen, air lubrication, and optimised propellers improve real-world performance.

2) LNG, methanol, or ammonia—what should I pick?

It depends on trade routes and contracts. LNG is mature but must address methane slip; methanol dual-fuel is scaling quickly with simpler storage; ammonia offers zero carbon but requires rigorous safety and aftertreatment, plus fuel availability. Use feasibility studies with your class society and vendors.

3) Are pods worth the capex?

For cruise, ice, and dynamic positioning tasks, often yes. Podded systems deliver manoeuvrability, space savings, and efficiency in many profiles. Lifecycle cost comparisons should include hotel-load integration and port-time savings.

4) Can batteries power big ships?

Not for oceanic line-haul alone (today). But they’re excellent for short-sea ferries, harbour craft, and hybridisation to cut fuel/emissions and sharpen transient response.

5) How much can wind-assist really save?

A practical planning band for many trades is 5–15%, with higher figures possible in favourable winds and with smart routing and device control.

6) Will fuel cells replace engines?

More likely they’ll complement engines in hybrids this decade—niches first (ferries, auxiliaries), then broader as fuel cost/logistics improve and standards stabilise.

7) What should students focus on?

Systems thinking: thermodynamics + power electronics + automation. Tomorrow’s engineers will tune EMS algorithms, understand multi-fuel safety, and evaluate lifecycle impacts as fluently as they size a propeller.

Conclusion: Choose propulsion like you’re choosing a strategy

Propulsion is no longer a static spec at the back of a GA drawing. It’s a strategic lever that shapes fuel bills, compliance, crewing, schedules—and your license to operate in a tightening policy world. If you’re speccing a ferry, evaluate hybrid DC grids and shore charging. Running deep-sea? Optimise your two-stroke with appendages and air lubrication now; design methanol or ammonia readiness into the next newbuild. If you’re a student or cadet, learn to speak “engine + electrons + emissions” with the same comfort as torque and thrust.

The sea won’t get any easier. But smarter propulsion can make shipping cleaner, safer, and more competitive—without losing what makes it magical.

References (selected, authoritative & hyperlinked)

-

IMO – 2023 IMO Strategy on Reduction of GHG Emissions from Ships

https://www.imo.org/en/MediaCentre/HotTopics/Pages/Cutting-GHG-emissions.aspx -

IMO – Policy direction for fuels/standards under MARPOL Annex VI

https://www.imo.org/en/OurWork/Environment/Pages/Air-pollution.aspx -

DNV – Maritime Forecast to 2050

https://www.dnv.com/maritime/publications/maritime-forecast-to-2050 -

DNV – Low-GHG fuel outlooks and uptake

https://www.dnv.com/maritime/insights/topics/energy-transition-in-shipping -

MAN Energy Solutions – MAN B&W ME-LGIM (methanol) two-stroke documentation

https://man-es.com/marine/products/low-speed-engines/me-lgim -

Wärtsilä – HY hybrid & ship electrification solutions

https://www.wartsila.com/marine/products/propulsion/propulsion-solutions/hybrid -

Wärtsilä – Battery-electric high-speed passenger ferries

https://www.wartsila.com/marine/customer-segments/passenger-vessels -

ABB – Azipod® propulsion efficiency & manoeuvrability

https://new.abb.com/marine/systems-and-solutions/azipod -

IACS / ClassNK – Shafting systems & Unified Requirements

https://iacs.org.uk/publications/unified-requirements -

Air lubrication research & industry cases (Silverstream and others)

https://www.silverstream-tech.com/ -

Wind-assist studies and industry resources (IWSA)

https://www.wind-ship.org/ -

Market-based measures and decarbonisation news (IMO & industry)

https://www.imo.org/

https://www.dnv.com/maritime/insights