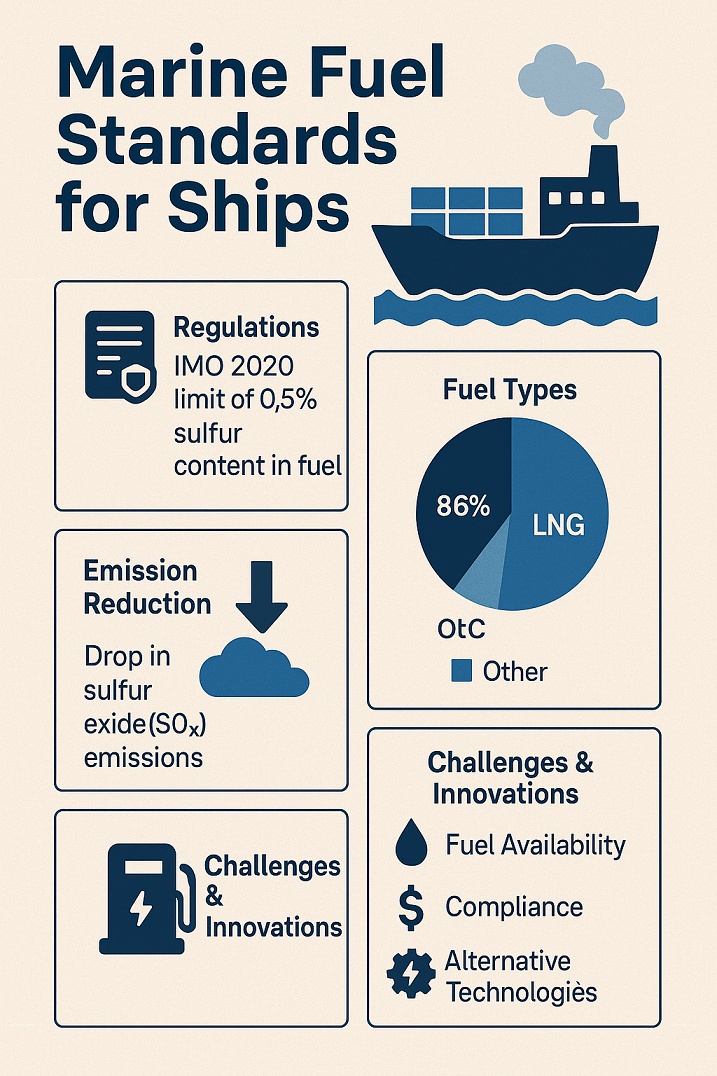

Understand marine fuel standards for ships with ISO 8217 & ISO 8216, MARPOL Annex VI, test methods, real cases, and future fuels. Practical, up-to-date guide.

The checklist that keeps a ship moving (and compliant)

If you’ve ever stood watch during bunkering, you know the drill: hose check, flow rates, manifold watch, soundings… and then the paperwork that can make or break a PSC inspection. Marine fuel standards aren’t abstract—they’re the difference between smooth sailing and a grinding halt at the berth.

If you’ve ever stood watch during bunkering, you know the drill: hose check, flow rates, manifold watch, soundings… and then the paperwork that can make or break a PSC inspection. Marine fuel standards aren’t abstract—they’re the difference between smooth sailing and a grinding halt at the berth.

Two families of rules define that difference:

-

International law (MARPOL Annex VI) that limits sulfur and tackles air pollution.

-

International standards (especially ISO 8217 and ISO 8216) that define fuel quality: what’s in your fuel, how it’s tested, and how it should behave in your machinery.

Think of MARPOL as what you’re allowed to emit, and ISO as what you’re allowed to burn. Together they keep ships compliant, engines safe, and the air cleaner. Over 80% of global trade (by volume) travels by sea, so the stakes couldn’t be higher.

–

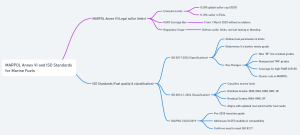

The two pillars: MARPOL Annex VI and the ISO standards

MARPOL Annex VI at a glance

MARPOL Annex VI is the legal backbone of air-emissions control in shipping. It sets both global and regional limits on pollutants, most notably sulfur oxides. Since 2020, the global sulfur cap for marine fuels has been 0.50% m/m, while Emission Control Areas (ECAs)—such as the Baltic Sea, North Sea, North American, and U.S. Caribbean zones—require an even tighter 0.10% m/m. The regime also introduced a key compliance tool: the carriage ban on high-sulfur fuel oil (HSFO) for ships that do not have an approved exhaust gas cleaning system. From 1 March 2020 onward, a ship without a scrubber cannot even carry HSFO intended for combustion. MARPOL therefore tells you what you are allowed to emit and, by extension, the sulfur level you must meet. What it does not do is explain how a fuel should be blended, tested, or proven fit for use in your engines—this is the realm of ISO standards.

ISO 8217 (specifications) and ISO 8216 (classification)

If MARPOL defines the legal destination, ISO explains the road you travel to get there. ISO 8217:2024 sets the technical specification for marine fuels used in diesel engines and boilers. It is the go-to reference that buyers, suppliers, and laboratories use to decide whether a delivered bunker meets the required grade and is safe to burn. It covers practical properties engineers care about—viscosity, flash point, water content, catalytic fines (aluminium and silicon), total sediment, acid number, hydrogen sulphide, and other characteristics that directly affect separator settings, injector wear, and combustion quality.

Complementing this, ISO 8216-1:2024 provides the classification system that gives marine fuels their familiar grade codes. It divides the market into distillate categories (like DMX, DMA, DMB, DMZ and the newer bio-distillate DF grades) and residual categories (RMA through RMK), creating a common language so that a DMA ordered in Rotterdam means the same thing as a DMA delivered in Singapore. The 2024 revision of ISO 8217 is especially significant because it reflects the fuel landscape after the 2020 sulfur transition. It recognizes the widespread use of very-low-sulfur fuel oils (VLSFOs) and the growing presence of renewable components, and it clarifies how those products should be specified and tested so that engines remain protected.

A simple rule of thumb helps: MARPOL governs how clean your exhaust must be; ISO 8217 governs how fit your fuel must be.

ISO 8217:2024—what changed and why it matters

The latest edition brings the specification in line with the fuels ships actually receive today. It reorganizes the residual grades to better reflect real-world VLSFO blends and introduces bio-residual “RF” grades so that fuels containing renewable components can be purchased and tested within a recognized framework. This sits neatly alongside the refreshed ISO 8216-1 classification, ensuring the grade names and groups are consistent worldwide. Another important aspect is the way ISO 8217:2024 explicitly accommodates biofuels, including higher FAME contents and renewable blends. It does so with added expectations around stability, compatibility, and reporting, so that the promise of lower-carbon energy does not come at the expense of injector sticking, filter plugging, or sludge formation. Just as crucial, the standard reiterates the division of responsibilities: it sets quality requirements for fuel fitness and safety, while sulfur compliance remains a statutory obligation that the purchaser must specify to satisfy MARPOL.

ISO 8216-1:2024—the map of marine fuel categories

Before discussing limits and test numbers, you need a shared taxonomy. ISO 8216-1 provides it. Distillate grades—DMX, DMA, DMB, DMZ, and the DF family for bio-distillates—are used where cleaner combustion and low cold-flow risks are needed, for example in ECAs or for smaller auxiliary engines. Residual grades—RMA up to RMK—cover the heavier products that typically require heating and careful separation before use. The introduction of RF grades acknowledges that renewable content is now part of mainstream bunkering. This clear, universal map ensures that a purchaser’s order, a supplier’s confirmation, and a lab’s report all refer to the same product identity, reducing misunderstandings that can lead to costly disputes or, worse, machinery damage.

PAS 23263—the bridge to 2020-compliant fuels

As the industry prepared for the 0.50% sulfur cap, ISO issued ISO/PAS 23263:2019 to guide stakeholders through the early VLSFO era. That document confirmed a vital point: 0.50% sulfur fuels still need to comply with ISO 8217’s quality framework. It also addressed two pain points that became evident in the first wave of VLSFOs—stability and compatibility. Different refinery streams can behave unpredictably when blended, so the PAS encouraged careful segregation, compatibility testing before mixing, and attention to parameters such as total sediment that signal a tendency to form sludge. In practice, this guidance helped operators avoid blocked filters, overloaded purifiers, and unplanned slowdowns during the transition to new fuel blends.

–

Inside ISO 8217: the parameters that protect engines (and crews)

Marine engineers don’t read specs for fun—they read them to keep engines alive. Here are the high-impact parameters, plus the ISO test methods behind them.

Flash point — safety first

-

What it is: the lowest temperature at which vapors ignite under test conditions.

-

Why it matters: MARPOL (SOLAS context) expects marine fuels to be ≥ 60°C (DMX exception for emergency).

-

How it’s tested: ISO 2719 (Pensky–Martens closed cup).

Viscosity — the pumpability & injection story

-

What it is: resistance to flow; dictates heating requirements for residual fuels and injection behavior for distillates.

-

How it’s tested: ISO 3104 (kinematic viscosity).

Density — separation and energy content

-

What it is: key for centrifuge settings and mass-to-volume conversions; a proxy for energy per unit volume.

-

How it’s tested: ISO 12185 (oscillating U-tube).

Water — the hidden engine enemy

-

Why it matters: free or emulsified water accelerates wear, fosters microbial growth, and drags cat fines through the system.

-

How it’s tested: For distillates, ISO 12937 (Karl Fischer coulometric titration).

Total sediment — storage stability in one number

-

What it is: measures sludge-forming tendency; instability leads to separator overload and filters plugging.

-

How it’s tested: ISO 10307-1 (existent total sediment) and 10307-2 (aged/accelerated).

Micro carbon residue (MCR) — deposit tendency

-

What it is: an indicator of coke formation risk.

-

How it’s tested: ISO 10370 (carbon residue—micro method).

Catalytic fines (Al+Si) — the cylinder-killer

-

What they are: tiny, abrasive FCC catalyst particles that grind pumps, injectors, and liners.

-

Spec reality: ISO 8217 limits for Al+Si depend on grade (commonly max 60 mg/kg for higher-viscosity residuals; lower limits for lighter grades). Engine makers still want ≤ 10–15 mg/kg at the engine inlet, so separators must do heavy lifting.

-

How it’s tested: ISO 10478 (aluminium & silicon by AAS/ICP).

Hydrogen sulphide (H₂S) — crew safety & corrosion

-

Why it matters: toxic gas risk and corrosion potential.

-

Typical limit: many ISO 8217 tables specify max 2 mg/kg.

Interpreting lab results: ISO 4259

When a test result sits near a limit, statistical repeatability & reproducibility matter. ISO 4259 provides the framework for deciding if a result is truly off-spec or within method precision—a common crux in bunker disputes.

–

How ISO 8217 and MARPOL Annex VI work together on board

-

Before bunkering: pick the right ISO grade for your engine, trade, and climate; agree the sulfur to meet MARPOL; align on sampling location and MARPOL sample bottle seals.

-

During bunkering: take the MARPOL sample at the manifold, seal and sign; check the Bunker Delivery Note (BDN) contains the ISO grade, density, sulfur declaration, quantity, date/place, and supplier details; keep BDNs onboard for three years.

-

After bunkering: send commercial samples to a lab for the full ISO 8217 suite (viscosity, density, water, total sediment, Al+Si, H₂S, acid number, etc.); set separators/heaters based on density and viscosity; monitor filters and back-flush frequency to catch instability early.

-

If the lab says “off-spec”: use ISO 4259 principles and retain the MARPOL sample chain of custody; escalate promptly to supplier, P&I, class, and flag as needed.

Real-world lessons: contamination cases and how standards helped

Houston 2018: phenolic contamination

Dozens—ultimately hundreds—of vessels experienced sticking fuel pumps and engine issues after bunkering in the US Gulf. Investigations detected phenolic compounds in fuel that otherwise looked acceptable under the usual specification checks. Clause 5 of ISO 8217 (“no added substance or chemical waste that jeopardizes safety”) became central in claims and settlements, alongside strong sampling practice and documentation.

Singapore 2022: chlorinated hydrocarbons

A large volume of HSFO in Singapore was contaminated with chlorinated organic compounds; many ships reported operational issues. The investigation traced the upstream source and resulted in enforcement actions. Once again, manifold sampling, BDNs, and the broader ISO 8217 framework (plus Clause 5) proved essential in resolving liabilities and guiding corrective actions.

Ongoing vigilance

Subsequent events in various regions have highlighted problematic components (including dicyclopentadiene and others), reminding operators that specification compliance alone isn’t enough; robust testing, segregation, and watchkeeping are critical. Industry bodies continue to refine best practice for stability, compatibility, and contaminant awareness.

Buying and handling fuel to ISO 8217: a practical walkthrough

1) Choose the right ISO grade for your ship and route

-

Cold climates: mind pour point, CFPP, and cloud point; consider distillate grades or low-pour residual grades.

-

ECAs: plan for 0.10% fuels or scrubbers; validate changeover procedures to avoid blackouts.

-

Slow-steaming liners: favor fuels with stable ignition/combustion qualities and low sediment tendencies.

2) Specify unambiguously in your stem

-

ISO 8217:2024 grade (e.g., RMG 380, or new RF/RM grades as applicable).

-

Sulfur limit to meet the voyage’s legal needs (statutory).

-

Request a recent certificate of quality and the ISO methods applied (2719, 3104, 12185, 12937, 10307-1/-2, 10370, 10478).

3) Sample and document correctly

-

MARPOL sample at the manifold; seal and sign; store for the period required by your flag/ISM procedures.

-

Verify BDN details and compliance statement; retain onboard for three years for PSC.

4) Treat fuel as if your engine depends on it (because it does)

-

Set purifiers using delivered density; log separator outlet turbidity and pressure; track filter differential pressure trends.

-

Target cat fines ≤ 10–15 mg/kg at the engine inlet; increase residence time and optimize temperature to enhance separation.

5) When in doubt, use ISO 4259 logic and escalate early

-

Test precision matters. A single result marginally outside a limit may require duplicate testing and careful interpretation under ISO 4259.

-

Preserve chain of custody and engage all stakeholders promptly.

Why marine fuel standards matter in modern operations

Protecting human health

Lower sulfur fuels and cleaner combustion reduce SOx and particulate matter—benefits felt most strongly in port cities and coastal regions. For crews, safer fuels and tighter controls also reduce exposure risks during bunkering and tank entry.

Ensuring fair competition

Without global rules, some operators might choose cheaper, dirtier fuels to cut costs. Standards level the playing field and prevent unfair competition, aligning commercial incentives with environmental obligations.

Avoiding catastrophic engine failures

Fuel instability, incompatibility, or contamination can cause sudden loss of propulsion. Adhering to ISO 8217 parameters, applying best-practice segregation, and watching total sediment, MCR, and cat fines drastically reduce these risks.

Supporting decarbonisation goals

Marine fuel standards are the building blocks for cleaner shipping. As the industry transitions toward low- and zero-carbon fuels, the ISO framework will continue evolving to ensure new fuels remain safe, stable, and engine-friendly.

The future of marine fuel standards: what to watch

Biofuels and RF grades at scale

ISO’s inclusion of bio-residual (RF) grades and broader treatment of FAME in 8217:2024 shows where the market is headed—toward blended or renewable fuels that still meet core safety and engine protection criteria. Expect further clarity on oxidation stability, net heat of combustion, cold-flow properties, and material compatibility as volumes grow.

Digital BDNs and chain of custody

While not an ISO specification, the industry is moving toward e-BDNs, tamper-evident seals, and blockchain-style custody to cut fraud and speed up dispute resolution—closing the loop between laboratory data, sampling events, and ship/shore acknowledgements.

Tighter GHG intensity rules

Beyond sulfur, international and regional policies will push carbon intensity targets and alternative fuels (methanol, ammonia, hydrogen). ISO 8217 and 8216 will continue adapting as these fuels enter mainstream bunkering, ensuring that “green” doesn’t compromise “safe.”

Case snapshots: applying ISO 8217 in practice

Scenario 1 — VLSFO stability concern in warm waters

A liner bunkers residual fuel in tropical summer. Lab shows acceptable sediment values, but filter differential pressure rises at sea. Onboard blending across tanks created incompatibility. Following ISO 8217 and compatibility guidance, the crew segregates incompatible streams, optimizes purifier temperature, and stabilizes operations.

Scenario 2 — High cat fines near the limit

A bulker receives fuel with Al+Si close to the specification limit. Knowing engine-maker guidance for the engine inlet, the chief engineer slows transfer and recirculates via purifiers to raise residence time. Condition monitoring confirms cat fines at or below the target before switching service tanks.

Scenario 3 — H₂S and tank entry

A distillate bunker screens with low liquid-phase H₂S (within the ISO limit but still hazardous for enclosed space work). The master mandates extra ventilation and gas checks before any tank entry, integrating company safety procedures with the specification context.

Frequently asked questions

What’s the difference between ISO 8217 and ISO 8216?

ISO 8216 classifies grades (DMX, DMA, RMG, RF, etc.); ISO 8217 sets the specification limits and references the test methods those grades must meet.

Does ISO 8217:2024 change sulfur limits?

No. Sulfur is a statutory requirement under MARPOL. ISO tables typically note the buyer must define sulfur to meet applicable law for the trading area or intended voyage.

How do I know if a marginal test result is truly off-spec?

Use ISO 4259 principles (repeatability/reproducibility) before declaring a failure. Many bunker disputes turn on this point; duplicate testing and method precision are key.

Are biofuels covered by ISO 8217?

Yes. ISO 8217:2024 adds more flexibility for bio content, including bio-residual (RF) grades, with additional performance expectations around stability and handling.

Which ISO tests matter most to engineers?

Common ones include ISO 2719 (flash point), ISO 3104 (viscosity), ISO 12185 (density), ISO 12937 (water in distillates), ISO 10307-1/-2 (total sediment), ISO 10370 (MCR), and ISO 10478 (Al+Si).

What should we aim for at the engine inlet for cat fines?

Most engine-maker guidance targets ≤ 10–15 mg/kg at the engine inlet. Adjust separators, temperatures, and residence times to achieve this.

Is the HSFO carriage ban still in force?

Yes—unless a ship has a compliant exhaust gas cleaning system (scrubber), it cannot carry HSFO for combustion under the post-2020 regime.

Conclusion: standards are your best defense

In the post-2020 world, fuel variability is a fact of life. ISO 8217:2024 gives you a stronger, clearer compass—covering modern VLSFOs and bio-components—while ISO 8216 keeps the map tidy. Pair them with MARPOL Annex VI and solid sampling/BDN discipline, and you reduce risk, protect your engine, and pass PSC with confidence.

On the practical side, treat ISO as living guidance. Keep your spec sheets current, follow the ISO test methods, and lean on ISO 4259 when disputes arise. And remember: your separators and filters are as much a part of compliance as the paper trail.

If you’re updating company procedures, this is a great moment to:

-

Refresh bunker clauses to ISO 8217:2024 grades.

-

Update SOPs with the latest ISO test methods.

-

Train crews on compatibility/stability checks and cat fines control.

-

Plan biofuel trials using the new ISO framework.

References (hyperlinked)

-

International Maritime Organization (IMO) — IMO 2020, Annex VI resources: https://www.imo.org

-

DNV — Global Sulphur Cap 2020 FAQ and carriage ban guidance: https://www.dnv.com

-

ISO — ISO 8217:2024 (Specifications of marine fuels): https://www.iso.org

-

ISO — ISO 8216-1:2024 (Categories of marine fuels): https://www.iso.org

-

IBIA — Overview of ISO 8217:2024 updates (new RM/RF grades): https://ibia.net

-

TransportPolicy / DieselNet — ISO 8217/8216 summaries and 2024 update notes: https://www.transportpolicy.net • https://dieselnet.com

-

CIMAC — Guidelines for interpreting marine fuel test results (TSA/TSP/TSE): https://www.cimac.com

-

ISO — ISO/PAS 23263:2019 (Considerations for 0.50% S fuels): https://www.iso.org

-

ISO — Key ISO methods referenced by ISO 8217: ISO 2719 (flash point), ISO 3104 (viscosity), ISO 12185 (density), ISO 12937 (water), ISO 10307-1/-2 (total sediment), ISO 10370 (MCR), ISO 10478 (Al+Si): https://www.iso.org

-

ExxonMobil Marine — H₂S context and distillate/residual characteristics: https://www.exxonmobil.com

-

UNCTAD — Review of Maritime Transport (global trade moved by sea): https://unctad.org

-

MPA Singapore — 2022 bunker contamination investigation & findings: https://www.mpa.gov.sg

-

USCG — Marine Safety Alert (Houston contamination 2018): https://www.dco.uscg.mil

-

CIMAC WG7 — Fuels incidents overview and best practice: https://www.cimac.com

-

Reuters / Professional Mariner — Subsequent contamination alerts and market updates: https://www.reuters.com • https://professionalmariner.com

-

WinGD — Engine-maker guidance on cat fines at engine inlet: https://wingd.com