Explore what the IGF Code means for shipping’s low-carbon future and how Risk-Based Alternative Technology (RBAT) helps adapt regulations for emerging fuels like hydrogen, ammonia, and methanol.

Why the IGF Code Matters in Modern Maritime Operations

As the maritime industry sails toward decarbonization, new fuels such as liquefied natural gas (LNG), hydrogen, ammonia, and methanol are becoming central to the conversation. These alternative fuels promise lower emissions, but they also introduce unfamiliar risks that traditional ship safety rules weren’t designed to manage. This is where the International Code of Safety for Ships using Gases or other Low-Flashpoint Fuels, or IGF Code, plays a vital role.

Developed by the International Maritime Organization (IMO) and enforced since 2017, the IGF Code sets internationally binding safety standards for ships using low-flashpoint fuels. However, it was originally designed with LNG in mind. As more complex fuels enter the market, the IGF Code must evolve—and that’s where Risk-Based Alternative Technology (RBAT) comes into play.

RBAT allows shipowners, designers, and classification societies to propose novel solutions that meet or exceed existing safety levels, even when there is no prescriptive rule yet. It’s a flexible, forward-thinking approach to regulation, essential for innovation in a rapidly changing energy landscape.

Understanding the IGF Code: Framework and Scope

The IGF Code applies to all vessels using low-flashpoint fuels, starting with LNG and extending gradually to others through amendments and risk-based evaluations. It operates under the umbrella of the SOLAS Convention (Chapter II-1, Regulation 55) and includes provisions for design, construction, equipment, training, and operation.

Some of the key features of the IGF Code include:

- Requirements for fuel containment systems

- Fire detection and extinguishing systems

- Ventilation of machinery spaces

- Hazardous area classification

- Emergency shutdown systems (ESD)

As of 2024, the Code is still in its Phase 1 implementation, primarily focused on LNG. Yet the IMO has initiated new working groups to expand it to hydrogen, ammonia, and methanol by 2027.

How Risk-Based Assessment Tool (RBAT) Bridges the Gap in Maritime Innovation

Risk-Based Alternative Technology is not just a loophole or optional pathway; it’s a structured regulatory tool embedded within the IGF Code (Part A-1, 2.3 and 2.4). It enables approval of safety equivalencies when novel fuels or technologies do not fully conform to prescriptive standards. Under RBAT, stakeholders must:

- Conduct a Hazard Identification (HAZID) and Hazard and Operability Study (HAZOP)

- Provide a Quantitative Risk Assessment (QRA)

- Demonstrate that risk mitigation is at least equivalent to prescriptive measures

- Submit documentation for Flag State and Class approval

Classification societies like DNV, Lloyd’s Register, and Bureau Veritas have issued RBAT guidance papers for emerging fuels, supporting this collaborative approach.

RBAT was used to greenlight:

- The world’s first hydrogen-powered ferry (MF Hydra)

- The ammonia-ready tanker designs by Samsung Heavy Industries

- Methanol dual-fuel retrofits on Maersk’s fleet

These cases illustrate the Risk-Based Assessment Tool (RBAT)’s real-world potential to catalyze change.

–

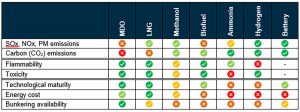

Comparison of different alternative fuels

The setup below is divided into Emissions, the benefits and/or downsides regarding Safety (flammability and toxicity) and Maturity (technologically, cost of energy and bunkering availability). Marine Diesel Oil (MDO) is today’s widespread choice, but it is also yesterday’s choice. The carbon footprint is too large to continue using this fuel as the sole choice for the future. When considering alternatives, it is difficult to determine which fuel will be the sound choice. No single solution is viable for all vessel types, and evaluations of the earlier-mentioned criteria need to be done for each project. Looking into possible future needs and scenarios is also an important part of this.

Key Developments Driving Change

Expansion of the IGF Code Beyond LNG

The IMO’s Sub-Committee on Carriage of Cargoes and Containers (CCC), in collaboration with IACS and ISO, is actively expanding the IGF Code to cover:

- Hydrogen (expected 2027)

- Ammonia (expected 2028)

- Methanol (fast-tracked in 2025 due to commercial uptake)

This expansion is guided by IMO Circulars like MSC.1/Circ.1621 for methanol and MSC.1/Circ.1647 for hydrogen, both setting interim safety guidelines.

Classification Society Engagement

Leading class societies have developed alternative fuel notations and rules:

- DNV’s “Gas Fuelled Ammonia” and “Hydrogen Ready” notations

- ABS’s Guide for Safety of Ships Using Ammonia

- ClassNK’s Rules for Fuel Cells and Hydrogen

These rules are often harmonized with IMO’s goals but tailored to real-world ship design timelines.

Growing Investment in Pilot Projects

According to Clarksons Research, as of 2024, there are:

- Over 250 methanol-capable ships on order

- 30+ hydrogen pilot projects

- 15 ammonia-fueled concept ships under development

RBAT has been instrumental in bringing these ships closer to operation by accelerating regulatory clearance in parallel with shipbuilding.

–

Challenges and Solutions in Applying RBAT

Regulatory Uncertainty

One of the foremost challenges in applying Risk-Based Alternative Techniques (RBAT) to emerging fuels lies in the absence of a harmonized global regulatory framework. Fuels such as hydrogen and ammonia, while offering promising decarbonization potential, are not yet fully integrated into existing maritime conventions and codes. As a result, regulatory approval processes become complex, protracted, and heavily dependent on the interpretations of individual Flag States. Different authorities may apply varying thresholds for acceptable risk, leading to fragmented implementation and delaying project timelines.

To address this issue, collaborative governance mechanisms have begun to take shape. For instance, the International Maritime Organization (IMO) has established specialized Correspondence Groups on fuel safety, bringing together Flag States, classification societies, ship operators, fuel suppliers, and technical experts to develop shared understanding and guidance. These forums aim to accelerate alignment around risk management principles for new fuels. Additionally, digital platforms like the IMO’s Global Integrated Shipping Information System (GISIS) support transparency and coordination by allowing stakeholders to share alternative design cases, risk assessments, and best practices. Over time, these tools are helping to build a common language for evaluating novel fuel systems, thereby easing the regulatory pathway for RBAT-based solutions.

Limited Experience and Data

Quantitative Risk Assessments (QRAs), a core component of RBAT, depend on empirical data—especially incident histories—to estimate the likelihood and consequences of failure scenarios. However, hydrogen and ammonia remain in the early stages of maritime deployment, meaning real-world operational data are scarce. Without a sufficient statistical foundation, safety models can be either overly conservative or insufficiently robust, hindering the development and acceptance of alternative fuel technologies.

To overcome this limitation, international demonstration projects and research initiatives have taken the lead in generating relevant data. The EU-funded FLAGSHIPS project, for example, is deploying hydrogen-powered vessels in commercial service and systematically collecting operational metrics, near-miss records, and system performance data. Similarly, RISE Research Institutes of Sweden are working on hazard identification and control validation based on full-scale testing and pilot projects. These initiatives contribute to an evolving knowledge base that not only supports more accurate QRAs but also increases confidence among regulators and industry stakeholders in the safe implementation of emerging fuels.

Crew Training and Human Factors

The transition to alternative fuels introduces a suite of new operational risks and unfamiliar technical systems. Unlike conventional marine fuels, hydrogen and ammonia require specialized handling procedures, leak detection mechanisms, and emergency protocols. These differences necessitate significant retraining for ship crews, who must develop new competencies in areas such as cryogenic fuel management, toxicity mitigation, and explosion prevention. Human error, already a leading cause of maritime incidents, becomes a heightened concern when personnel are unfamiliar with novel technologies.

To mitigate this challenge, the International Maritime Organization is in the process of updating the Standards of Training, Certification and Watchkeeping for Seafarers (STCW) Code to include specific competencies related to low- and zero-carbon fuels. National maritime authorities and training institutions are also adapting rapidly. For instance, Massachusetts Maritime Academy in the United States and Maritime Knowledge India have both introduced simulation-based training programs that replicate hydrogen and ammonia fuel scenarios. These immersive educational tools allow mariners to practice complex procedures in a risk-free environment, thereby improving safety outcomes and operational readiness.

Insurance and Liability

A further complication in the deployment of RBAT is the hesitancy of marine insurers and Protection and Indemnity (P&I) clubs to underwrite the risks associated with emerging fuels. The lack of standardized safety metrics and verified design outcomes makes it difficult for underwriters to assess risk exposure accurately. In the absence of proven risk controls, premiums can become prohibitively high—or coverage may be denied altogether—discouraging early adopters and slowing investment in innovative fuel systems.

However, RBAT offers a potential solution by providing a structured and transparent method for risk verification. When alternative fuel system designs are subjected to rigorous RBAT analysis and subsequently validated by recognized classification societies, the resulting documentation serves as a critical assurance mechanism for insurers. Encouragingly, the International Group of P&I Clubs has acknowledged the need for harmonized safety verification standards and is actively participating in dialogues with the IMO and other stakeholders to establish best practices. As more case studies and safety assessments become publicly available, insurance markets are expected to evolve in step with technological innovation, offering more tailored and accessible coverage for alternative-fuel vessels.

–

Real-World Applications: Lessons from Practice

Maersk’s Methanol Fleet Rollout

Maersk launched its first methanol-fueled container vessel in 2023 and expects over a dozen by 2026. RBAT played a key role in:

- Validating dual-fuel engine safety

- Approving methanol bunkering procedures

- Installing additional fire suppression systems near fuel tanks

This rollout is supported by guidance from IMO Circular MSC.1/Circ.1621 and ABS’s methanol rules.

MF Hydra: Hydrogen Ferries in Norway

As the first vessel using compressed hydrogen fuel cells, MF Hydra had no prescriptive path under the IGF Code. RBAT allowed:

- Location of fuel tanks on deck

- Use of explosion-proof compartments

- Crew drills simulating hydrogen leaks and fires

Approved by DNV and the Norwegian Maritime Authority, MF Hydra became a model for future hydrogen vessels.

Ammonia-Ready Tanker Designs

Samsung Heavy Industries, in partnership with MAN Energy Solutions, unveiled ammonia-ready tankers with pre-installed dual-fuel engines. RBAT evaluations are helping to:

- Define acceptable leak concentrations

- Evaluate corrosion risk mitigation

- Model emergency venting scenarios

Lloyd’s Register and BV are collaborating on standardizing RBAT pathways for ammonia in shipboard systems.

–

Future Outlook: A Living Framework

RBAT is not a one-time solution—it’s a continuous improvement loop. As more fuels and technologies are tested, feedback loops between shipowners, Class, and IMO will refine global regulations.

Looking ahead, expect:

- Formal RBAT annexes in the IGF Code by 2028

- Global hydrogen/ammonia bunkering guides from IAPH

- More digital tools like DNV’s MarOS platform to model and simulate fuel risk in design stages

UNCTAD’s 2024 Maritime Transport Review urges faster adoption of RBAT, noting it may be the only way to meet IMO’s 2050 net-zero targets.

–

FAQ: Understanding IGF Code and RBAT

What is the IGF Code? The IGF Code is an IMO safety regulation for ships using low-flashpoint fuels like LNG, hydrogen, methanol, or ammonia.

Why was RBAT introduced? RBAT provides a flexible way to meet safety goals when no clear regulation exists for new fuels or technologies.

Is RBAT only for new ships? No, RBAT can be used for newbuilds, retrofits, or even system-level upgrades involving novel energy systems.

Does RBAT guarantee approval? Not automatically. A rigorous risk analysis and Class/Flag approval are required.

Are all Flag States aligned on RBAT? Not yet. Alignment is improving via IMO working groups and bilateral agreements.

How long does the RBAT process take? It can take 6–18 months depending on the fuel type, system complexity, and Flag State requirements.

Is RBAT relevant beyond alternative fuels? Yes, it’s also applied to battery systems, autonomous ship controls, and advanced fire safety technologies.

–

Conclusion: Navigating the Future with Confidence

As maritime fuel options multiply, staying compliant—and competitive—requires more than just following rules. It calls for innovation, collaboration, and courage to explore beyond the conventional. The IGF Code provides the safety net, and RBAT is the bridge that allows us to safely cross into uncharted waters.

Shipowners, designers, and regulators who embrace RBAT are not just ticking regulatory boxes—they’re shaping the future of maritime safety. And in doing so, they help the entire industry chart a more sustainable course.

References

- IMO IGF Code Overview

- MSC.1/Circ.1621 on Methanol Safety

- DNV’s Alternative Fuels Guidelines

- ABS Guide for Safety of Ships Using Ammonia

- Clarksons Research Alternative Fuel Vessel Orderbook

- UNCTAD Review of Maritime Transport 2024

- RISE of Sweden Fuel Safety Initiatives

- International Group of P&I Clubs

- Maritime Knowledge India

- Maersk Green Methanol Fleet

- Samsung Heavy Industries Ammonia Projects

- DNV MF Hydra Case Study

- IMO GISIS Platform

By Dr R.Karimpour