In a landmark achievement for maritime decarbonization, the world’s first ship-to-ship (STS) transfer of ammonia at anchorage was successfully completed at Port Dampier in Western Australia’s Pilbara region, in late month of 2024. This historic operation, conducted by a consortium led by the Global Centre for Maritime Decarbonisation (GCMD), Yara Clean Ammonia (YCA), and the Pilbara Ports Authority, marks a critical milestone in establishing ammonia as a viable zero-emission fuel for the shipping industry.

Credit: Yara

A Milestone for Clean Shipping

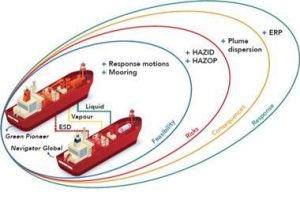

The trial involved the transfer of 4,000 cubic meters (approximately 2,715 tonnes) of ammonia between two gas carriers—the 35,000 cbm Green Pioneer (owned by Mitsui O.S.K. Lines, MOL) and the 22,500 cbm Navigator Global (owned by Navigator Gas). The operation simulated real-world bunkering conditions, demonstrating that ammonia can be safely and efficiently transferred in a working port environment.

“This demonstrates that ammonia transfer can be done with the highest safety standards and efficiency in a working port environment. The transfer is a major milestone to decarbonize shipping using low-emission ammonia as fuel,” said Murali Srinivasan, SVP Commercial at Yara Clean Ammonia .

Ammonia, when produced using renewable energy or carbon capture, emits no CO₂ when burned, making it a promising candidate for decarbonizing global shipping, which accounts for 3% of global greenhouse gas emissions .

Credit: gcformd

Why This Trial Matters

1. Proving Safety and Feasibility

The operation was conducted under strict safety protocols, including:

- Emergency Release Couplings (ERC) and shutdown systems.

- Computational Fluid Dynamics (CFD) modeling to assess ammonia dispersion risks.

- A standby firefighting tug (Coral Knight) and spill response teams .

A Hazard Identification (HAZID) study confirmed no high-risk scenarios, while plume dispersion modeling showed that any potential ammonia release would remain within safe limits .

2. Accelerating Ammonia Bunkering Infrastructure

With no dedicated ammonia bunkering vessels yet available, STS transfers serve as the closest proxy for future fuel supply chains. The Pilbara region, already a hub for ammonia exports, is positioning itself as a future green ammonia bunkering hub .

3. Collaboration Driving Progress

The success was made possible through tripartite collaboration:

- Yara Clean Ammonia provided the ammonia and operational expertise.

- Pilbara Ports Authority ensured regulatory and logistical support.

- GCMD coordinated the trial, drawing on insights from a 2023 safety study .

–

The Path Forward: Scaling Ammonia as a Marine Fuel

The Pilbara trial is just the beginning. Yara Pilbara is already advancing its Project Yuri renewable hydrogen plant, which will integrate green ammonia production by 2025 . Meanwhile, GCMD plans to replicate this model in other ports, refining safety guidelines ahead of commercial-scale operations .

“This pilot marks a crucial step towards readying the ecosystem for using ammonia as a marine fuel,” said Professor Lynn Loo, CEO of GCMD .

Global Momentum: More Ammonia STS Transfers Follow

Following the Pilbara success, other key players have conducted similar trials:

- Trafigura completed a 6,000-tonne ammonia STS transfer near Ceuta, Spain, in July 2024, signaling growing industry adoption [citation:Trafigura release].

- The Port of Rotterdam conducted its first ammonia STS transfer in April 2025, transferring 800 cubic meters between LPG carriers as part of its hydrogen fuel strategy [citation:Rotterdam release].

These developments underscore a global shift toward ammonia as a shipping fuel, with projects like the Pilbara-to-East Asia green corridor expected to require 1–1.5 million tonnes of ammonia by 2035 .

–

Conclusion: A New Era for Maritime Fuel

The world’s first ammonia STS transfer at anchorage is more than a technical achievement—it’s a catalyst for the energy transition in shipping. With safety proven, infrastructure evolving, and industry collaboration strengthening, ammonia is poised to play a pivotal role in meeting the IMO’s 2050 decarbonization targets.

For further details, access the full GCMD report here.

About the Key Partners

-

Yara Clean Ammonia: The world’s largest ammonia distributor, driving clean fuel adoption.

-

Global Centre for Maritime Decarbonisation (GCMD): A Singapore-based nonprofit accelerating shipping’s zero-carbon transition.

-

Pilbara Ports Authority: A leader in bulk commodity exports, now pioneering green fuel infrastructure.

Media Contacts:

-

Yara Clean Ammonia: Hilde Steinfeld, +47 99 35 30 30, hilde.steinfeld@yara.com

-

GCMD: media@gcformd.org

That!s right.

Thanks, I’ve recently been searching for information approximately this subject for a while and yours is the greatest I have found out so far. However, what concerning the conclusion? Are you certain concerning the supply?